Transition metal boride-glass ultra-high temperature oxidation resistant composite material and preparation method thereof

A high-temperature anti-oxidation and transition metal technology, which is applied in the field of transition metal boride-glass ultra-high temperature anti-oxidation composite materials and its preparation, can solve the problem of transition metal boride-glass ultra-high temperature anti-oxidation composite materials that have been reported but have not been found yet. Technical and other issues, to achieve the effects of lower sintering temperature, simple implementation, and good thermal erosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

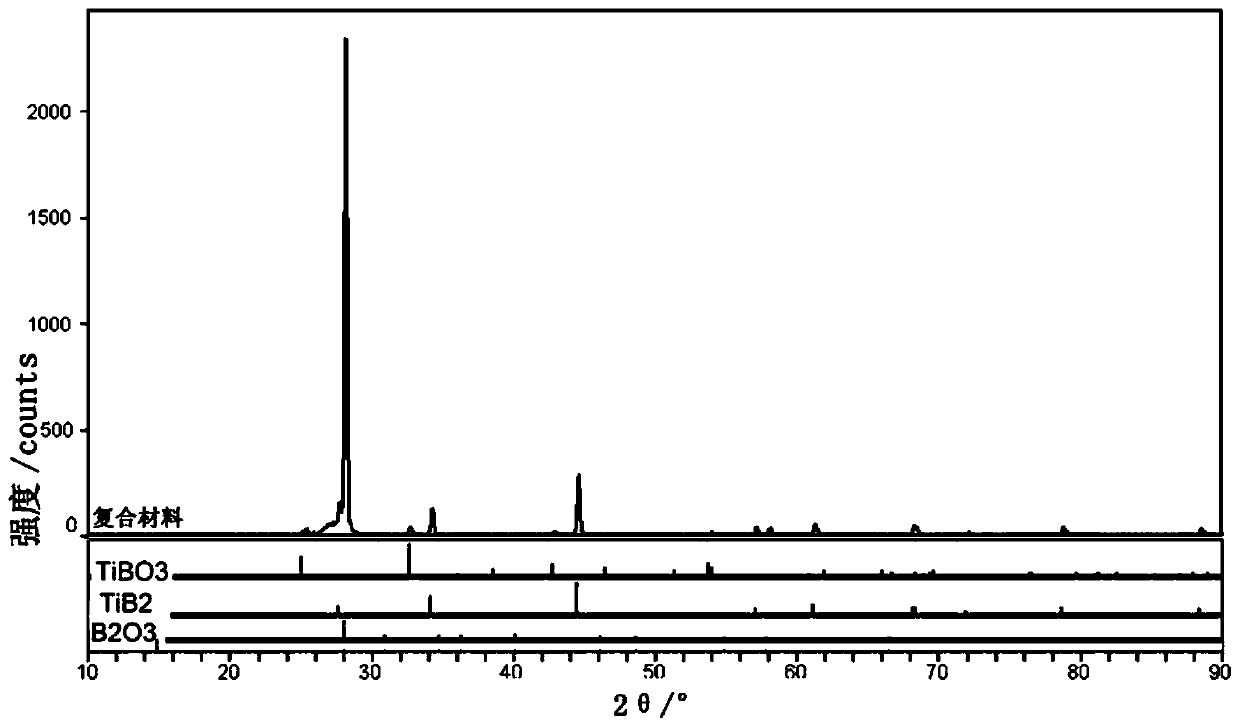

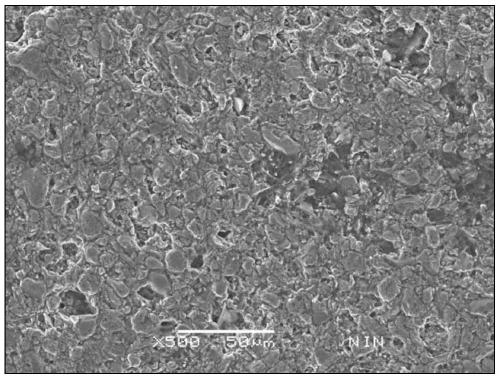

Embodiment 1

[0028] This example proposes a TiB 2 -Glass ultra-high temperature oxidation-resistant composite material, the composite material is made of TiB 2 and glass, the TiB 2 The mass accounts for 95% of the total mass of the composite material. The glass is silicate glass, and its chemical composition is calculated as: B 2 o 3 7%, Al 2 o 3 5%, ZrO 2 3%, CaO 3%, KNO 3 12%, the balance is SiO 2 .

[0029] This embodiment TiB 2 -The preparation method of the glass ultra-high temperature oxidation-resistant composite material comprises the following steps:

[0030] Step 1. TiB with particle size less than 3 μm 2 Put the powder and glass powder with a particle size of less than 5 μm into a high-energy ball mill, and ball mill and mix for 4 hours under the condition of a ball milling rate of 320r / min to obtain a mixed powder;

[0031] Step 2, using a powder tablet press or a cold isostatic press to compact the mixed powder described in step 1, and control the compacting for...

Embodiment 2

[0036] This example proposes a TiB 2 -Glass ultra-high temperature oxidation-resistant composite material, the composite material is made of TiB 2 and glass, the TiB 2 The mass accounts for 90% of the total mass of the composite material. The glass is silicate glass, and its chemical composition is calculated as: B 2 o 3 7%, Al 2 o 3 5%, ZrO 2 3%, CaO 3%, KNO 3 12%, the balance is SiO 2 .

[0037] This embodiment TiB 2 -The preparation method of the glass ultra-high temperature oxidation-resistant composite material comprises the following steps:

[0038] Step 1. TiB with particle size less than 3 μm 2 The powder and glass powder with a particle size of less than 5 μm are added to a high-energy ball mill, and ball milled and mixed for 2 hours under the condition of a ball milling rate of 500 r / min to obtain a mixed powder;

[0039] Step 2, using a powder tablet press or a cold isostatic press to compact the mixed powder described in step 1, and control the compr...

Embodiment 3

[0044] This example proposes a ZrB 2 -Glass ultra-high temperature oxidation-resistant composite material, the composite material is made of ZrB 2 and glass, the ZrB 2 The mass accounts for 90% of the total mass of the composite material. The glass is silicate glass, and its chemical composition is calculated as: B 2 o 3 20%, Al 2 o 3 2%, ZrO 2 10%, SrO 3%, Na 2 O 5%, the balance is SiO 2 .

[0045] In this embodiment ZrB 2 -The preparation method of the glass ultra-high temperature oxidation-resistant composite material comprises the following steps:

[0046] Step 1, ZrB with particle size less than 3 μm 2 Put the powder and glass powder with a particle size of less than 5 μm into a high-energy ball mill, and ball mill and mix for 6 hours under the condition of a ball milling rate of 200r / min to obtain a mixed powder;

[0047] Step 2, using a powder tablet press or a cold isostatic press to compress the mixed powder described in step 1, and control the compressi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com