Method and system for improving metallurgical performance of sulfuric-acid residue pellets

A technology for sulfuric acid slag pellets and sulfuric acid slag, which is applied in the field of improving the metallurgical properties of sulfuric acid slag pellets, can solve the problems of no preventive measures for the expansion problem, no mention of the reduction expansion inhibition method of the sulfuric acid slag pellets, etc. Improved expansion rate index, less impurities, and remarkable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

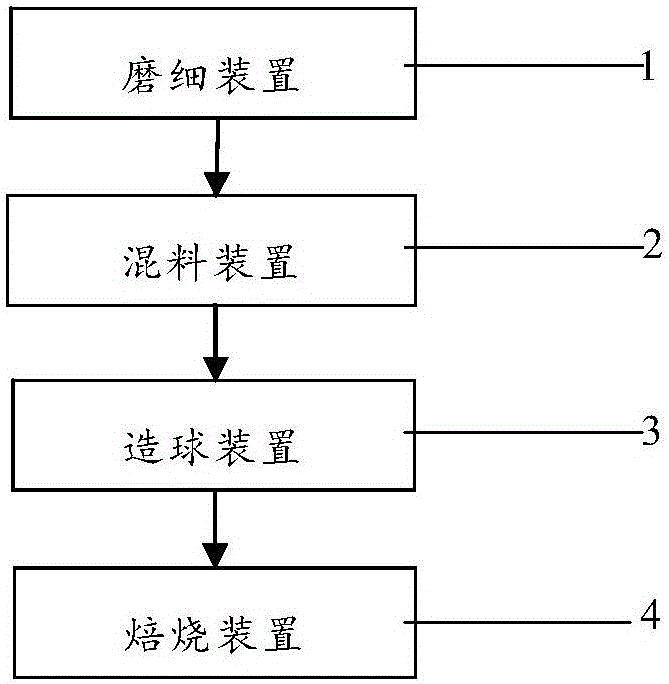

Image

Examples

Embodiment 1

[0044] (1) Grinding the sulfuric acid slag finely to obtain the sulfuric acid slag powder, the ratio of which the particle size is required to be less than 0.074mm is between 50% and 70%;

[0045] (2) mixing the sulfuric acid slag powder and bentonite to obtain a mixture; the specific proportioning is, sulfuric acid slag powder 97kg, bentonite 3kg;

[0046] (3) The mixture is made into green balls on a pelletizing machine (disc pelletizing machine), and the green balls are balls with a diameter of 8-15mm; wherein, boric acid aqueous solution is added during the pelletizing process as pelletizing pellets With water, the concentration of boric acid aqueous solution is 0.5% (mass percentage); the addition point of boric acid is the water addition point of the pelletizer, first add boric acid to the water adding tank for adding water to raw balls, and prepare boric acid aqueous solution with required concentration with boric acid and water , add water to the raw ball along with th...

Embodiment 2

[0050] (1) Grinding the sulfuric acid slag finely to obtain the sulfuric acid slag powder, the ratio of which the particle size is required to be less than 0.074mm is between 50% and 70%;

[0051] (2) mixing the sulfuric acid slag powder and bentonite to obtain a mixture; the specific proportioning is, sulfuric acid slag powder 99kg, bentonite 1kg;

[0052] (3) The mixture is made into green balls on a pelletizing machine (cylindrical pelletizing machine), and the green balls are balls with a diameter of 8-15mm; wherein, boric acid aqueous solution is added during the pelletizing process as pelletizing pellets With water, the concentration of boric acid aqueous solution is 1% (mass percentage); the addition point of boric acid is the water addition point of the pelletizer, first add boric acid to the water adding tank for adding water to raw balls, and prepare boric acid and water to obtain the required concentration of boric acid aqueous solution , add water to the raw ball a...

Embodiment 3

[0056] (1) Grinding the sulfuric acid slag finely to obtain the sulfuric acid slag powder, the ratio of which the particle size is required to be less than 0.074mm is between 50% and 70%;

[0057] (2) mixing the sulfuric acid slag powder and bentonite to obtain a mixture; the specific proportioning is, sulfuric acid slag powder 98kg, bentonite 2kg;

[0058] (3) The mixture is made into green balls on a pelletizing machine (disc pelletizing machine), and the green balls are balls with a diameter of 8-15mm; wherein, boric acid aqueous solution is added during the pelletizing process as pelletizing pellets With water, the concentration of boric acid aqueous solution is 1.5% (mass percentage); the addition point of boric acid is the water addition point of the pelletizer, first add boric acid to the water adding tank for adding water to raw balls, and prepare boric acid aqueous solution with required concentration with boric acid and water , add water to the raw ball along with th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com