Method for preparing metal network transparent conductive electrode by low-cost plasma bombardment

A transparent conductive electrode and plasma technology, which is applied in cable/conductor manufacturing, circuits, electrical components, etc., can solve problems such as hidden dangers in safety, low market competitiveness, waste of precious metals, etc., and achieve diversification and small production capacity restrictions , The effect of low input cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

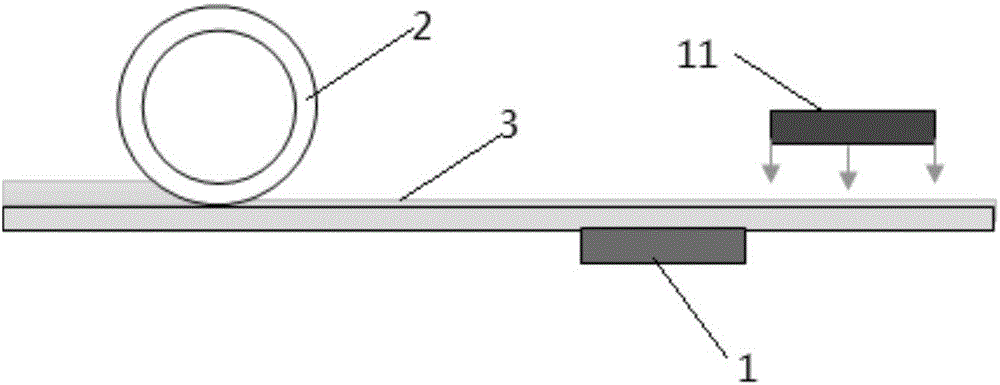

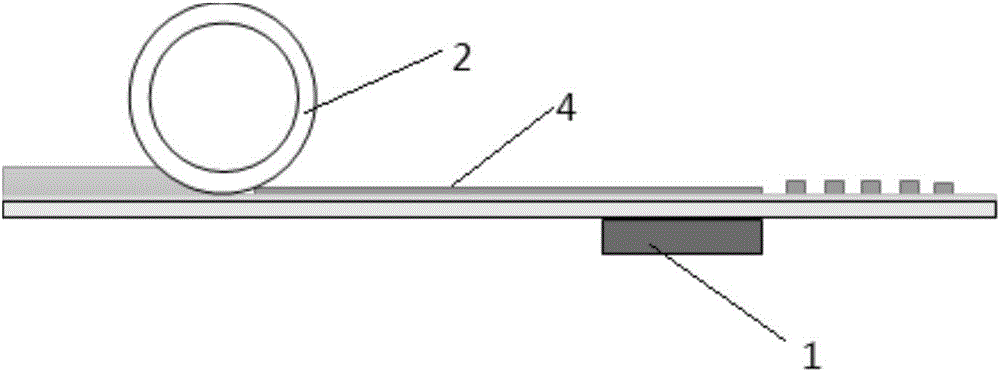

[0048] like Figure 1-5 As shown, this embodiment provides a low-cost method for preparing a metal network transparent conductive electrode by plasma bombardment. It includes five main steps: one is the selective fixation of the substrate and the removable layer, the other is the deposition of cracking fluid and cracks into a template, the third is the formation of metal network grooves by plasma bombardment, and the fourth is the formation of nano-metal particles. The coating and annealing form a network, and the fifth is UV curing and compaction to control the surface morphology and obtain transparent conductive electrodes.

[0049] The detailed process of each step is as follows:

[0050] (1) Selection and fixation of substrate and removable layer

[0051] (1) The selected substrate material is PET, 5cm×5cm, cleaned with a spray gun, including spraying twice with acetone, twice with ethanol, and three times with deionized water, and then blown dry with nitrogen to keep it...

Embodiment 2

[0070] like Figure 1-5 As shown, the method for preparing a metal network transparent conductive electrode by low-cost plasma bombardment provided in this embodiment includes the following steps:

[0071] The detailed process of each step is as follows:

[0072] (1) Selection and fixation of substrate and removable layer

[0073] (1) The selected substrate material is PET, 5cm×5cm, cleaned with a spray gun, including cleaning twice with acetone, twice with ethanol, and three times with deionized water, and then dried with nitrogen to keep it clean;

[0074] (2) The selected removable layer is photoresist 3, SU-8 negative photoresist, which is evenly sprayed on the substrate, and a Meyer rod 2 with a diameter of 10 mm and a wet film thickness of 15 μm is rolled at a constant speed to form a film. In oven 1, keep warm at 150°C for 6 minutes. Set the power of the ultraviolet lamp 11 to 1000W, and expose at a height of 10 cm vertically above the sample for 10 seconds to obtain...

Embodiment 3

[0092] like Figure 1-5 As shown, the method for preparing a metal network transparent conductive electrode by low-cost plasma bombardment provided in this embodiment includes the following steps:

[0093] The detailed process of each step is as follows:

[0094] (1) Selection and fixation of substrate and removable layer

[0095] (1) The selected substrate material is glass, 5cm×5cm, cleaned with a spray gun, including cleaning twice with acetone, twice with ethanol, and three times with deionized water, and then dried with nitrogen to keep it clean;

[0096] (2) The selected removable layer is photoresist 3, BN303-60 negative photoresist, which is evenly sprayed on the substrate, and the Meyer rod 2 with a diameter of 10 mm and a wet film thickness of 6 μm is rolled at a constant speed to form a film , in oven 1, keep warm at 20°C for 4min, set UV lamp 11, power 100W, and expose at a height of 10cm vertically above the sample for 30s; repeat the above steps 5 times to obta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Transmittance | aaaaa | aaaaa |

| Transmittance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com