Composite micro-electrolysis filler for treating the hardly degradable wastewater and preparation method thereof

A wastewater treatment and micro-electrolysis technology, applied in water/sewage treatment equipment, water/sewage treatment, adsorbed water/sewage treatment, etc., can solve the problems of weak COD removal ability, low use efficiency, and easy occurrence of hardening, etc. Achieving the effect of being beneficial to industrialized large-scale production, improving efficiency and enhancing adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Example 1: A composite micro-electrolytic filler for refractory wastewater treatment and its preparation method

[0036] A composite micro-electrolytic filler for refractory wastewater treatment, prepared from the following components by weight: 45 parts of iron powder; 15 parts of activated carbon powder; 8 parts of cerium powder; 8 parts of lanthanum powder; 15 parts of sodium bentonite; 10 parts of polyaluminum chloride; 10 parts of Portland cement. Wherein, the particle diameter of iron powder is 2-5mm; The diameter of described activated carbon powder, cerium powder, lanthanum powder is 60-80 mesh; The diameter of described sodium bentonite is 200 mesh; The diameter of described molecular sieve is 1- 2mm; the polyaluminum chloride is a yellow powder with a basicity of more than 50% and an Al2O3 content of more than 9.5%.

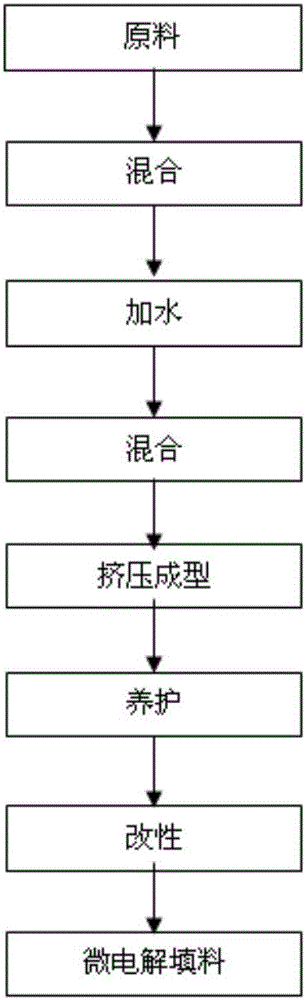

[0037] The preparation method of the micro-electrolytic filler for the treatment of difficult-to-biochemical wastewater comprises the following...

Embodiment 2

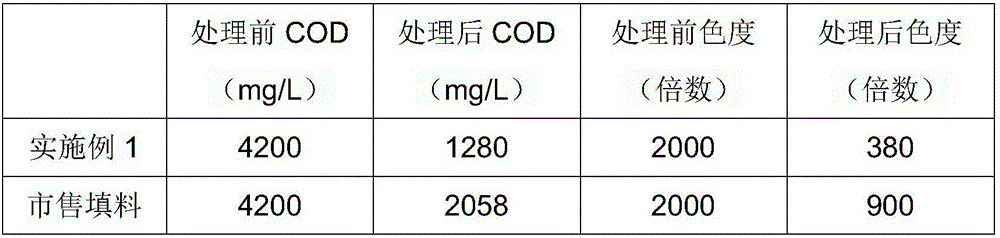

[0042] Example 2: Comparative test of micro-electrolytic fillers prepared by the present invention and commercially available micro-electrolytic fillers for refractory wastewater treatment

[0043] In 2 parallel cylindrical reactors (high 80cm, diameter 10cm), add aeration head, pack into respectively the micro-electrolysis filler that the embodiment 1 of 50cm prepares and commercially available micro-electrolysis filler, respectively to 4 Add waste water from the printing and dyeing industry (COD is 4200mg / L, chromaticity is 2000 times) into a reactor, add to the 60cm of the reactor, open the aeration, control the dissolved oxygen to 2mg / L, after 2 hours of reaction, Let it settle for 30 minutes, take the supernatant, and test the COD and chromaticity.

[0044] Table 1 Comparative test results of refractory wastewater treatment

[0045]

[0046] From the above results, it can be seen that when treating refractory wastewater, the COD degradation rate of the micro-electroly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com