High-cost-performance high-strength high-conductivity Al-Sc-Zr-Yb alloy and heat treatment technique thereof

A cost-effective and high-strength technology, applied in the field of alloy materials, can solve existing problems, such as reduced electrical conductivity, and achieve the effects of reducing production costs, high cost performance, and improving economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Example 1: Alloy ingots were prepared by graphite crucible smelting and iron mold casting, and the raw materials used were high-purity aluminum and master alloys of Al-2wt%Sc, Al-3wt%Zr, and Al-25wt%Yb. At a melting temperature of 780±10°C, first melt high-purity aluminum ingots, then add Al-Sc, Al-Zr, and Al-Yb master alloys, stir well, keep warm for 15 minutes, and then cast iron molds. The ingot is subjected to homogenization annealing at 640±10° C., and then subjected to cold rolling deformation with a deformation amount of 90%. Five aluminum alloys with different compositions were prepared, and their actual compositions were measured by XRF, as shown in Table 1 below.

[0029] Table 1 Experimental alloy composition

[0030]

Embodiment 2

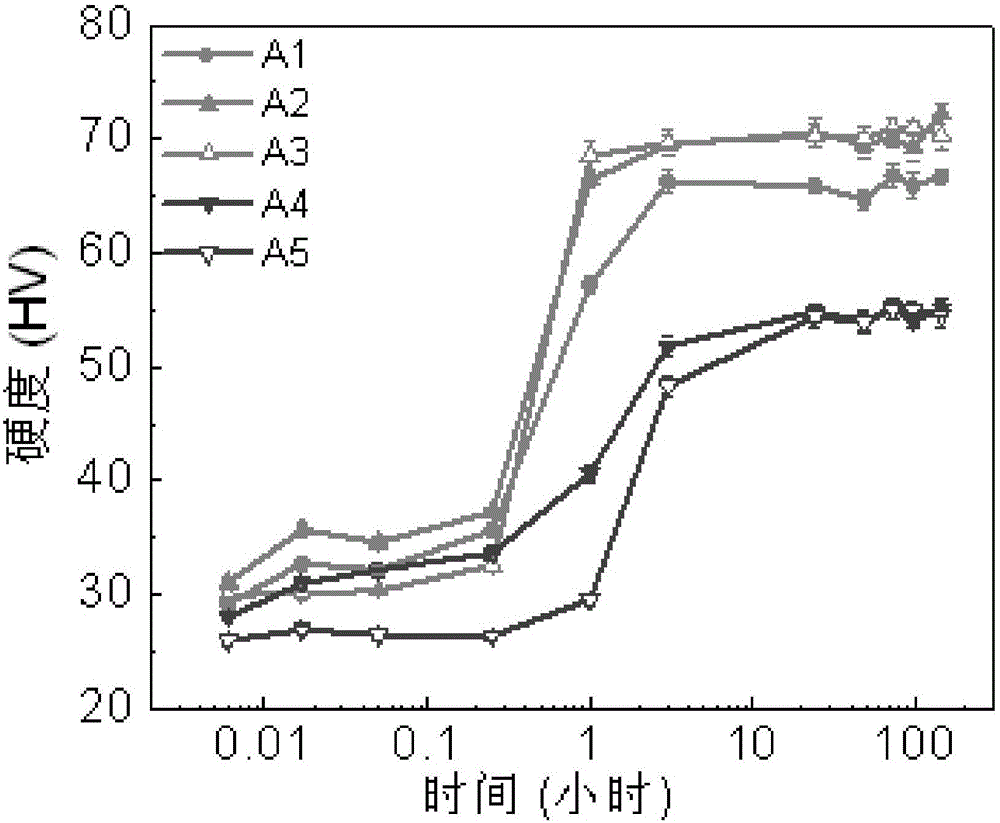

[0031] Embodiment 2: The alloy in Embodiment 1 is subjected to solution treatment at 640±10° C. for 40 to 50 hours, water quenched to room temperature, and then subjected to isothermal aging at 350° C. figure 2 is the hardness curve of the alloy subjected to isothermal aging at 350°C. It can be seen from the figure that in the early stage of aging, the hardness value of the alloy increases continuously with the prolongation of the aging time, and reaches the hardness peak value after 1 hour of aging, and then the hardness value remains basically unchanged as the time prolongs. After aging for 96 hours, the hardness values of A1 and A2 alloys are 66HV and 73HV respectively, which shows that the alloys have a good strengthening effect. Image 6is the electrical conductivity curve of the alloy aged isothermally at 350 °C. It can be seen from the figure that with the prolongation of the aging time, the electrical conductivity shows an overall upward trend. After 96 hours of agi...

