Method for producing thin gauge high carbon steel based on esp thin slab continuous casting and rolling process

A thin slab continuous casting, continuous casting and rolling technology, applied in the direction of manufacturing converters, etc., can solve the problems of high energy consumption and high hot rolling cost, and achieve the effects of low temperature, short rolling time and fast solidification speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

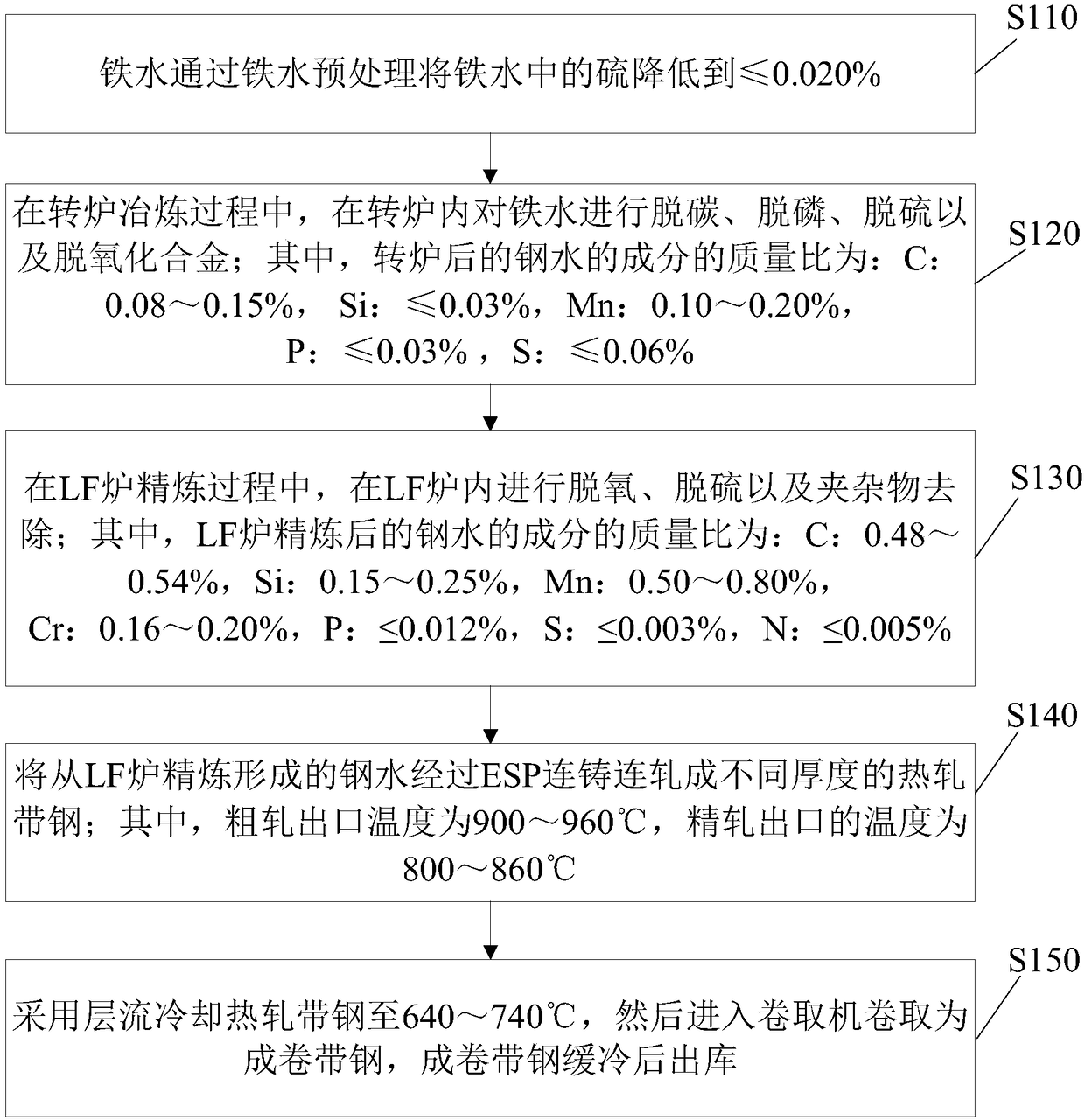

Method used

Image

Examples

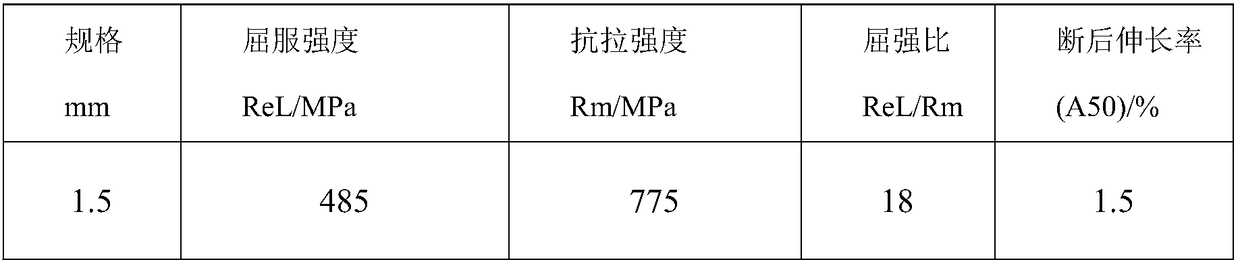

Embodiment 1

[0046] In the embodiment, the process of producing S355J0W steel by the full-endless ESP thin slab continuous casting and rolling process is iron mixing furnace → molten iron pretreatment → BOF → LF → ESP continuous casting and rolling → laminar cooling → coiling → slow cooling → finished product.

[0047] Converter smelting: 300t top-bottom double-blowing converter is used for smelting, and the molten iron is decarburized, dephosphorized and desulfurized in the converter. 0.009%, [S]0.006%, the tapping temperature is 1640°C, the tapping operation is carried out by sliding plate slag control, the amount of slag under the converter is controlled to 40mm, the tapping process adopts argon blowing, deoxidation alloying: add 200Kg of aluminum ingot, carburizer, Ferro-silicon, high-carbon ferrochromium, silicon-manganese alloying, top slag 1 ton.

[0048] LF refining: deoxidation, desulfurization, alloying, inclusion removal in LF furnace, LF refining slag (FeO) 0.55%, binary basic...

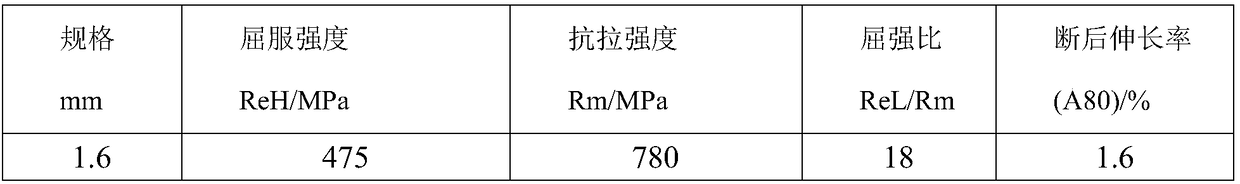

Embodiment 2

[0062] In the embodiment, the process of producing S355J0W steel by the full-endless ESP thin slab continuous casting and rolling process is iron mixing furnace → molten iron pretreatment → BOF → LF → ESP continuous casting and rolling → laminar cooling → coiling → slow cooling → finished product.

