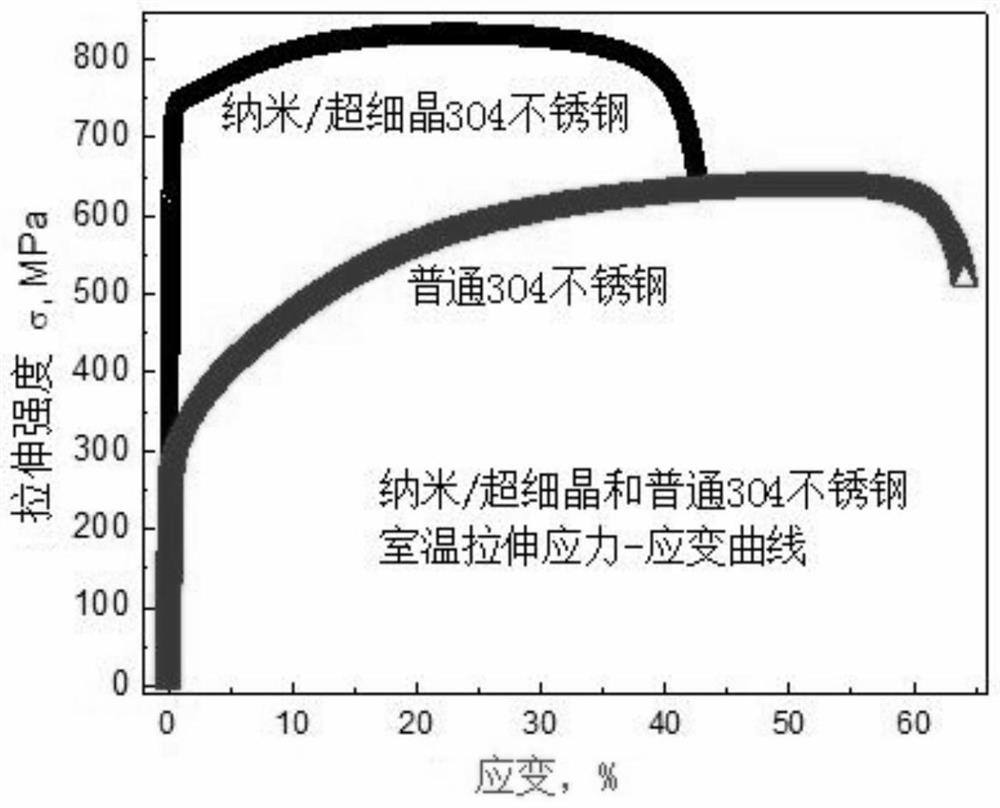

Processing method of high-strength, corrosion-resistant and fatigue-resistant nano/ultra-fine grain 304 stainless steel

A technology of 304 stainless steel and processing method, which is applied in the field of corrosion resistance and anti-fatigue nano/ultra-fine grain 304 stainless steel processing and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] In this embodiment, a high-strength, corrosion-resistant and fatigue-resistant nano / ultra-fine grain 304 stainless steel processing method, the process steps are as follows:

[0052] Step S1: remove scale and other sundries on the surface of common 304 stainless steel.

[0053] Step S2: Homogenization heat treatment of ordinary 304 stainless steel: heat preservation at 1050° C. for 3 hours.

[0054] Step S3: the rolling temperature and deformation rate of the first pass are 1000° C. and 25% respectively.

[0055] Step S4: The rolling temperature and deformation rate of the second pass are 900° C. and 20%, respectively.

[0056] Step S5: The rolling temperature and deformation rate of the third pass are 800°C and 15%, respectively.

[0057] Step S6: The rolling temperature and deformation rate of the fourth pass are 750° C. and 10% respectively, and the rolling temperature and deformation rate of the fifth pass are 700° C. and 10% respectively.

[0058] Step S7: the f...

Embodiment 2

[0061] In this embodiment, a high-strength, corrosion-resistant and fatigue-resistant nano / ultra-fine grain 304 stainless steel processing method, the process steps are as follows:

[0062] Step S1: remove scale and other sundries on the surface of common 304 stainless steel.

[0063] Step S2: Homogenization heat treatment of ordinary 304 stainless steel: heat preservation at 1000° C. for 6 hours.

[0064] Step S3: the rolling temperature and deformation rate of the first pass are 900° C. and 20%, respectively.

[0065] Step S4: The rolling temperature and deformation rate of the second pass are 800° C. and 10%, respectively.

[0066] Step S5: The rolling temperature and deformation rate of the third pass are 700° C. and 10% respectively.

[0067] Step S6: the rolling temperature and deformation rate of the fourth pass are 650°C and 15% respectively, and the rolling temperature and deformation rate of the fifth pass are 600°C and 15% respectively.

[0068] Step S7: the fina...

Embodiment 3

[0071] In this embodiment, a high-strength, corrosion-resistant and fatigue-resistant nano / ultra-fine grain 304 stainless steel processing method, the process steps are as follows:

[0072] Step S1: remove scale and other sundries on the surface of common 304 stainless steel.

[0073] Step S2: Homogenization heat treatment of ordinary 304 stainless steel: heat preservation at 1020° C. for 4 hours.

[0074] Step S3: the rolling temperature and deformation rate of the first pass are 950° C. and 25% respectively.

[0075] Step S4: The rolling temperature and deformation rate of the second pass are 850° C. and 15%, respectively.

[0076] Step S5: The rolling temperature and deformation rate of the third pass are 750° C. and 12%, respectively.

[0077] Step S6: The rolling temperature and deformation rate of the fourth pass are 700°C and 12%, respectively, and the rolling temperature and deformation rate of the fifth pass are 650°C and 10%, respectively.

[0078] Step S7: the fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com