Adsorbent for removing trace halides in gas as well as preparation method and application thereof

A halide and adsorbent technology, applied in chemical instruments and methods, separation methods, alkali metal compounds, etc., to achieve the effects of long service life, high dispersion and stability, and high adsorption activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

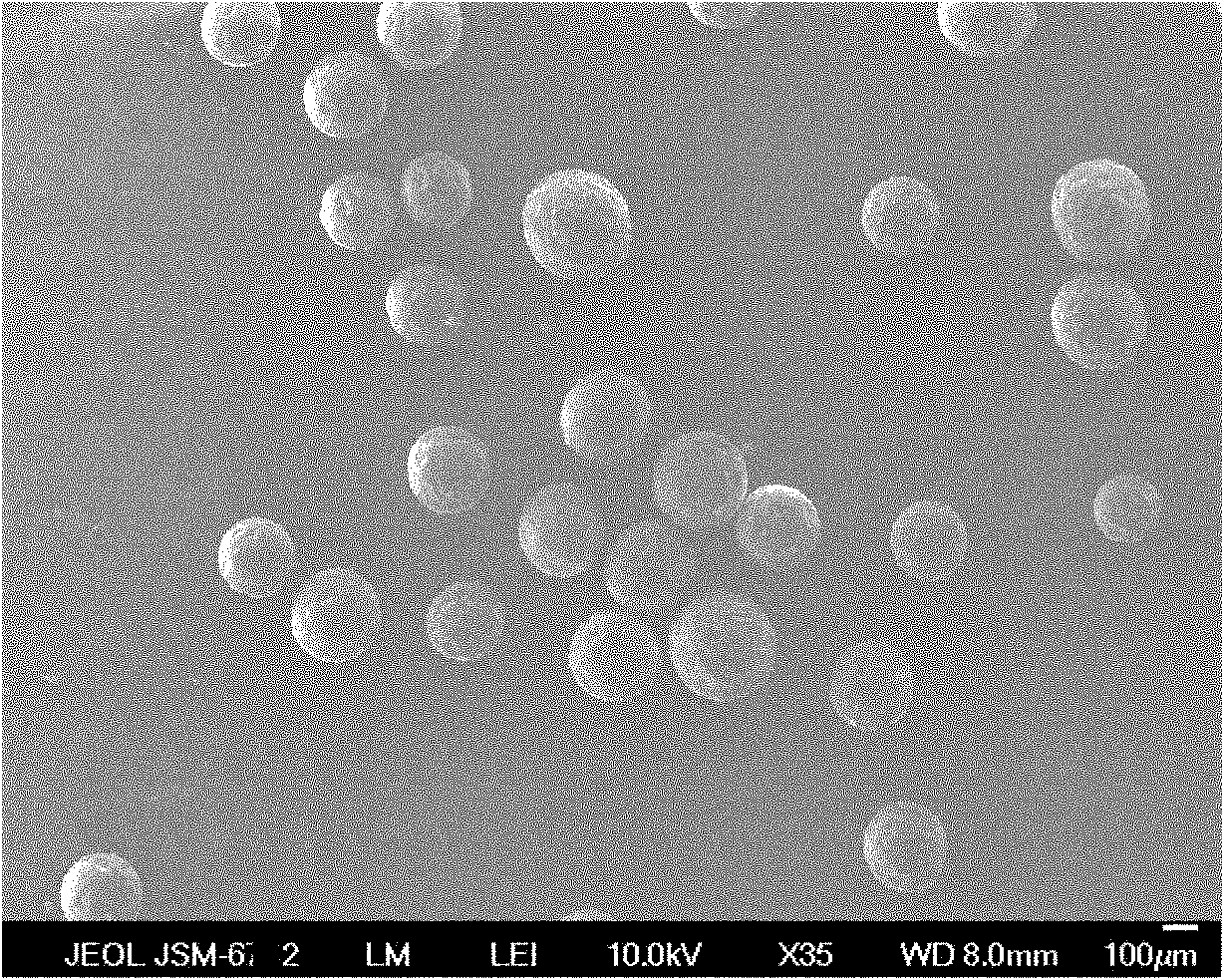

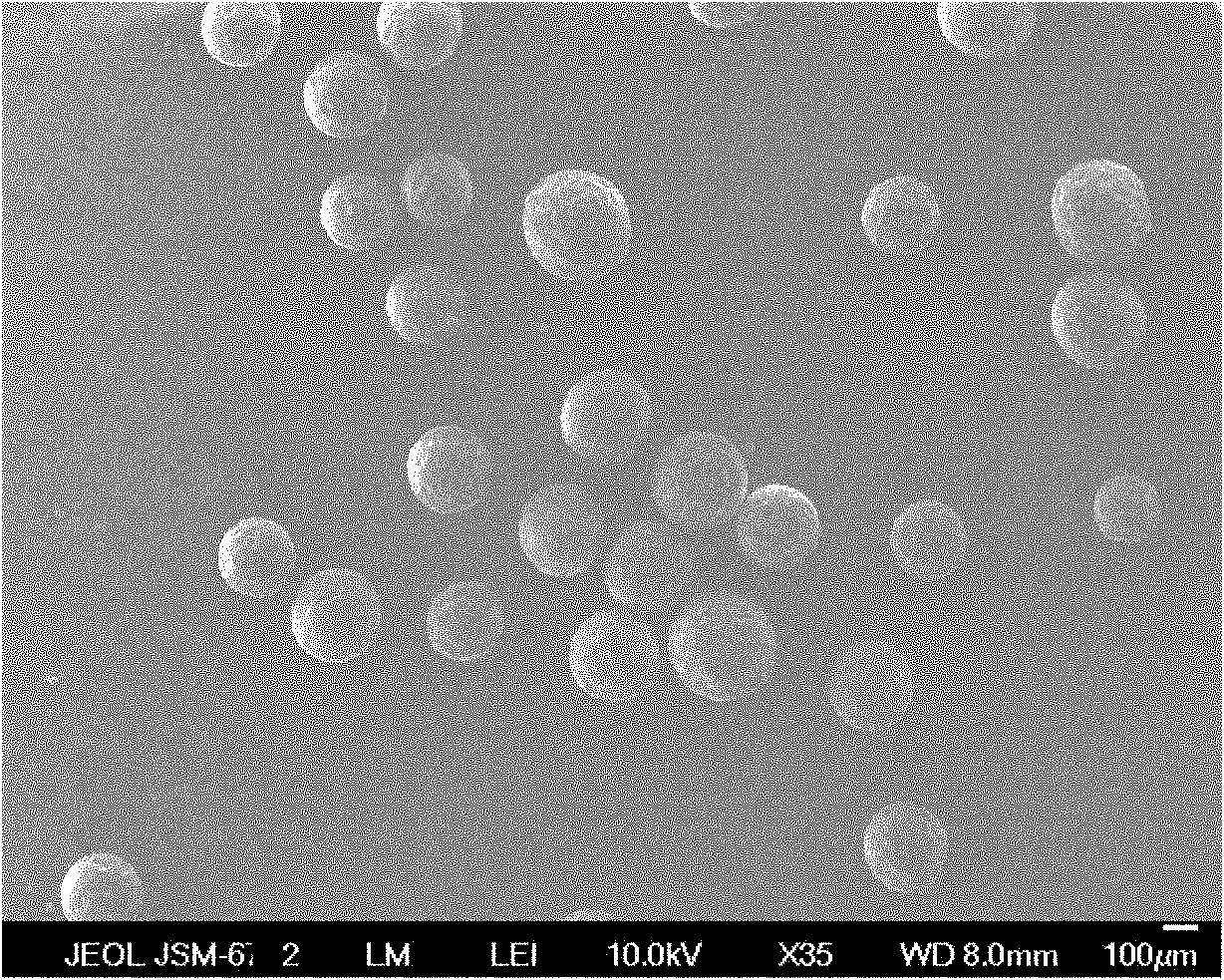

[0031] Embodiment 1. Preparation of adsorbent

[0032] The polymer precursor is a polymer ball obtained by suspension copolymerization of vinylidene chloride and acrylonitrile, and the molar content of acrylonitrile in the vinylidene chloride is 1.0%. Ultrafine bentonite was used as synthesis template and dispersed phase. Add the mixture of the two monomers (containing 1.5% molar content of azobisisoheptanonitrile) dropwise into the saturated aqueous sodium sulfate solution under stirring, and the polymerization reaction is continued at 45°C and the stirring speed is 500r / min. for 10h. The obtained copolymer pellets were washed with distilled water to remove bentonite on the surface, and washed with hot acetone to remove residual monomers. Carbonization of the polymer pellets takes place in a quartz tube, heated by a temperature-programmed electronic furnace. After treatment at 175 °C for 16 h, the heating temperature was increased to 300 °C at a rate of 1 °C / min and kept a...

Embodiment 2

[0035] The adsorbent prepared in Example 1 was packed in a fixed-bed reactor with a volume of 1 L, and the aspect ratio of the reactor was 3. Nitrogen containing 0.1% of the molar content of monochloromethane is passed through the reactor, the flow rate of the gas is controlled at 3L / min, the temperature of the reactor is 50°C, and the gas flowing out of the reactor is monitored by gas chromatography, and the halogenated gas in the gas is The efficient removal rate of hydrocarbons is 99.98%.

Embodiment 3

[0037] The adsorbent prepared in Example 1 was packed in a fixed-bed reactor with a volume of 1 L, and the aspect ratio of the reactor was 3. Argon gas containing chloroform molar content of 0.05% is passed through the reactor, the flow rate of the gas is controlled to 2L / min, the temperature of the reactor is 50°C, and the gas flowing out of the reactor is monitored by gas chromatography, the halogen in the gas The efficient removal rate of substituted hydrocarbons is 99.99%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com