[0063] Converter smelting: 300t top-bottom double-blowing converter is used for smelting, and the molten iron is decarburized, dephosphorized and desulfurized in the converter. The end point of the converter is controlled at [C]0.12%, [Si]0.01%, [Mn]0.12%, [P] 0.008%, [S]0.0050%, the tapping temperature is 1650°C, the tapping operation is carried out by sliding plate slag control, the amount of slag lowered by the converter is controlled to 40mm, and the tapping process adopts argon blowing deoxidation alloying: add 230Kg of aluminum ingot, carburant, silicon Iron, high-carbon ferrochromium, silicon-manganese alloy, top slag 1.2 tons.

[0064] LF refining: deoxidation, desulfuriza...

Embodiment 3

[0078] In the embodiment, the process of producing S355J0W steel by the full-endless ESP thin slab continuous casting and rolling process is iron mixing furnace → molten iron pretreatment → BOF → LF → ESP continuous casting and rolling → laminar cooling → coiling → slow cooling → finished product.

[0079] Converter smelting: use 300t top-bottom combined blowing converter to smelt, decarburize, dephosphorize and desulfurize the molten iron in the converter, control the end point of the converter at [C]0.15%, [Si]0.01%, [Mn]0.15%, [P] 0.007%, [S]0.0045%, the tapping temperature is 1650°C, the tapping operation is carried out by sliding plate slag control, the amount of slag in the converter is controlled to 40mm, the tapping process adopts argon blowing, deoxidation and alloying: add 240Kg of aluminum ingots, carburizer, Ferro-silicon, high-carbon ferrochromium, silicon-manganese alloying, top slag 1.5 tons.

[0080] LF refining: deoxidation, desulfurization, alloying, inclusi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com