Embodiment 3

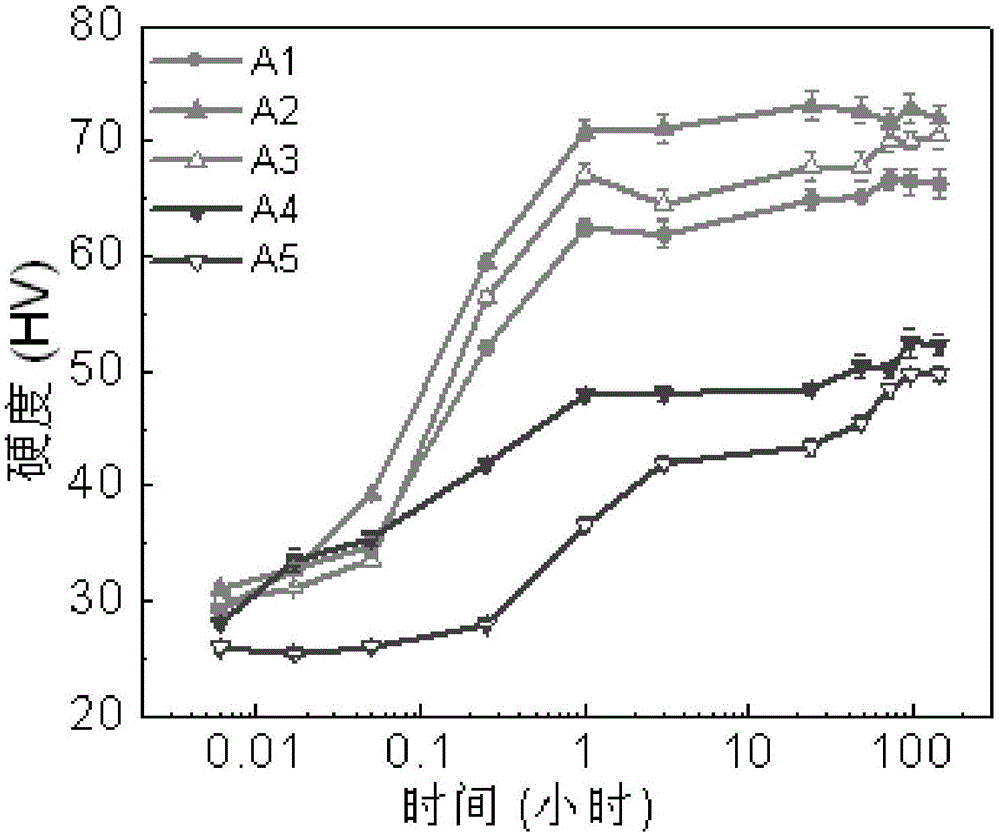

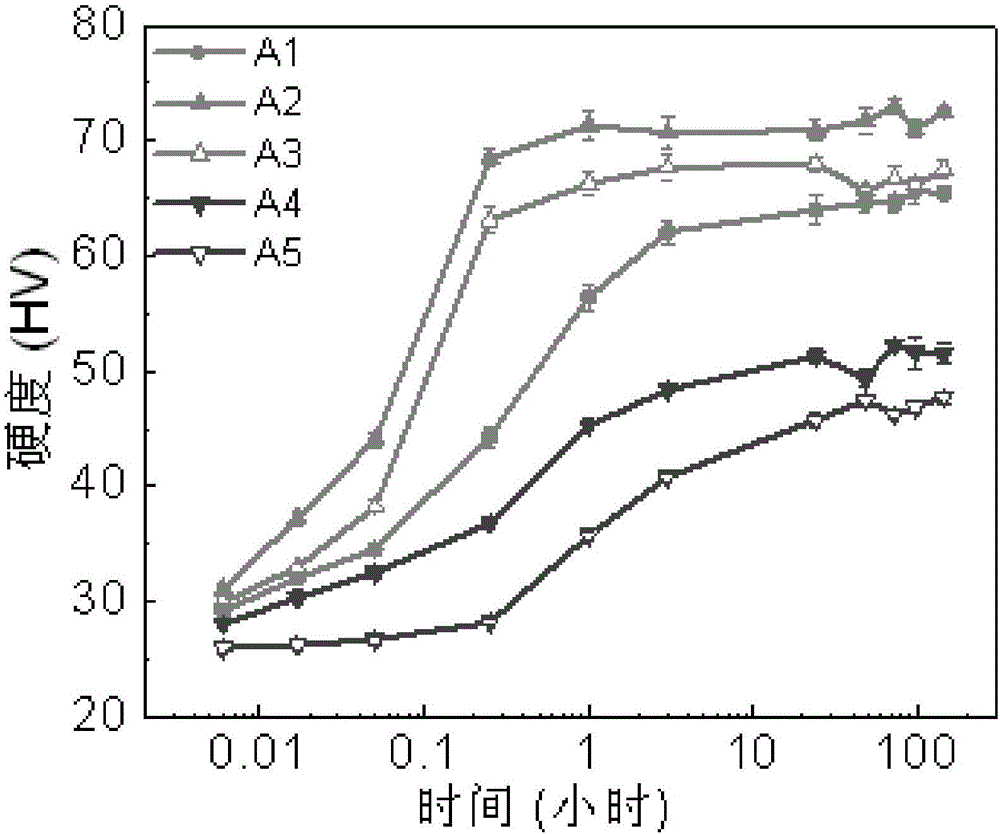

[0032] Embodiment 3: The alloy in Embodiment 1 is subjected to solution treatment at 640±10° C. for 40 to 50 hours, water quenched to room temperature, and then subjected to isothermal aging at 400° C. image 3 , Figure 7 Respectively, the hardness curve and electrical conductivity curve of the alloy aged at 400 °C isothermally. It can be seen from the figure that the changing trends of the hardness curve and the electrical conductivity curve of the alloy are similar to the curves in Example 2. After aging for 96 hours, the hardness values of A1 and A2 alloys are 66HV and 72HV respectively, and the electrical conductivity can reach 60.3%IACS and 60.4%IACS. It can be seen that A1 and A2 alloys have high strength and high conductivity. Although the electrical conductivity of A4 and A5 alloys exceeds 60.0%IACS after aging for 96 hours, their hardness values are only 52HV and 48HV. After aging for 96 hours, the hardness value of A3 alloy is 68HV, and the electrical conducti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com