High-ignition-point granular active carbon and preparation method thereof

A technology of granular activated carbon and ignition point, which is applied in the direction of chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., can solve the problems of obvious decrease in product adsorption, high energy consumption, and complicated preparation process, and achieve a wide range of product applications and high strength. High efficiency, low energy consumption and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] A preparation method for high ignition point granular activated carbon, comprising the steps of:

[0028] The first step, raw material pretreatment: sieve the sawdust to remove impurities, dry, and control the moisture content below 5%;

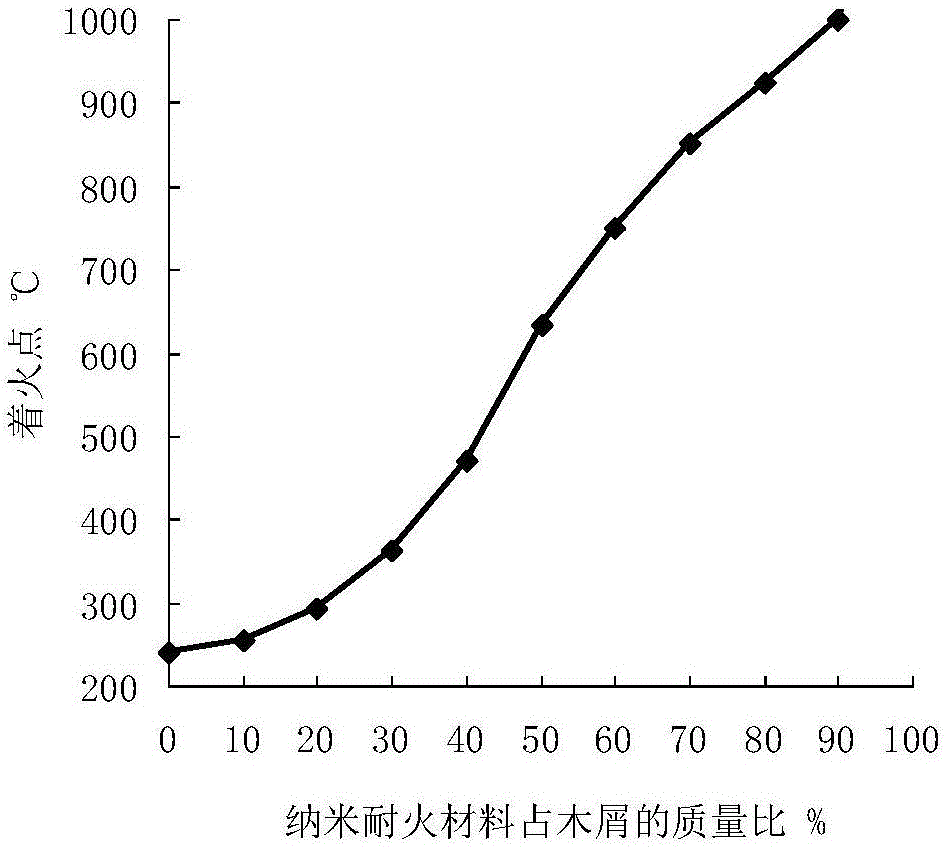

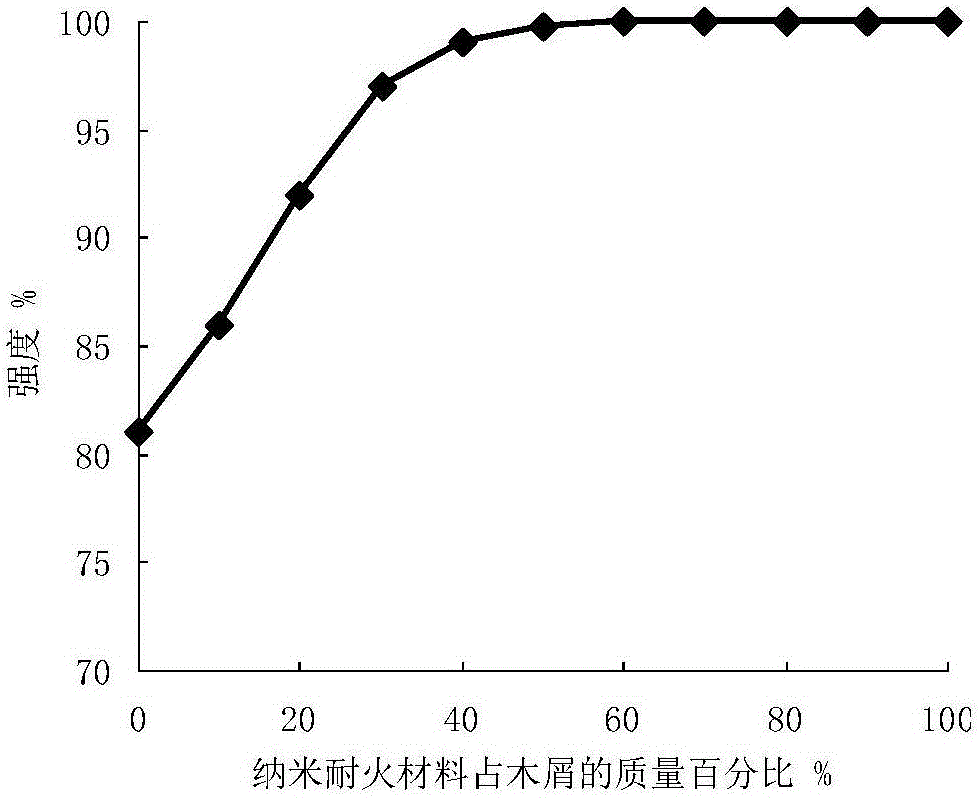

[0029] The second step, molding: mix the above-mentioned sawdust with an activator and a high ignition point modifier, impregnate for 24 hours, then plasticize the rollers for molding, and dry and harden. The activator is phosphoric acid or zinc chloride, and the activator is configured as An aqueous solution with a mass concentration of 20-60%, the mass ratio of activator to wood chips is 1: (1-10), and the high ignition point improver includes one or more mixtures of calcium, magnesium oxide and silicate , the mass ratio of sawdust to high ignition point modifier is 1: (0.1~1), and the plasticizing temperature is 50℃~300℃;

[0030] Step 3: Activation: Put the dry and hardened molding material into the activation reactor, heat up to ...

Embodiment 1

[0038] (1) Screening of fir sawdust: screen the sawdust to remove impurities, dry, and control the moisture at 5%.

