Method for extracting shale oil gas through in-situ catalytic oxidation of oil shale

An in-situ catalysis and shale oil and gas technology, which is applied in the petroleum industry, earth drilling, and hydrocarbon oil treatment, can solve the problems of slow oil shale cracking reaction, low energy utilization rate, and large floor area, etc. Porosity, improved energy efficiency, effect of increased porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

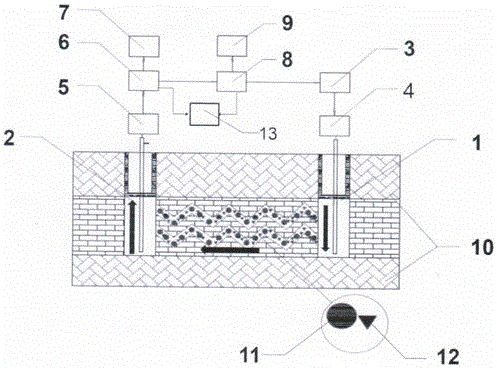

[0037] see figure 1 Shown, be the first embodiment of the present invention, its pattern of well arrangement is double well form, and its specific implementation is as follows:

[0038] The burial depth of oil shale in a certain place is 65m-75m, with an average oil content of 6%, water content of 4%, and fixed carbon of 21%. The roof and floor are both tight shale. Concrete implementation steps are as follows:

[0039] (1) drilling and completion

[0040] a. According to the distribution and trend of oil shale, use advanced drilling technology to drill at least one gas injection well 1 and production well 2 to the depth of the target oil shale layer to a depth of 77m, and the gas injection well 1 and production well 2 adopt the same well depth structure.

[0041] b. Establish a fracturing chamber in the heat injection well 1, and perforate in the direction of the production well 2 at intervals of one meter in the 66m-74m section of the casing of the heat injection well 1, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com