Water treatment agent for improving ammonia nitrogen removal ability of biochemical system

A technology of biochemical system and water treatment agent, which is applied in special compound water treatment, biological water/sewage treatment, water/sludge/sewage treatment, etc. It can solve the side effects of water body and other problems, meet the requirements of reducing living conditions and enhance adaptability performance and improve decomposition efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

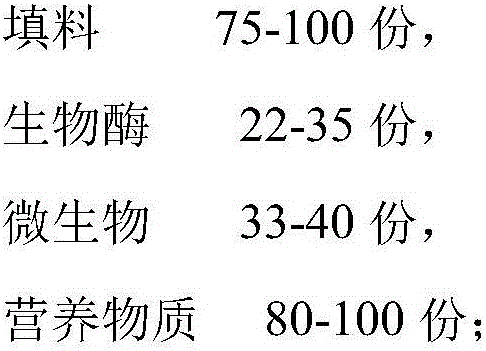

Method used

Image

Examples

Embodiment 1

[0024] 1. Weighing

[0025] Filler: sludge 20g, diatomite 45g, nano titanium dioxide 10g;

[0026] Biological enzymes: protease 5g, amylase 6g, cellulase 7g, lipase 8g;

[0027] Microorganisms: 15g halophilic bacteria, 10g heterotrophic nitrifying bacteria, 10g denitrifying bacteria;

[0028] Nutrients: vitamin 10g, amino acid 20g, sucrose 20g, whey 20g, sodium chloride 15g;

[0029] 2. Microbial culture

[0030] The halophilic bacteria, heterotrophic nitrifying bacteria, and denitrifying bacteria that were weighed in step 1 were grown in the culture medium. After passing the test, the first-generation inoculum was transferred to a sterile 250-liter bio-fermenter. 24 hours of growth at room temperature, and then made into bacterial liquid for later use;

[0031] 3. Mix

[0032] Mix the bacterial liquid prepared in step 2 and the biological enzyme weighed in step 1 in a container, add nutrients and fillers into the above container after fully mixing, and mix again to prepa...

Embodiment 2

[0035] 1. Weighing

[0036] Filler: sludge 25g, diatomite 50g, nano titanium dioxide 20g;

[0037] Biological enzymes: protease 7g, amylase 5g, cellulase 6g, lipase 4g;

[0038] Microorganisms: 14g halophilic bacteria, 15g heterotrophic nitrifying bacteria, 11g denitrifying bacteria;

[0039] Nutrients: vitamin 9g, amino acid 18g, sucrose 20g, whey 19g, sodium chloride 14g;

[0040] 2. Microbial culture

[0041] The halophilic bacteria, heterotrophic nitrifying bacteria, and denitrifying bacteria that were weighed in step 1 were grown in the culture medium. After passing the test, the first-generation inoculum was transferred to a sterile 250-liter bio-fermenter. 24 hours of growth at room temperature, and then made into bacterial liquid for later use;

[0042] 3. Mix

[0043] Mix the bacterial liquid prepared in step 2 and the biological enzyme weighed in step 1 in a container, add nutrients and fillers into the above container after fully mixing, and mix again to prepar...

Embodiment 3

[0046] 1. Weighing

[0047] Filler: sludge 35g, diatomite 58g, nano titanium dioxide 20g;

[0048] Biological enzymes: protease 11g, amylase 9g, cellulase 8g, lipase 7g;

[0049] Microorganisms: 17 g of halophilic bacteria, 8 g of heterotrophic nitrifying bacteria and 8 g of denitrifying bacteria;

[0050] Nutrients: vitamin 7g, amino acid 30g, sucrose 25g, whey 28g, sodium chloride 10g;

[0051] 2. Microbial culture

[0052] The halophilic bacteria, heterotrophic nitrifying bacteria, and denitrifying bacteria that were weighed in step 1 were grown in the culture medium. After passing the test, the first-generation inoculum was transferred to a sterile 250-liter bio-fermenter. 24 hours of growth at room temperature, and then made into bacterial liquid for later use;

[0053] 3. Mix

[0054] Mix the bacterial liquid prepared in step 2 and the biological enzyme weighed in step 1 in a container, add nutrients and fillers into the above container after fully mixing, and mix aga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com