[0039] (2) Molding: Phosphoric acid is configured into an aqueous solution with a mass concentration of 20%, mixed with wood chips at a mass ratio of 1:1, and then nano-sized MgO is added at a mass ratio of 1:0.1, fully mixed, soaked for 24 hours, at 50°C Plasticize at low temperature for 1 hour, roll forming, and dry at 150°C for 6 hours to harden.

[0040] (3) Activation: Put the dried and hardened molding material into the activation reactor, heat up to the final activation temperature of 300 °C at a heating rate of 1 °C / min, and maintain it for 0.5 hours. After the activation is completed, cool, wash and recover the activator, and dry it to obtain Activated carbon products. Activated carbon has a fire point of 270°C, a strength of 80%, an Alan value of 100mg / g, and a caramel decolorization rate of 60%.

Embodiment 2

[0042] (1) Screening of fir sawdust: screen the sawdust to remove impurities, dry, and control the moisture at 5%.

[0043] (2) Molding: Prepare zinc chloride into an aqueous solution with a mass concentration of 35%, mix it with sawdust at a mass ratio of 1:8, and then add 100 mesh MgO and SiO at a mass ratio of 1:0.3 2 (Its mass ratio is 1:2) powder, fully mixed, impregnated for 24 hours, plasticized at 50°C for 1 hour, formed on a pair of rolls, dried at 150°C for 6 hours and hardened.

[0044] (3) Activation: Put the dried and hardened molding material into the activation reactor, heat up to the final activation temperature of 300 °C at a heating rate of 1 °C / min, and maintain it for 0.5 hours. After the activation is completed, cool, wash and recover the activator, and dry it to obtain Activated carbon products. Activated carbon has a fire point of 380°C, a strength of 80%, an Alan value of 100mg / g, and a caramel decolorization rate of 60%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| ignition point | aaaaa | aaaaa |

| ignition point | aaaaa | aaaaa |

| ignition point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com