Magnetic composite gel microspheres and preparation method thereof

A composite gel and composite microsphere technology, applied in chemical instruments and methods, drilling compositions and other directions, can solve the problems of reduced water absorption, unstable structure, loss of blocking and regulating effect, etc., and achieves simple steps and easy implementation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0049] The present invention provides a method for preparing magnetic composite gel microspheres described in the above scheme, comprising the following steps:

[0050] (1) the modified nano-Fe 3 o 4 Dispersed in organic solvents to obtain modified nano-Fe 3 o 4 the dispersion liquid;

[0051] (2) the modified nano-Fe 3 o 4 The dispersion liquid and the emulsifier are mixed and emulsified to obtain the modified nano-Fe 3 o 4 Lotion;

[0052] (3) the modified nano-Fe 3 o 4 Emulsion and acrylic acid and polyacrylamide carry out the first crosslinking reaction under the condition of sodium hydroxide, crosslinking agent and initiator, obtain acrylic acid-acrylamide copolymer / Fe 3 o 4 Composite microspheres;

[0053] (4) the acrylic acid-acrylamide copolymer / Fe 3 o 4 Composite microspheres dispersed in organic solvents to obtain acrylic acid-acrylamide copolymer / Fe 3 o 4 Composite gel microsphere dispersion;

[0054] (5) the acrylic acid-acrylamide copolymer / Fe 3 ...

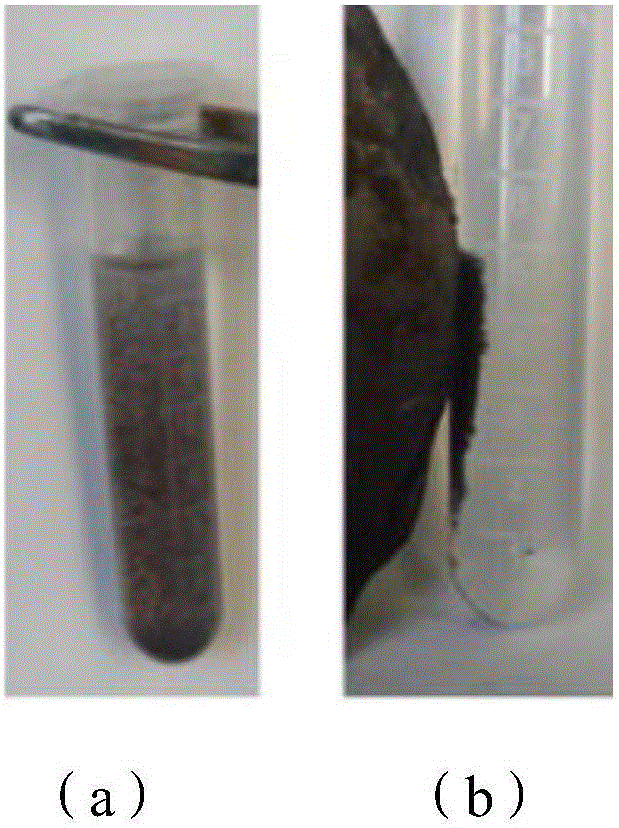

Embodiment 1

[0078] a) Preparation of nano ferric oxide: under a nitrogen atmosphere, add iron oxide and ferrous oxide to a three-necked flask equipped with deionized water at 50°C to control Fe 3+ :Fe 2+ =3:2, after mechanically stirring and dissolving evenly, add 25% ammonia water dropwise according to the speed of 5 seconds / drop to adjust the pH value to 11; stir and react for 4h, use magnetic tilting method (add acetone or ethanol to the beaker, Put a magnet on its bottom, pour out the upper layer solution after it is flocculated) and treat it twice, and dry the processed product in a vacuum oven at 60°C for 24 hours to obtain nano-ferric oxide;

[0079] b) Preparation of γ-methacryloxypropyltrimethoxysilane (KH-570) modified nano-ferric oxide powder: add 3 g of nano-ferric oxide prepared in step a) to a three-necked flask and 100ml of ethanol, ultrasonically disperse for 15min; then add 1ml of ammonia water to the dispersion, move the three-necked flask into a water bath at 30°C for ...

