PC composite based on basalt fiber reinforcement and preparation method thereof

A technology of basalt fiber and composite materials, which is applied in the field of basalt fiber-reinforced PC composite materials and its preparation, can solve the problems of inability to meet the strength requirements of parts, material performance degradation, and easy damage, and achieve excellent performance and tensile strength. The effect of highlighting the intensity and improving the descriptive

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

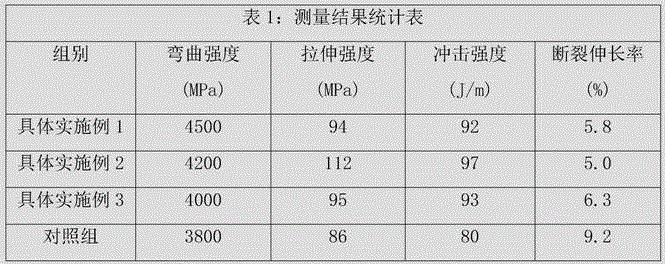

Examples

specific Embodiment 1

[0025] Based on basalt fiber reinforced PC composite material, including the following components in parts by weight, 30 parts of PC; 30 parts of basalt fiber; 5 parts of kaolin; 12 parts of acrylic fiber; 10 parts of polypropylene; 5 parts of toughening agent; 1.5 parts of lubricant parts; 1.5 parts of coupling agent; 5 parts of compatibilizer.

[0026] The preparation method based on the PC composite material reinforced by basalt fiber comprises the following steps, a. get PC, basalt fiber, kaolin, acrylic fiber, polypropylene, toughening agent, lubricant, coupling agent, compatibilizer of formula quantity, Mix evenly; b. import each component in step a into a screw extruder and extrude to obtain a strip; c. carry out water cooling and air-drying treatment on the strip; d. take the cooled and dried strip in step c and cut grain.

[0027] In step b, the extrusion temperature of the screw extruder is 220° C., and the screw speed is 170 r / m.

specific Embodiment 2

[0029] Based on basalt fiber reinforced PC composite material, including the following components in parts by weight, 35 parts of PC; 20 parts of basalt fiber; 5 parts of kaolin; 12 parts of acrylic fiber; 15 parts of polypropylene; 5 parts of toughening agent; 1.5 parts of lubricant parts; 1.5 parts of coupling agent; 5 parts of compatibilizer.

[0030] The preparation method based on the PC composite material reinforced by basalt fiber comprises the following steps, a. get PC, basalt fiber, kaolin, acrylic fiber, polypropylene, toughening agent, lubricant, coupling agent, compatibilizer of formula quantity, Mix evenly; b. import each component in step a into a screw extruder and extrude to obtain a strip; c. carry out water cooling and air-drying treatment on the strip; d. take the cooled and dried strip in step c and cut grain.

[0031] In step b, the extrusion temperature of the screw extruder is 220° C., and the screw speed is 170 r / m.

specific Embodiment 3

[0033] The PC composite material reinforced based on basalt fiber comprises the following components in parts by weight, 40 parts of PC; 10 parts of basalt fiber; 5 parts of kaolin; 12 parts of acrylic fiber; 20 parts of polypropylene; 5 parts of toughening agent; 1.5 parts of lubricant parts; 1.5 parts of coupling agent; 5 parts of compatibilizer.

[0034] The preparation method based on the PC composite material reinforced by basalt fiber comprises the following steps, a. get PC, basalt fiber, kaolin, acrylic fiber, polypropylene, toughening agent, lubricant, coupling agent, compatibilizer of formula quantity, Mix evenly; b. import each component in the step a into a screw extruder and extrude to obtain a strip; c. carry out water cooling and air-drying to the strip; d. take the cooled and dried strip in step c and cut grain.

[0035] In step b, the extrusion temperature of the screw extruder is 220° C., and the screw speed is 170 r / m.

[0036] Control group:

[0037] PC ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com