A kind of method that n-butane oxidation prepares maleic anhydride

A technology of n-butane and maleic anhydride, which is applied in the field of catalyst-graded n-butane oxidation to prepare maleic anhydride, can solve the problems of lowering production efficiency, prolonging the stable period, and reducing the effective volume of the reactor, so as to reduce reaction hot spots and reduce reaction time. The intensity is gentle, and the effect of inhibiting the occurrence of side effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] (2) Preparation of vanadium phosphorus oxygen catalyst

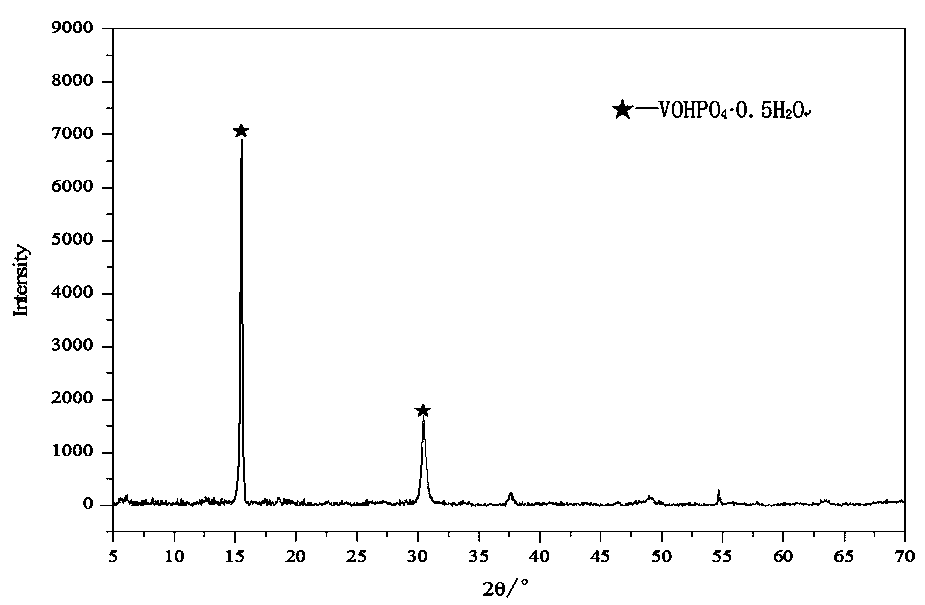

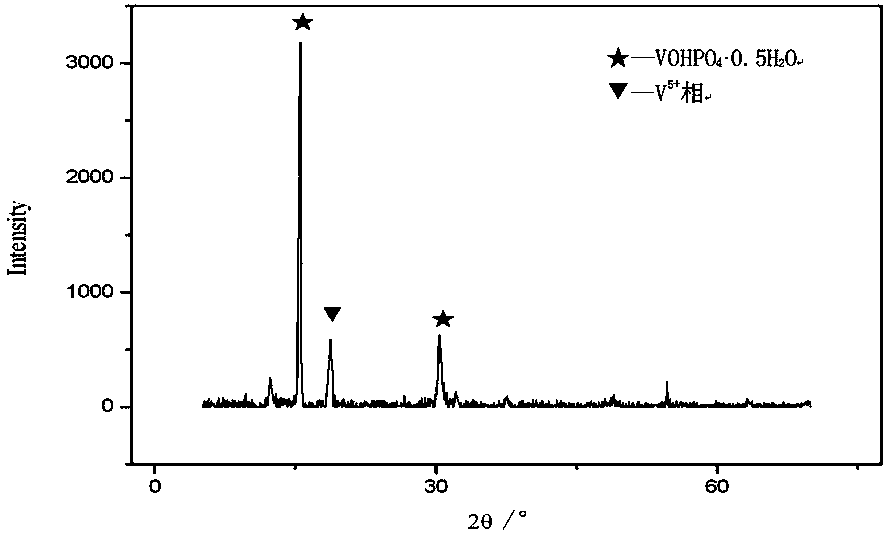

[0045] The vanadium phosphorus oxide obtained in step (1) is first formed, and the shape of the obtained vanadium phosphorus oxygen catalyst can be a pressed tablet, a spherical shape, an extruded rod, etc., and the phase of the obtained catalyst precursor is (VOHPO4 0.5H 2 o).

[0046] (3) Oxidation treatment of vanadium phosphorus oxygen catalyst

[0047] The catalyst particles obtained in step (2) are immersed in an organic solvent containing a certain concentration of organic peroxide, and the average valence state of vanadium in the catalyst is regulated by controlling the concentration of the organic peroxide.

[0048] The mass concentration of organic peroxides is generally controlled at 0.5% to 10%.

[0049] (4) Activation of vanadium phosphorus oxygen catalyst

[0050] After the impregnation in step (3), it is filtered and dried, and the dried catalyst is activated in a nitrogen or inert gas atmosphere...

Embodiment 1

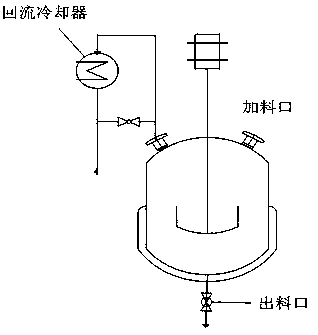

[0056] exist figure 1 Add 649L of isobutanol and benzyl alcohol mixture to the reaction kettle shown with a stirring device and a reflux condensing device, the volume ratio of isobutanol / benzyl alcohol is 10:1, 29.53 kg of vanadium pentoxide, and the auxiliary agent hexahydrate Ferric nitrate 0.3kg, auxiliary agent zirconium nitrate 0.5kg, start stirring, increase the reaction temperature and keep it at 100±2°C, carry out reflux reaction, keep reflux time for 4 hours, then add 34.98kg of phosphoric acid with a concentration of 100%, phosphorus / vanadium The molar ratio was 1.1, the reflux was continued for 4 hours, and the reaction ended. After the reaction solution was cooled to room temperature, it was vacuum filtered, and the filter cake was rinsed three times with a small amount of isobutanol to complete the reaction. After the reaction solution was cooled to room temperature, it was vacuum filtered, and the filter cake was rinsed with a small amount of isobutanol three ti...

Embodiment 2

[0061] exist figure 1 Add 649L of isobutanol and benzyl alcohol mixture to the reaction kettle shown with a stirring device and a reflux condensing device, the volume ratio of isobutanol / benzyl alcohol is 10:1, 29.53 kg of vanadium pentoxide, and the auxiliary agent hexahydrate Ferric nitrate 0.3kg, auxiliary agent zirconium nitrate 0.5kg, start stirring, increase the reaction temperature and keep it at 100±2°C, carry out reflux reaction, keep reflux time for 4 hours, then add 34.98kg of phosphoric acid with a concentration of 100%, phosphorus / vanadium The molar ratio was 1.1, the reflux was continued for 4 hours, and the reaction ended. After the reaction solution was cooled to room temperature, it was vacuum filtered, and the filter cake was rinsed three times with a small amount of isobutanol to complete the reaction. After the reaction solution was cooled to room temperature, it was vacuum filtered, and the filter cake was rinsed with a small amount of isobutanol three ti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com