Method for copper smelting white smoke dust arsenic removal

A white smoke, copper smelting technology, applied in the direction of improving the process efficiency, can solve the problems such as the inability to fully utilize the heat of chemical reaction as energy, the consumption of fossil fuel or electric energy, and the low concentration of the output flue gas, and achieve strong acidity. , The equipment has large production capacity and good effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

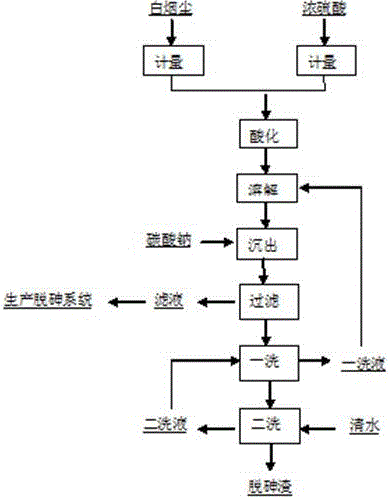

[0030] A method for removing arsenic from copper smelting white fume described in this embodiment specifically includes the following steps:

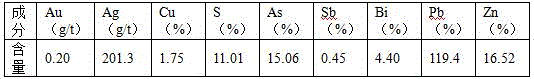

[0031] (1) Acidification: The main components of white soot are shown in Table 1.1. Take 1 ton of the white soot and put it into an acidification tank with a seal and a stirring device. After calculation, the theoretical amount of acid used to convert arsenic into arsenic acid It is 301kg, calculated by 1.1 times, add 331kg of 98% sulfuric acid, start the mixer after adding acid, and let stand for 5 hours after homogenization;

[0032] Table 1.1 Main components of white soot (mass percentage %)

[0033]

[0034] (2) Dissolution: After the acidification in step (1), add 4 tons of water, operate at room temperature, and dissolve under stirring for 1.0 hour, and the stirring speed can be as long as the solid has relative flow;

[0035] (3) Re-sedimentation: Step (2) After the dissolution, add solid sodium carbonate to adjust the pH val...

Embodiment 2

[0038] A method for removing arsenic from copper smelting white fume described in this embodiment specifically includes the following steps:

[0039] (1) Acidification: The main components of white soot are shown in Table 2.1. Take 1 ton of the white soot and put it into an acidification tank with a seal and a stirring device. After calculation, the theoretical amount of acid used to convert arsenic into arsenic acid It is 284kg, calculated by 1.2 times, add 341kg of 98% sulfuric acid, start the mixer after adding acid, and leave standstill for 4 hours after homogenization;

[0040] Table 2.1 Main components of white soot (mass percentage %)

[0041]

[0042] (2) Dissolution: After the acidification of step (1), add 5 tons of water for the first washing solution in step (4) of Example 1, operate at room temperature, and dissolve for 1.5 hours under stirring. The stirring speed is relative to the solid. Just flow;

[0043] (3) Re-sedimentation: after the dissolution in ste...

Embodiment 3

[0045] A method for removing arsenic from copper smelting white fume described in this embodiment specifically includes the following steps:

[0046] (1) Acidification: The main components of white soot are shown in Table 3.1. Take 1 ton of the white soot and put it into an acidification tank with a seal and a stirring device. After calculation, the theoretical amount of acid used to convert arsenic into arsenic acid It is 269kg, calculated by 1.15 times, add 310kg of 98% sulfuric acid, start the stirrer after adding acid, leave standstill for 4.5 hours after homogenization;

[0047] Table 3.1 Main components of white soot (mass percentage %)

[0048]

[0049] (2) Dissolution: After the acidification in step (1), add 4.5 tons of water for the first washing solution in step (4) of Example 2, operate at room temperature, and dissolve for 1 hour under stirring. The stirring speed is relative to the solid. Just flow;

[0050] (3) Re-sedimentation: Step (2) After the dissoluti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com