Polyphosphoester containing fluorine and silicon as well as preparation method and application thereof

A technology of silicon polyphosphate and cyclic phosphate, which is applied in the field of organic flame retardant materials, can solve the problems of poor compatibility, inability to expand the application fields of flame retardants and polymer materials, and single function, so as to reduce surface energy, Improve the protective effect and enhance the effect of the carbon layer structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] (1) Add 8.00g (9.14mmol) aminopropyl cage polysilsesquioxane (NH 2 -POSS), 1.12g (11.06mmol) triethylamine and 25mL dichloromethane, then slowly drop 1.96g (13.75mmol) 2-chloro-2-oxo-1,3,2-dioxaphosphine Pentane, reacted at room temperature for 8 hours; then filtered to remove triethylamine hydrochloride, repeatedly quenched the obtained filtrate with water, took the organic phase and dried it with anhydrous magnesium sulfate, filtered it with suction, and rotary evaporated to remove the solvent to obtain a silicon-containing cyclic phosphate monomer.

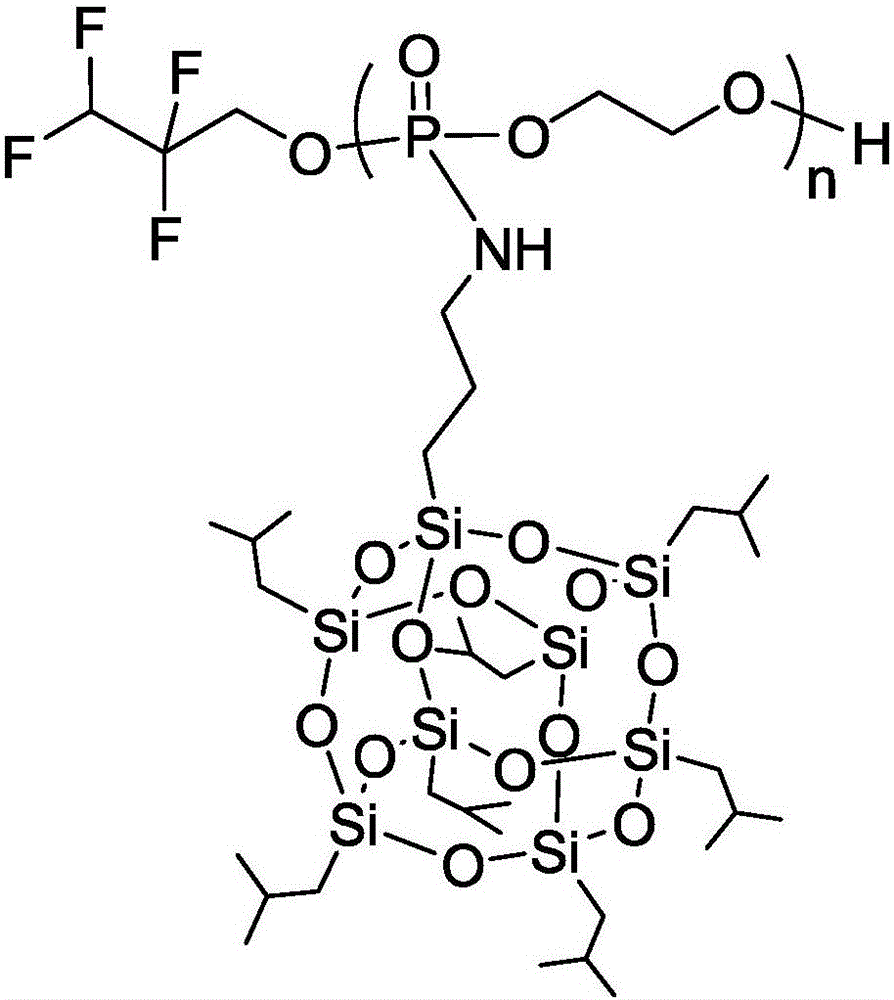

[0034] (2) Take 6.08g (6.20mmol) of the silicon-containing cyclic phosphate monomer obtained in step (1) in a single-mouth bottle, add 13.60mg (0.10mmol) tetrafluoropropanol, 20.00mg (0.04mmol) isooctanoic acid sulfide Tin and 10mL tetrahydrofuran, heated up to 80°C, reacted for 6h, after the reaction was completed, the solvent was spin-dried to obtain fluorine-containing silicon polyphosphate (such as figure 1 shown)....

