Soft metal crown and machining method thereof

A processing method and soft technology, applied in metal processing equipment, pharmaceutical formula, dental preparations, etc., can solve problems such as difficult processing, achieve high processing accuracy, reduce investment, and reduce costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

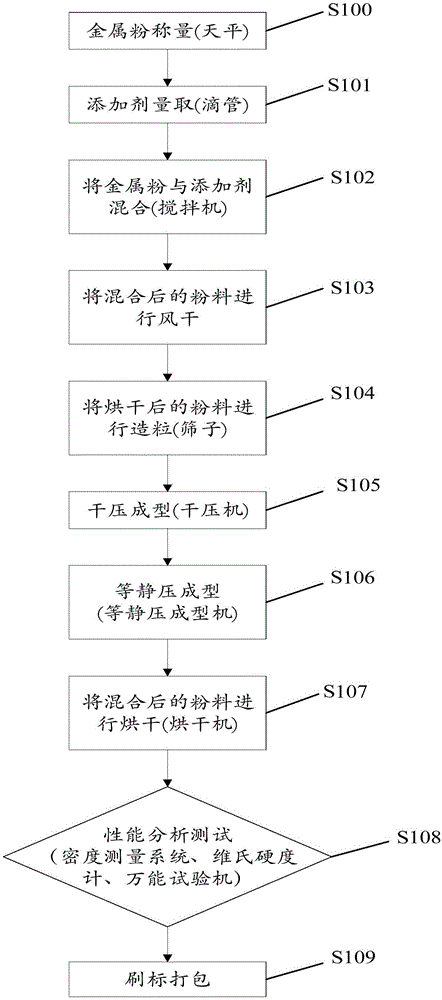

[0046] A processing method for a soft metal crown, the method comprising:

[0047] (1) Calculate the weight of the cobalt-chromium-molybdenum alloy powder required to prepare the soft metal block according to the mold;

[0048] (2) Weigh the cobalt-chromium-molybdenum alloy powder, add the additive SBP styrene-butadiene-styrene to the cobalt-chromium-molybdenum alloy powder, mix and stir evenly, and obtain the mixed powder; the addition amount of SBP is the cobalt-chromium-molybdenum alloy powder 1% of powder weight;

[0049] The cobalt-chromium-molybdenum alloy powder comprises the following components by weight percentage:

[0050] Cr content is 28%, Mo content is 6.0%, O content is 0.05%, and the rest is Co content;

[0051] The particle size distribution of cobalt-chromium-molybdenum alloy powder is 400-500 mesh, accounting for 83%;

[0052] (3) Air-dry the mixed powder again, air-dry at room temperature 25°C for 30 minutes, pass the air-dried powder through a 400-mesh ...

Embodiment 2

[0056] A processing method for a soft metal crown, the method comprising:

[0057] (1) Calculate the weight of the cobalt-chromium-molybdenum alloy powder required to prepare the soft metal block according to the mold;

[0058] (2) Weigh the cobalt-chromium-molybdenum alloy powder, add additive SD-2X to the cobalt-chromium-molybdenum alloy powder and mix and stir evenly to obtain mixed powder; the addition of SD-2X is 2.5% of the weight of the cobalt-chromium-molybdenum alloy powder; SD-2X was purchased from Tengfei Cemented Carbide Forming Agent Co., Ltd., Hetang District, Zhuzhou City;

[0059] The cobalt-chromium-molybdenum alloy powder comprises the following components by weight percentage:

[0060] Cr content is 27.0%, Mo content is 6.5%, O content is 0.03, and the rest is Co content;

[0061] The particle size distribution of cobalt-chromium-molybdenum alloy powder is 400-500 mesh, accounting for 80%;

[0062] (3) Air-dry the mixed powder again, air-dry at room tempera...

Embodiment 3

[0066] A processing method for a soft metal crown, the method comprising:

[0067] (1) Calculate the weight of the cobalt-chromium-molybdenum alloy powder required to prepare the soft metal block according to the mold;

[0068] (2) Weigh the cobalt-chromium-molybdenum alloy powder, add additive PEG2000 to the cobalt-chromium-molybdenum alloy powder, mix and stir evenly, and obtain mixed powder; the addition amount of PEG2000 is 0.5% of the weight of the cobalt-chromium-molybdenum alloy powder;

[0069] The cobalt-chromium-molybdenum alloy powder comprises the following components by weight percentage:

[0070] Cr content is 29.0%, Mo content is 5.5%, O content is 0.04, and the rest is Co content;

[0071] The particle size distribution of cobalt-chromium-molybdenum alloy powder is 400-500 mesh, accounting for 85%;

[0072] (3) Air-dry the mixed powder again, air-dry at room temperature 20°C for 40 minutes, pass the air-dried powder through a 500-mesh sieve, and then granulat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com