Full-carbon fiber composite material reflecting mirror substrate and preparation method thereof

A composite material and carbon fiber technology, applied in chemical instruments and methods, lamination devices, lamination, etc., can solve the problems of high thermal expansion coefficient, heavy mirror weight, thermal performance mismatch, etc., and achieve high modulus and low density , easy-to-implement effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with accompanying drawing description and specific embodiment:

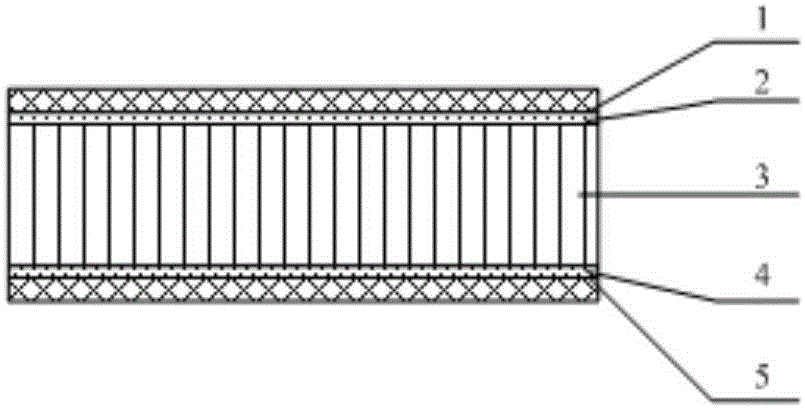

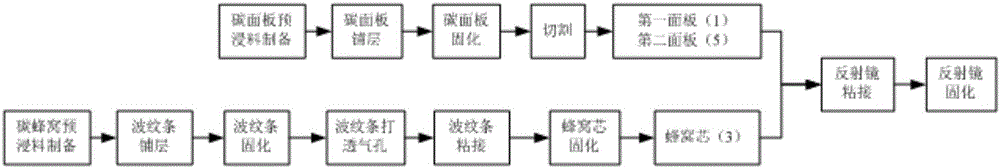

[0036] like figure 1 As shown, an all-carbon fiber composite mirror substrate includes a first panel 1, a first adhesive film 2, a honeycomb core 3, a second adhesive film 4 and a second panel 5; the first panel 1 and the first adhesive film 2 One side is bonded, one side of the second panel 5 and the second adhesive film 4 are bonded, and the other side of the first adhesive film 2 and the other side of the second adhesive film 4 are respectively bonded to both sides of the honeycomb core 3 .

[0037] Preferably, the first panel 1, the honeycomb core 3, and the second panel 5 are all made of high-modulus carbon fiber reinforced low-hygroscopicity resin-based composite materials.

[0038] Both the first adhesive film 2 and the second adhesive film 4 adopt medium-temperature structural adhesive films.

[0039] The thickness ratio of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| modulus | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com