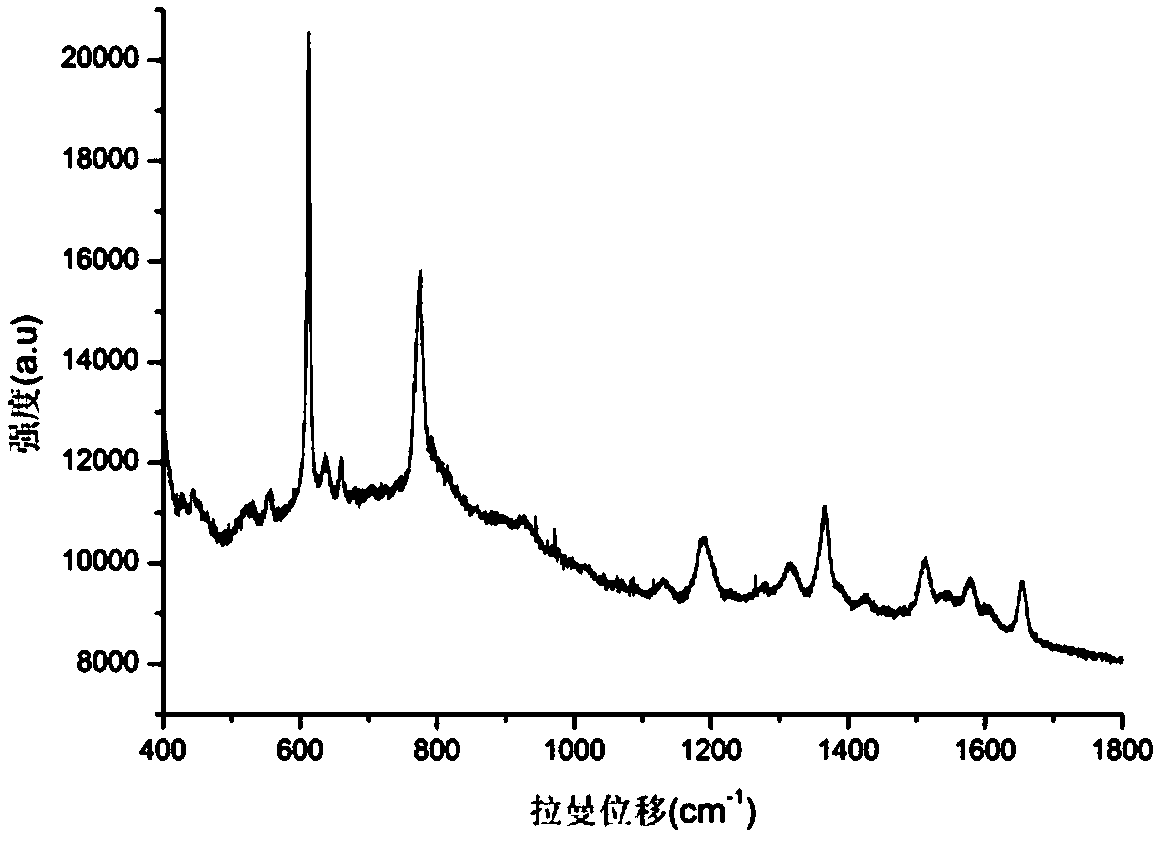

Tungsten oxide substrate with surface-enhanced Raman scattering function and preparation method thereof

A surface-enhanced Raman and tungsten oxide technology is applied in the directions of Raman scattering, anodic oxidation, sputtering coating, etc., which can solve the problems of inconvenient use, complicated SERS substrate preparation process, and high cost, and achieve good repeatability, Enhanced Raman scattering effect, good surface effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] The preparation method of the tungsten oxide substrate with surface-enhanced Raman scattering function of the present invention specifically comprises the following steps:

[0022] The first step is to use anodized aluminum for deoxidation to obtain an aluminum bowl with a micro-nano ordered structure as the substrate material; put the aluminum sheet in acetone and ultrapure water for ultrasonic cleaning, and then perform electrochemical polishing to remove the surface The oxide layer and impurities are removed, and then anodized to produce ordered aluminum oxide on the surface. The generated alumina is put into a deoxidizer for deoxidation treatment to obtain an aluminum bowl with a micro-nano ordered structure.

[0023] In the second step, magnetron sputtering is used to sputter tungsten oxide nano-films on the substrate. The sputtering gas atmosphere is Ar / O2 mixed gas (the gas flow ratio is about 1:1), and the target material can be high-purity tungsten. Target or ...

example

[0032] (1), using secondary or multiple anodizing methods to prepare aluminum bowl substrates with micro-nano structures

[0033] First, pure aluminum sheet (length*width*height: 3cm*3cm*0.05cm, purity 99.99%) is placed in acetone and ultrapure water for ultrasonic cleaning to remove surface organic matter and other impurities. Then put the cleaned aluminum sheet into a polishing solution (volume ratio of ethanol:perchloric acid=4:1) for electrochemical polishing to remove the surface oxide layer and impurities.

[0034] After the polished aluminum sheet is cleaned, it is subjected to secondary or multiple anodic oxidation treatments to produce ordered nano-alumina on the surface. Among them, the aluminum sheet is used as the anode, the molybdenum sheet is used as the cathode, the oxidation solution is 0.5M / L oxalic acid solution, and the time for each oxidation reaction is 2h.

[0035] After the oxidation of the aluminum sheet is completed, the sample is put into the deoxidi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com