Novel cementing material with carbon sequestration capacity, and preparation and application method thereof

A gelling material and capacity technology, applied in the field of new gelling material with carbon sequestration capacity and its preparation and use, can solve the problems of large consumption of fossil resources, high pollution, high energy consumption, etc., and achieve low energy consumption and hydration process Fast, intensity-building effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

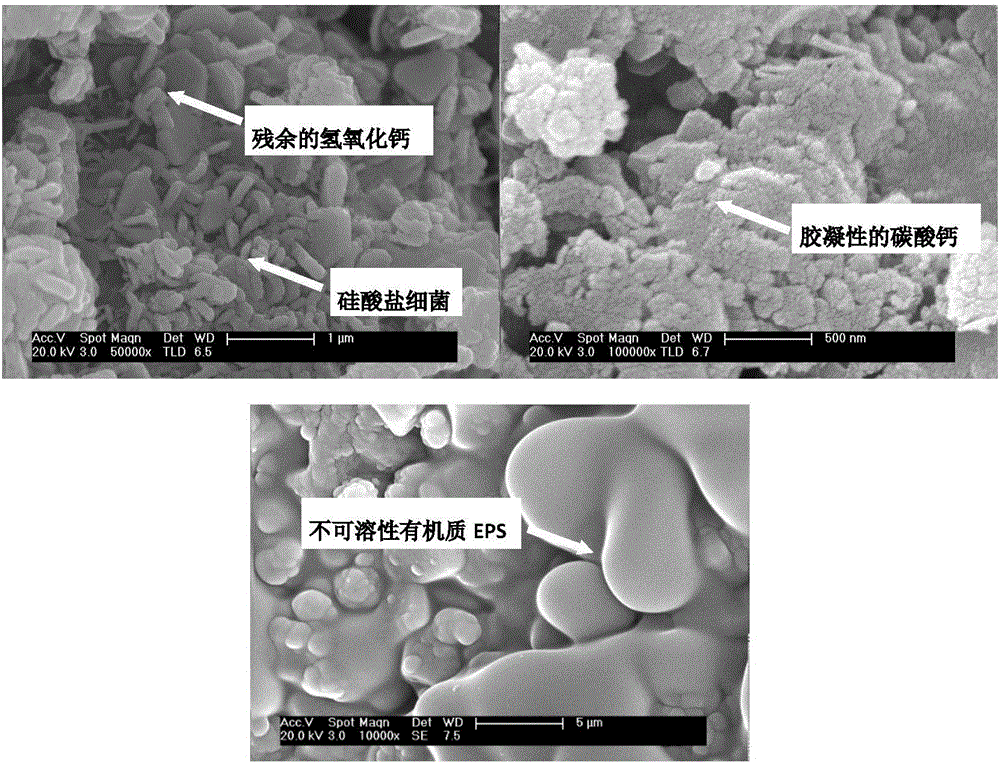

[0031] (1) Weigh 5g peptone, 3g beef extract, 5g NaCl, MnSO 4 ·H 2 O is 5mg, dissolved in 1000mL deionized water, prepared into the required medium solution, adjusted to pH 7, sterilized at 125°C for 25 minutes, then taken out to be cooled, and inoculated into the cooling medium solution with Bacillus glaciens, Cultivate with shaking at 37°C, with an oscillation frequency of 170r / min, and a culture time of 24h;

[0032] (2) Using porous gypsum as the wall material, silicate bacteria as the core material, spray drying, the inlet air temperature is controlled at 150°C; the outlet air temperature is controlled at 80°C, and the final load is 5.0×10 9 Cells / gram, prepared into silicate bacterial powder;

[0033] (3) Mixing 20 parts of silicate bacterial powder and 100 parts of calcium hydroxide to prepare the gelling material of the present invention;

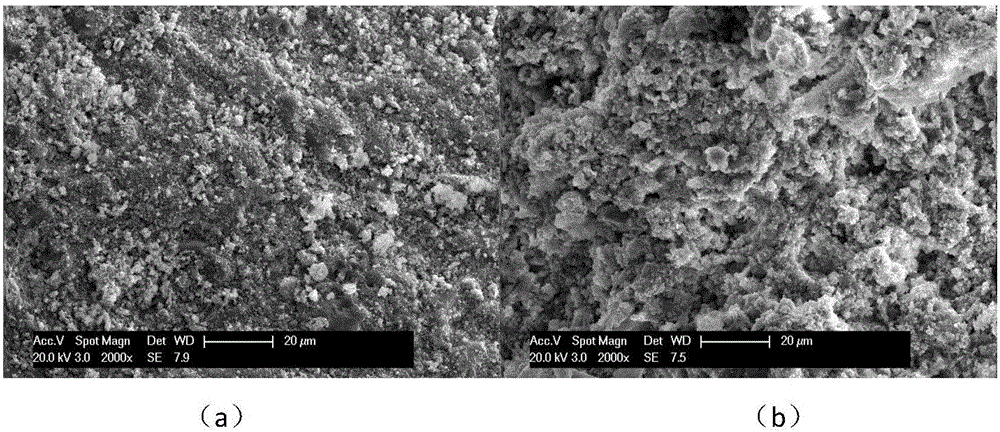

[0034] (4) Mix 25 parts of the cementitious material with 10 parts of water and form it. After standing for 48 hours, put it in a carbon ...

Embodiment 2

[0036] (1) Weigh 5g peptone, 3g beef extract, 5g NaCl, MnSO 4 ·H 2 O is 5mg, dissolved in 1000mL deionized water, prepared into the required medium solution, adjusted to pH 7, sterilized at 125°C for 25 minutes, then taken out to be cooled, and inoculated into the cooling medium solution with Bacillus glaciens, Cultivate with shaking at 37°C, with an oscillation frequency of 170r / min, and a culture time of 24h;

[0037] (2) Using porous gypsum as the wall material, silicate bacteria as the core material, spray drying, the inlet air temperature is controlled at 150°C; the outlet air temperature is controlled at 80°C, and the final load is 5.0×10 9 Cells / gram, prepared into silicate bacterial powder;

[0038] (3) Mixing 20 parts of silicate bacterial powder and 100 parts of calcium hydroxide to prepare the gelling material of the present invention;

[0039] (4) 25 parts of the gelling material and 10 parts of water are mixed and molded. Compared with Example 1, the previous steps are c...

Embodiment 3

[0041] (1) 20 parts of gypsum and 100 parts of calcium hydroxide are mixed to prepare a cementitious material, compared to Example 1 without microorganisms;

[0042] (2) Mix 25 parts of the cementitious material with 10 parts of water and form it. After standing for 48 hours, put it in a carbon dioxide autoclave at a temperature of 20°C, a relative humidity of 60%, and maintain a pressure of 0.3MPa. 2 With a gas concentration of 99% and keeping aeration for 180 minutes, the cementitious material has also been consolidated. Its compressive strength is 3.91MPa, as shown in Table 1.

[0043] Analysis of the results of Example 1, Example 2, and Example 3:

[0044] Compared with Example 1, all the preparation methods of Example 2 are basically the same. The difference is that after the sample of Example 2 is left for 48 hours, it is not put into a carbon dioxide autoclave for further curing for 3 hours, and its strength is only 0.56 MPa; Example 1 After 3 hours of carbon dioxide pressure ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com