Embodiment 2

[0039] (1) The synthesis of silicon-containing cyclic phosphate monomer is the same as in Example 1.

[0040] (2) The synthesis of fluorine-containing silicon polyphosphate is the same as in Example 1.

[0041] (3) Weigh 20g of epoxy resin prepolymer and heat up to 90°C, add 6.26g of fluorine-containing silicon polyphosphate obtained in step (2), stir until the mixture is uniform and transparent, add 5.05g of DDM until completely dissolved, Pour it into an aluminum mold, cure at 120°C for 4 hours, at 140°C for 2 hours, and at 180°C for 2 hours to obtain a flame-retardant epoxy resin.

[0042] According to GB / T 2406-2009, the oxygen index of the above-mentioned flame-retardant epoxy resin is 33.1%.

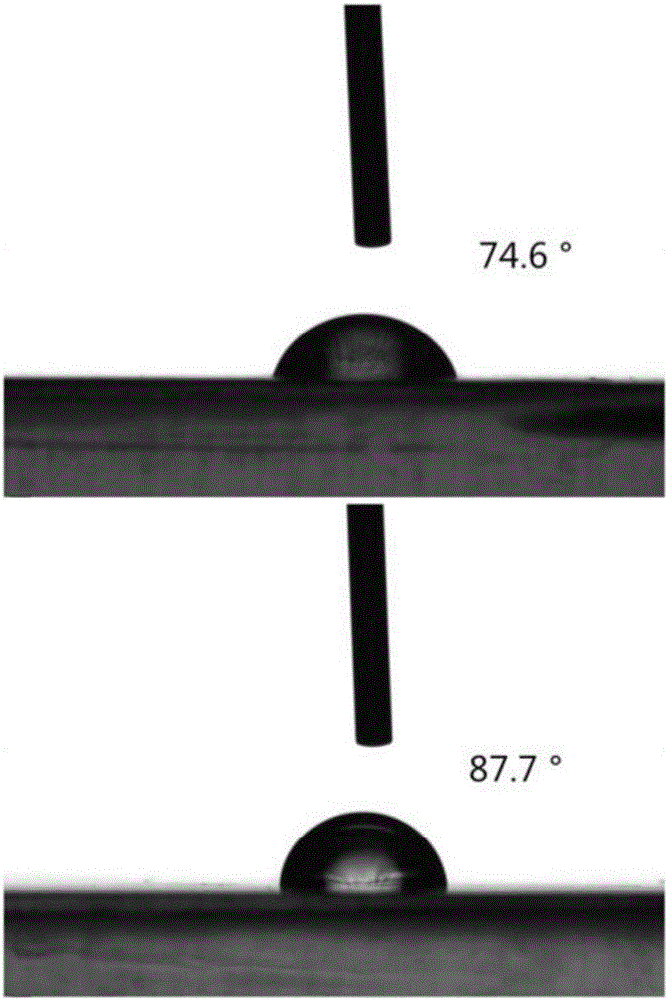

[0043] According to GB / T 30693-2014, the water contact angle of the above-mentioned flame-retardant epoxy resin is 90.5°.

Embodiment 3

[0045] (1) The preparation of the silicon-containing cyclic phosphate monomer is the same as in Example 1.

[0046] (2) Take 6.08g (6.20mmol) of the silicon-containing cyclic phosphate monomer obtained in step (1) in a one-mouth bottle, add 24.41mg (0.10mmol) of 3,5-bis(trifluoromethyl)benzyl alcohol, 20.00 mg (0.04 mmol) of stannous isooctanoate and 10 mL of tetrahydrofuran were heated up to 80°C and reacted for 6 hours. After the reaction, the solvent was spin-dried to obtain fluorine-containing silicon polyphosphate.

[0047] (3) Weigh 20g of epoxy resin prepolymer and raise the temperature to 90°C, add 2.78g of fluorine-containing silicon polyphosphate obtained in step (2), stir until it is uniform and transparent, then add 5.05g of DDM until completely dissolved, Then pour it into an aluminum mold, cure at 120°C for 4 hours, at 140°C for 2 hours, and at 180°C for 2 hours to obtain a flame-retardant epoxy resin.

[0048] According to GB / T 2406-2009, the oxygen index of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| limiting oxygen index | aaaaa | aaaaa |

| water contact angle | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com