Embodiment 2

[0086] a) according to the method of embodiment 1 step a), prepare nano-ferric oxide powder;

[0087] B) the coupling agent is replaced by KH-560, according to the method of embodiment 1 step b) to prepare KH-560 modified nano ferric oxide powder;

[0088] c) Preparation of acrylic acid-acrylamide copolymer (P(AA-AM)) / Fe 3 o 4 Composite gel microspheres: Add 1.07g of the modified iron ferric oxide prepared in step b) to 30mL of liquid paraffin, and disperse by ultrasonic for 15min to obtain a uniform dispersion, then pour the resulting dispersion into a three-necked flask , moved into a 55°C water bath for mechanical stirring, then added 0.31g of emulsifier Tween 60 (emulsifier T-60), 0.93g of Span 60 (emulsifier S-60), and then took 10ml of liquid paraffin into a three-necked flask , stirred rapidly at a speed of 400r / min for 10min, then added 4.52g of AA, 3.48g of AM, 0.08g of cross-linking agent N,N-methylenebisacrylamide (MBA), 1.63g of NaOH, Adjust the rotation speed t...

PUM

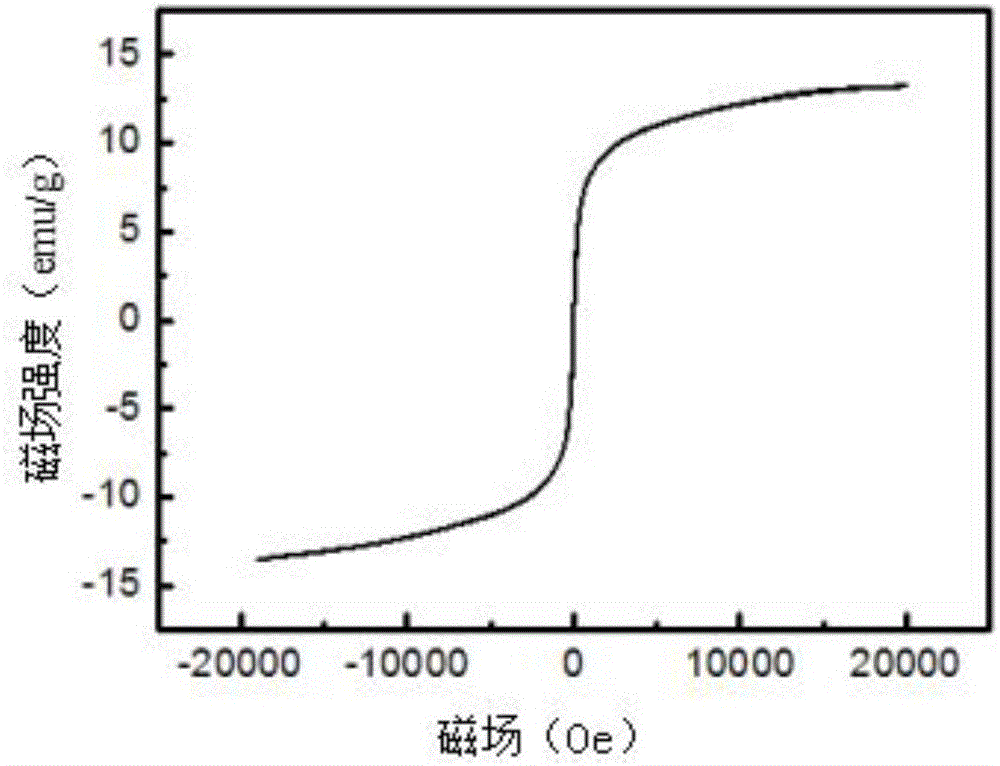

| Property | Measurement | Unit |

|---|---|---|

| Specific saturation magnetization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com