Equipment working condition combination-based energy dispatching system

A technology for energy scheduling and working conditions, which is used in control/regulation systems, general control systems, comprehensive factory control, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

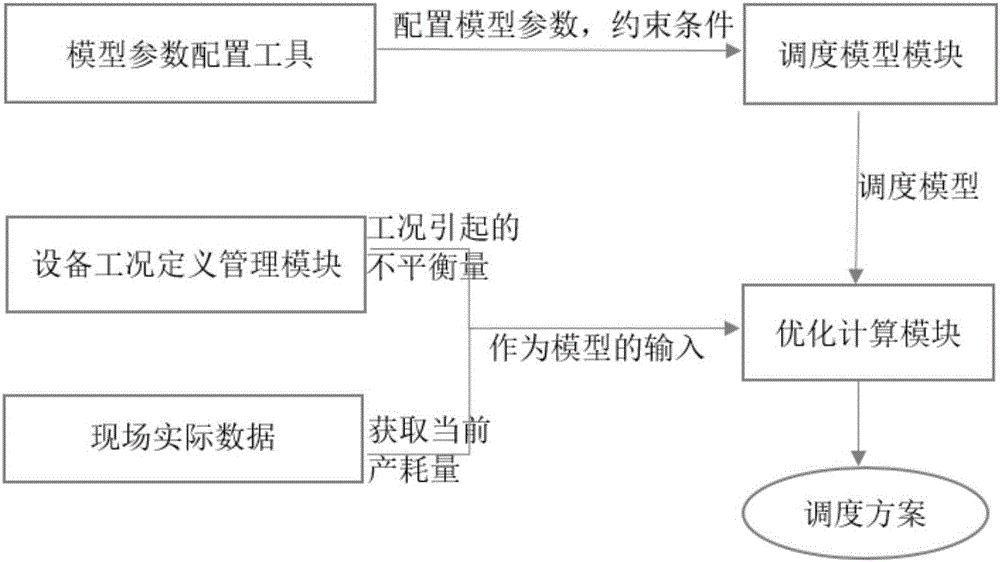

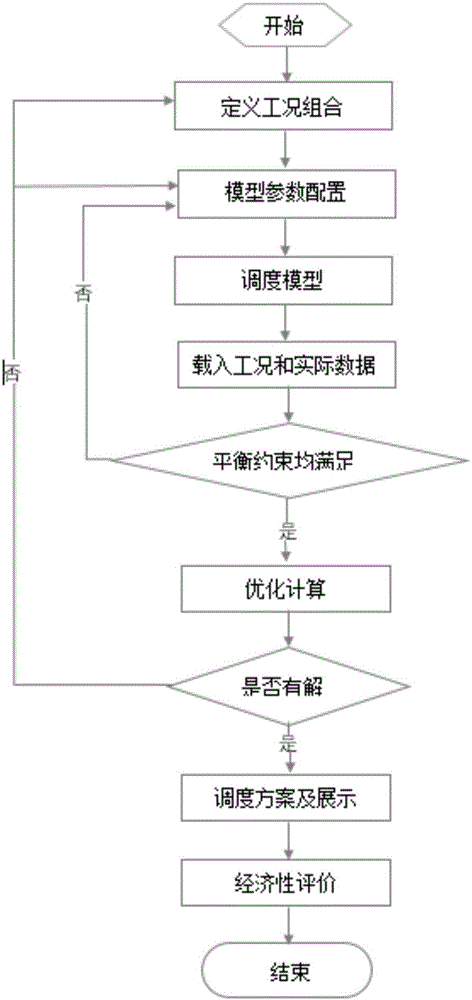

[0082] The present invention is a technical scheme of an energy dispatching system based on a combination of equipment operating conditions, including four modules: an equipment operating condition definition management module, a model parameter configuration module, a scheduling model module, and an optimization calculation module. relationship like figure 1 As shown, the implementation will be executed according to these four modules, and the specific implementation steps are as follows:

[0083] Step 1, the system unbalance obtained from the working condition combination information defined by the equipment working condition definition management module and the current production and consumption obtained from the actual field data are used as the input of the optimization calculation module.

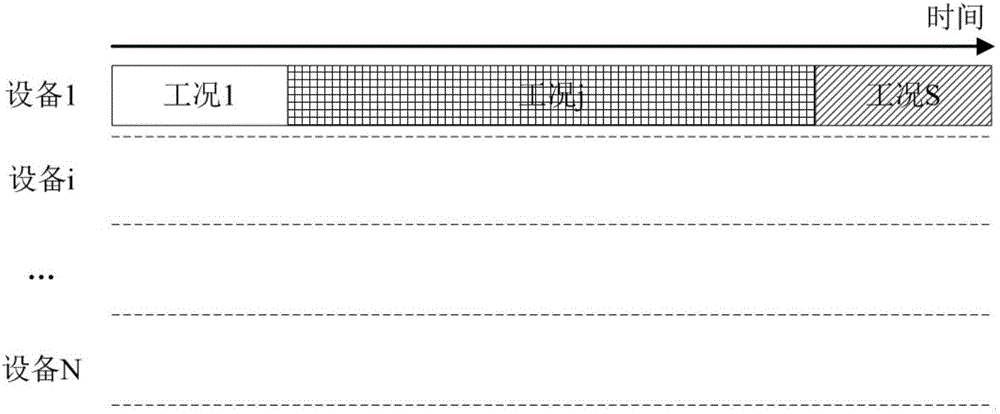

[0084] Firstly, the working condition information is obtained according to the production plan and maintenance plan. Each working condition includes the start and end time of the work...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com