Fiber-bamboo composite pipe and concrete combination structure

A combined structure and composite pipe technology, applied in the direction of columns, pier columns, pillars, etc., can solve the problems of non-recyclable products and waste, consumption of mineral resources, non-renewable resources, etc., and achieve strong construction operability, good toughness, and low cost. The effect of cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

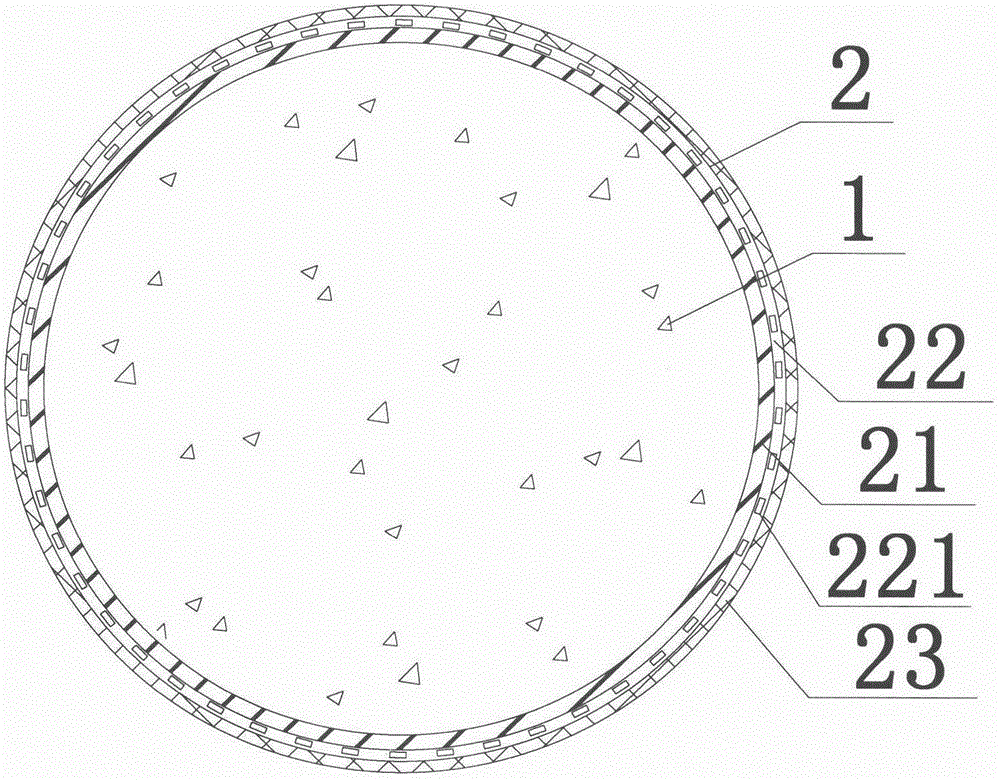

[0033] Such as figure 1 As shown, a cross-sectional schematic diagram of a fiber-bamboo composite tube-concrete composite structure wrapped with a layer of longitudinal bamboo fiber layer, including core concrete 1, fiber-bamboo composite tube 2; wherein, fiber-bamboo composite tube 2 is sequentially from inside to outside Consists of an isolation layer 21, a bamboo reinforcement layer 22, and a fiber reinforcement layer 23; the isolation layer 21 is formed by winding bamboo fiber mats, glass fiber mats or bamboo fiber non-woven fabrics through an adhesive, and the bamboo reinforcement layer 22 in this example is It consists of a longitudinal bamboo fiber layer 221 wrapped around one layer. The fiber reinforced layer 23 is wound on the outer surface of the bamboo reinforced layer 22. The bamboo fiber direction of the longitudinal bamboo fiber layer 221 is along the axial direction of the fiber-bamboo composite pipe 2. The core concrete 1 is filled with Inside the fiber-bamboo ...

