Heat recovery device

A heat energy recovery and heat absorption technology, applied in heat storage equipment, indirect heat exchangers, heat exchanger types, etc., can solve problems such as low thermal conductivity, damage, inability to withstand industrial radiant heat intensity and environmental conditions for long-term operation , to achieve the effect of improving radiant heat absorption efficiency and thermal shock resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] The detailed features and advantages of the present invention are described in detail below in the embodiments, the content of which is sufficient to enable any person skilled in the art to understand the technical content of the present invention and implement it accordingly, and according to the content disclosed in this specification, the scope of claims and the drawings , any person skilled in the art can easily understand the related objects and advantages of the present invention. The following examples further illustrate the concept of the present invention in detail, but do not limit the scope of the present invention in any way. In addition, the proportional relationship of components in the drawings of this application is only for illustrative purposes, and is not intended to limit the scope of the present invention.

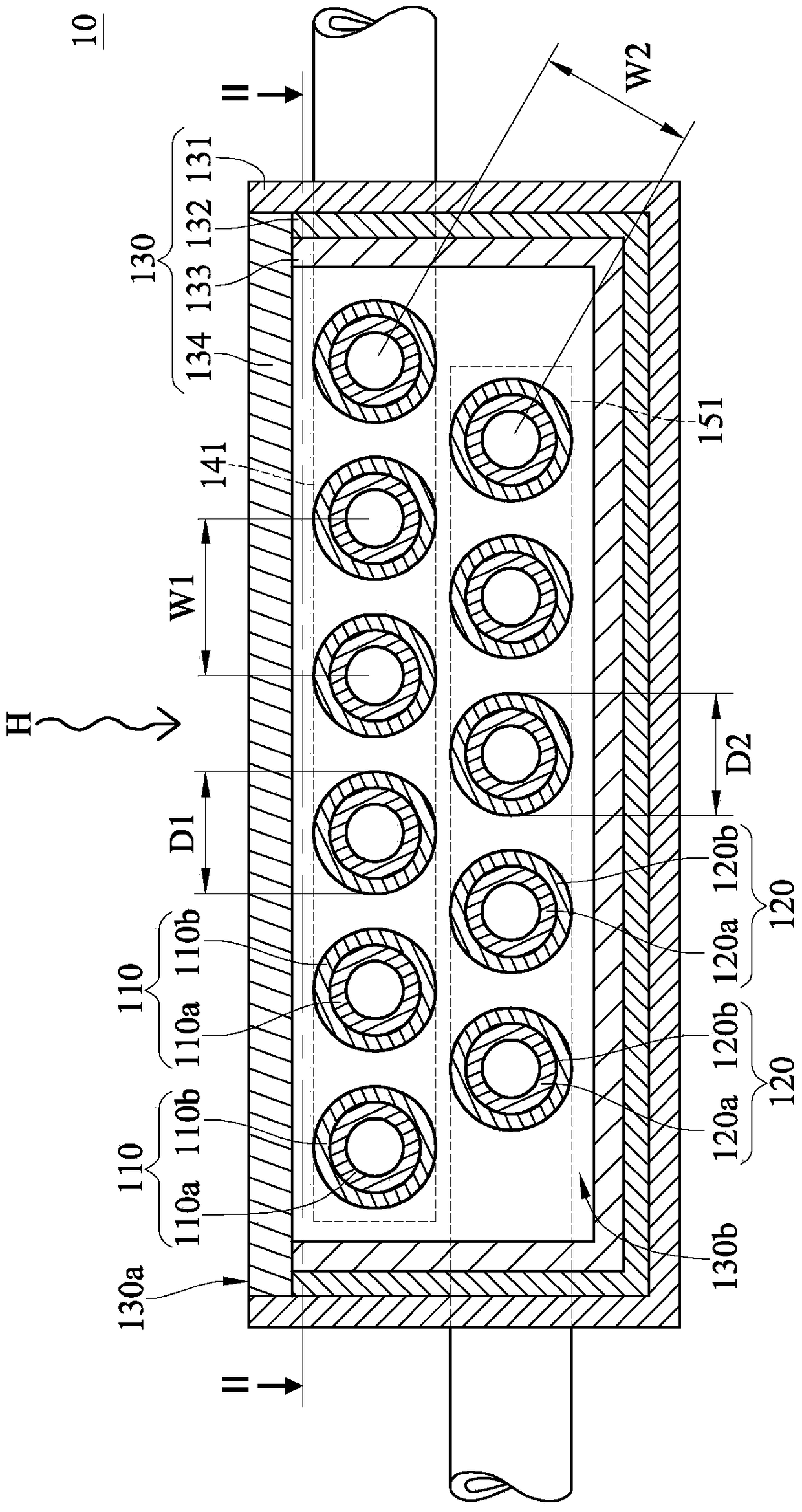

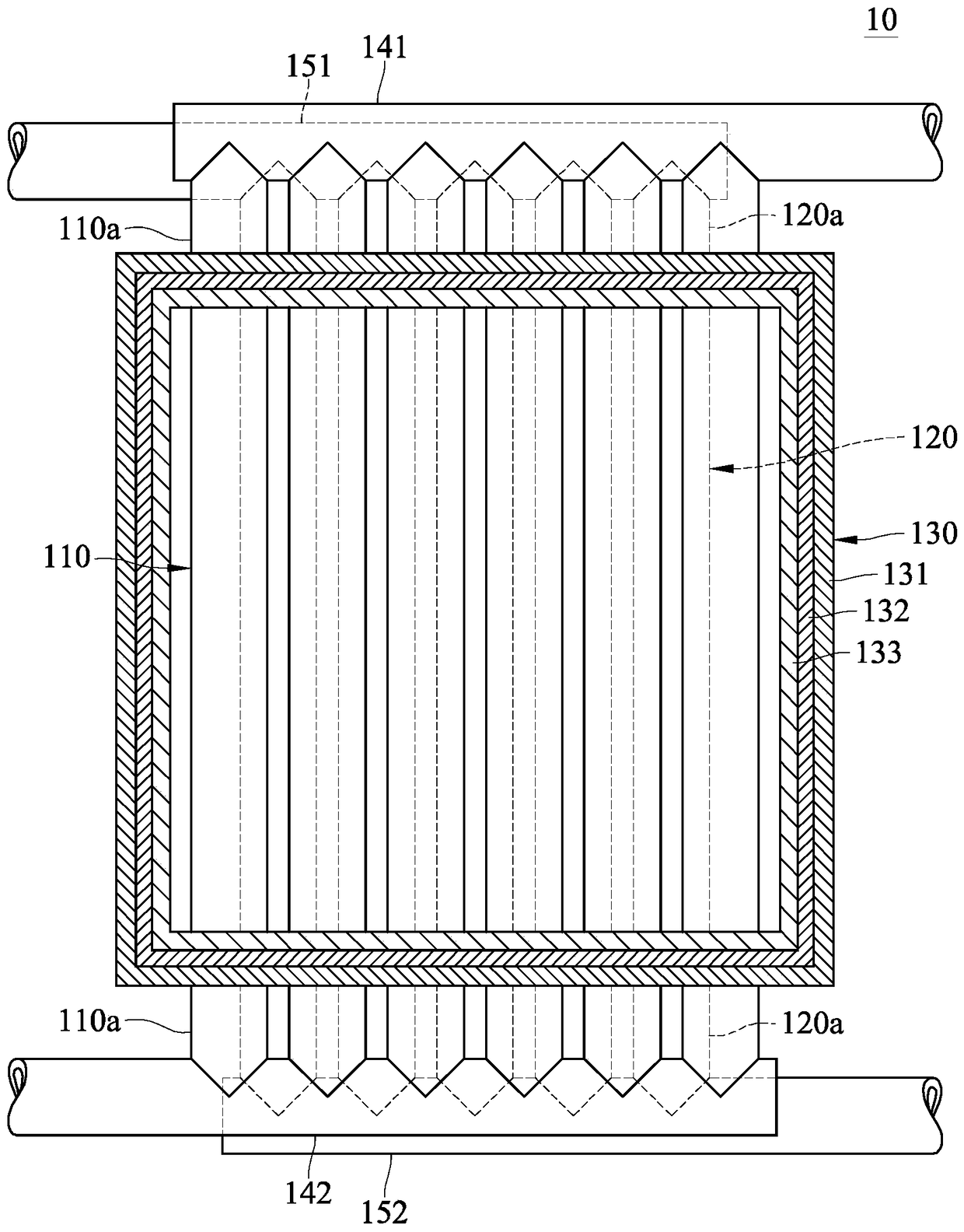

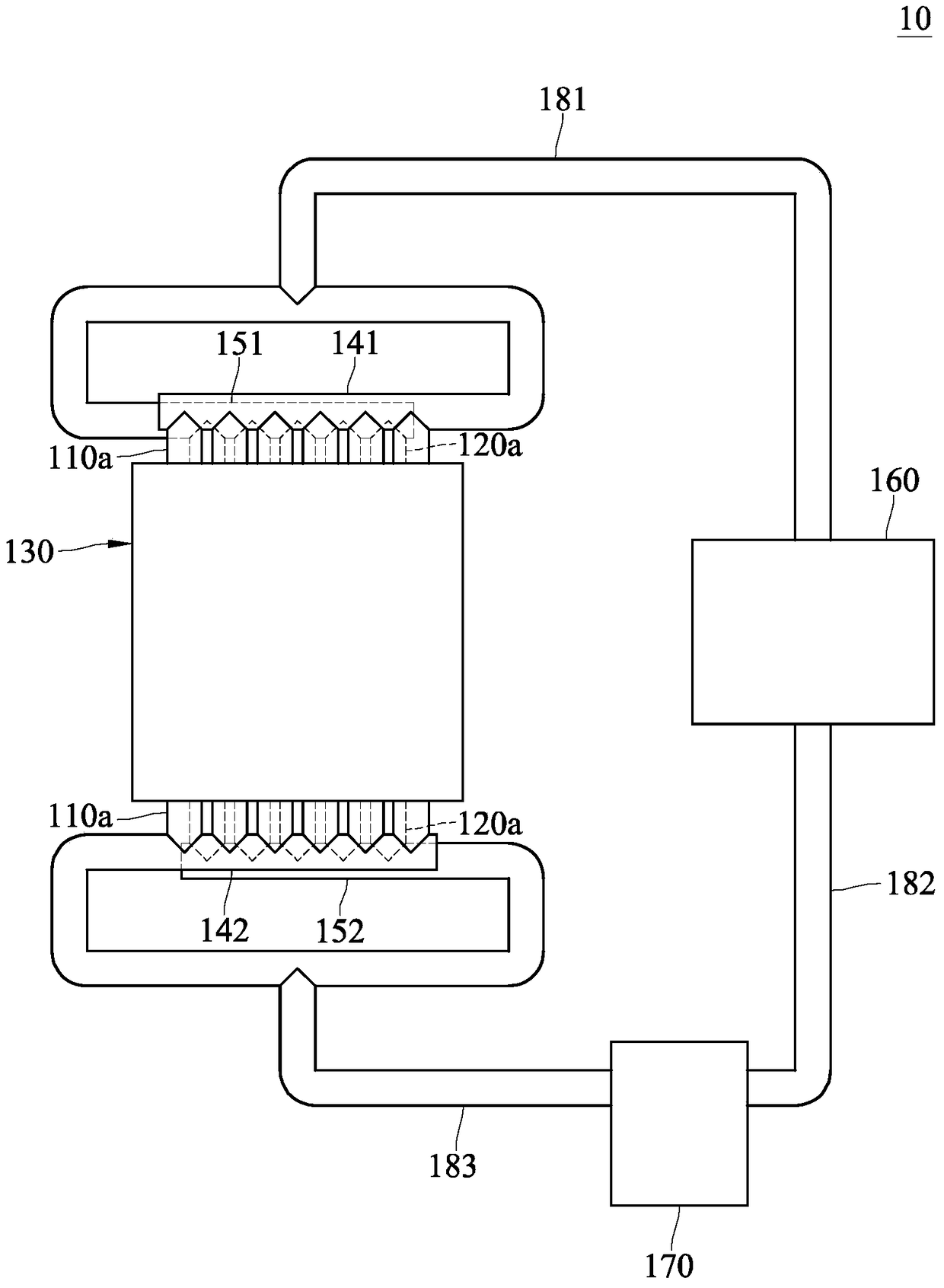

[0064] Please refer to figure 1 , figure 2 and image 3 , figure 1 A partial side cross-sectional schematic diagram of a heat recovery dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com