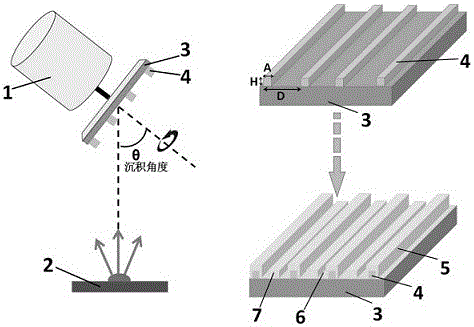

Large-area nanometer slot array and manufacturing method therefor

A nano-gap, large-area technology, applied in the direction of photolithography process exposure devices, microlithography exposure equipment, etc., can solve the problems of complex process, limited nano-gap preparation efficiency, and difficulty in making templates for nano-imprinting, and achieves the cost of the process. wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The following describes in detail the embodiments of the present invention that are used to make large-area nanoslit array structures. To further describe the present invention, it is necessary to point out that the following embodiments are only used for further description of the present invention and cannot be interpreted as protecting the present invention. Limitation of the scope, some non-essential improvements and adjustments to the present invention by those skilled in the art according to the above content of the invention still belong to the protection scope of the present invention.

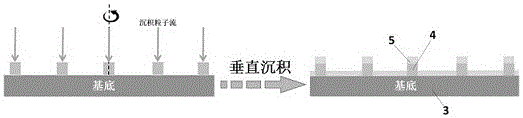

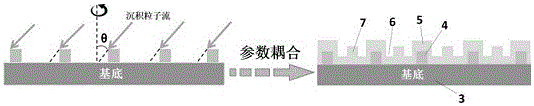

[0019] The steps of interference laser lithography include depositing adhesive on the surface of the silicon wafer, spin-coating photoresist, pre-baking, performing interference exposure in the interference lithography system, and then developing, by controlling the exposure time and development time To adjust the duty cycle of the grating.

[0020] One embodiment of the present...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com