Embodiment 2

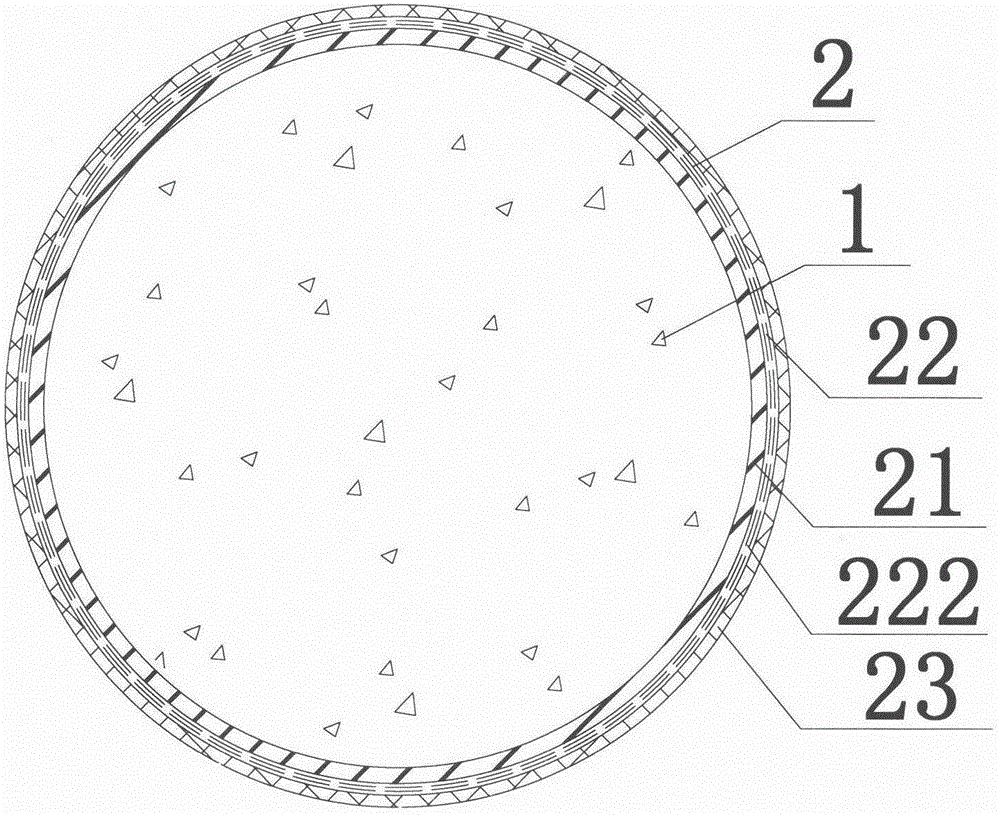

[0035] Such as figure 2 As shown, a cross-sectional schematic diagram of a fiber-bamboo composite tube-concrete composite structure wound with one layer of transverse bamboo fiber layer, including core concrete 1, fiber-bamboo composite tube 2; wherein, fiber-bamboo composite tube 2 is sequentially from inside to outside Consists of an isolation layer 21, a bamboo reinforcement layer 22, and a fiber reinforcement layer 23; the isolation layer 21 is formed by winding bamboo fiber mats, glass fiber mats or bamboo fiber non-woven fabrics through an adhesive, and the bamboo reinforcement layer 22 in this example is It is formed by winding one layer of transverse bamboo fiber layer 222, and the fiber reinforced layer 23 is wound on the outer surface of bamboo reinforced layer 22. The bamboo fiber direction of transverse bamboo fiber layer 222 is along the circumferential direction of fiber-bamboo composite pipe 2, and the core concrete 1 is filled inside the fiber-bamboo composite...

Embodiment 3

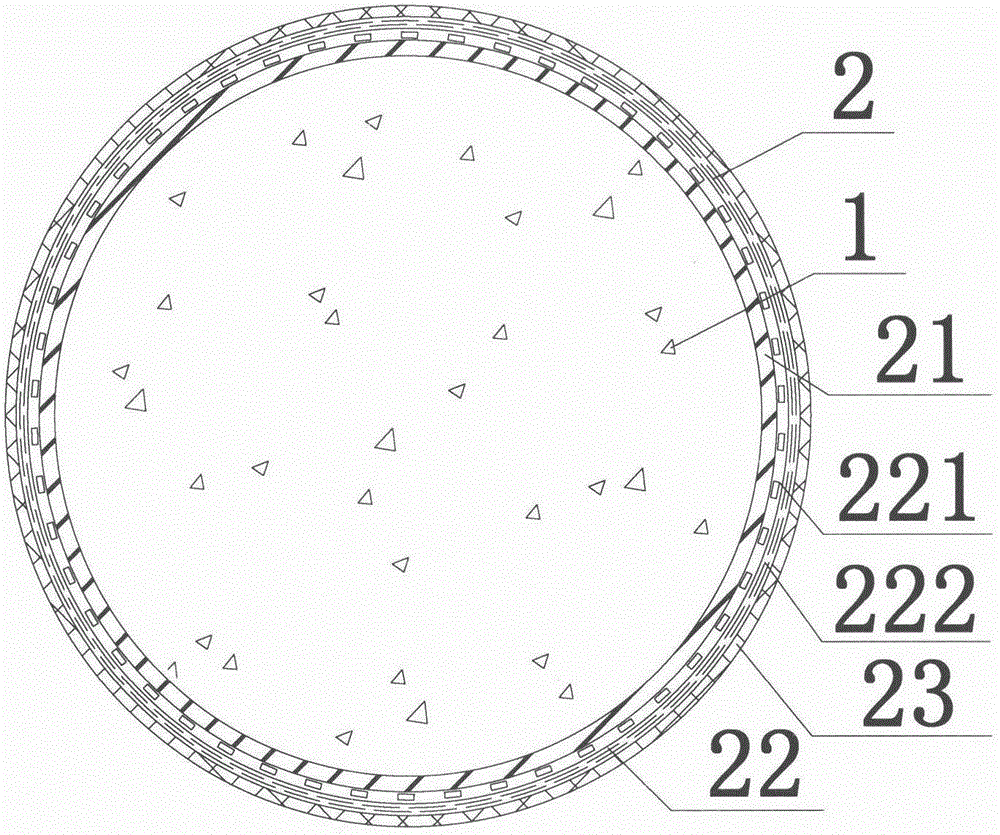

[0037] Such as image 3 As shown, a cross-sectional schematic diagram of a fiber-bamboo composite tube-concrete composite structure wound with one layer of longitudinal bamboo fiber layer and one layer of transverse bamboo fiber layer, including core concrete 1, fiber-bamboo composite tube 2; wherein, fiber-bamboo The composite pipe 2 is composed of an isolation layer 21, a bamboo reinforcement layer 22, and a fiber reinforcement layer 23 from the inside to the outside; the isolation layer 21 is formed by winding bamboo fiber mat, glass fiber mat or bamboo fiber non-woven fabric through an adhesive. The bamboo reinforcement layer 22 is first wound with a layer of longitudinal bamboo fiber layer 221, then a layer of transverse bamboo fiber layer 222 is wound, the fiber reinforcement layer 23 is wound on the outer surface of the bamboo reinforcement layer 22, and the core concrete 1 is filled in the fiber-bamboo composite Inside of tube 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com