Granularity-controllable magnesium hydroxide reaction crystallization apparatus and process

A technology of reactive crystallization and magnesium hydroxide, which is applied in the directions of magnesium hydroxide, general layout of crystallization equipment, and crystallization separation, etc., can solve the problems of wide particle size distribution, difficult filtration, small addition amount, etc., and achieve the effect of narrow particle size distribution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

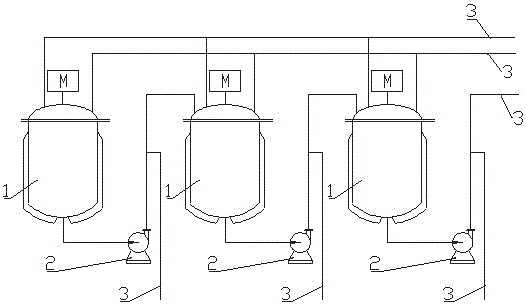

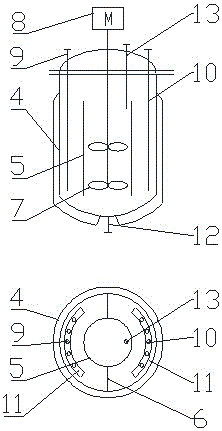

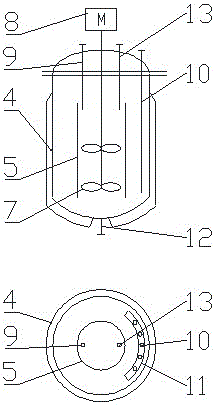

[0037]The reaction crystallization device is composed of three stages of above-mentioned magnesium hydroxide reaction crystallizers (1). The crystallizer stirring blade (7) adopts 2 layers of down-pressing type propeller blades; a longitudinal partition (6) is installed between the jacketed kettle body (4) and the guide tube (5); the magnesium chloride feeding pipe (9) The outlet of the sodium hydroxide feed pipe (10) is located outside the guide tube (5), and the height of the nozzle is located at 20 cm above the lower edge of the guide tube (5), respectively arranged on the two sides of the longitudinal partition (6). Side; the diameter of the diversion cylinder (5) is 0.4 times of the inner diameter of the jacketed still body (4), and the lower edge of the diversion cylinder (5) is 15cm away from the bottom of the jacketed still body (4).

[0038] Add a sodium chloride solution with a mass concentration of 15% in each reaction crystallizer (1) as the reaction crystallizatio...

Embodiment 2

[0042] A reaction crystallization device is composed of six stages of above-mentioned magnesium hydroxide reaction crystallizers (1). The crystallizer stirring paddle (7) adopts 3 layers of down-pressing type propeller blades. A vertical partition (6) is installed between the jacketed still body (4) and the guide tube (5) of the first, second, and third-stage reaction crystallizers; the magnesium chloride feed pipe (9) mouth and the sodium hydroxide feed The mouths of the pipes (10) are all located outside the guide tube (5), and the nozzle heights are all located at 5 cm above the lower edge of the guide tube (5), and are respectively arranged on both sides of the longitudinal partition (6); the guide tube (5) ) diameter is 0.5 times of the inner diameter of the jacketed still body (4), and the lower edge of the draft tube (5) is 20cm away from the bottom of the jacketed still body (4). In the jacketed still body (4) of the 4th, 5th, and 6th stage reaction crystallizers, lon...

Embodiment 3

[0047] A reaction crystallization device is formed by adopting five stages of above-mentioned magnesium hydroxide reaction crystallizers (1). The crystallizer stirring paddle (7) adopts 3 layers of down-pressing type propeller blades. In the jacketed still body (4) of the 1st, 2nd, and 3rd stage reaction crystallizers, longitudinal partitions (6) are not installed, and the sodium hydroxide feed pipe (10) mouth is located in the guide tube (5). 5 cm below the upper edge of the flow tube (5); the magnesium chloride feed pipe (9) mouth is located outside the flow guide tube (5), 30 cm above the lower edge of the flow guide tube (5); the diameter of the flow guide tube (5) is jacketed 0.7 times of the inner diameter of the still body (4), the lower edge of the draft tube (5) is 40cm away from the bottom of the jacketed still body (4). Install vertical partition (6) between the jacketed still body (4) of the 4th, 5th grade reaction crystallizer and guide tube (5); Magnesium chlori...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average particle size | aaaaa | aaaaa |

| Average particle size | aaaaa | aaaaa |

| Average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com