Welding method of hastelloy tube

A welding method and technology of Hastelloy, applied in welding equipment, welding accessories, metal processing and other directions, can solve the problems of poor thermal conductivity, not easy to melt, and lack of penetration, to prevent oxidation and poor forming, avoid cracks, The effect of preventing molding defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

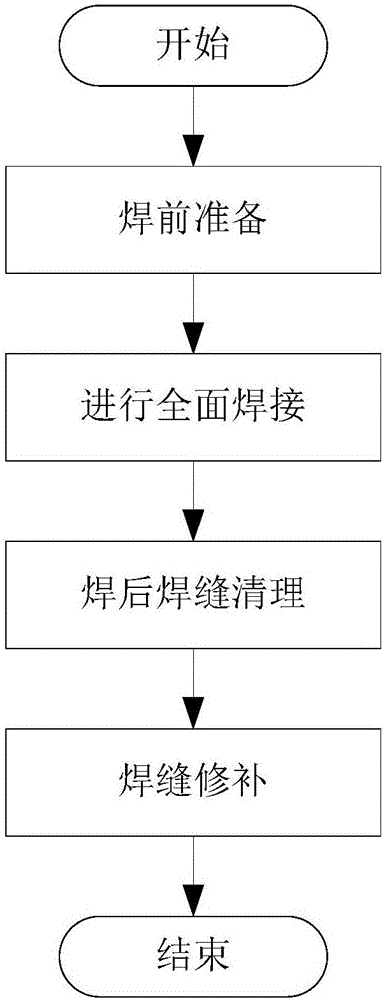

[0034] Such as figure 1 As shown, the Hastelloy tube welding method disclosed in the present invention includes the following steps:

[0035] Step 1, preparation before welding, the specific steps are:

[0036] Step 1.1, bevel preparation, the pipe welding position is made into a bevel in the form of a large angle and a small blunt edge;

[0037] Step 1.2, clean up before welding, clean up oil stains, burrs, rust spots and oxide scale within 20mm on both sides of the groove on the inner and outer surfaces of the pipe;

[0038] Step 1.3: Weld joints are paired, and the pipes to be welded are welded to ensure that the inner wall is flush and the amount of misalignment is less than 10% of the wall thickness;

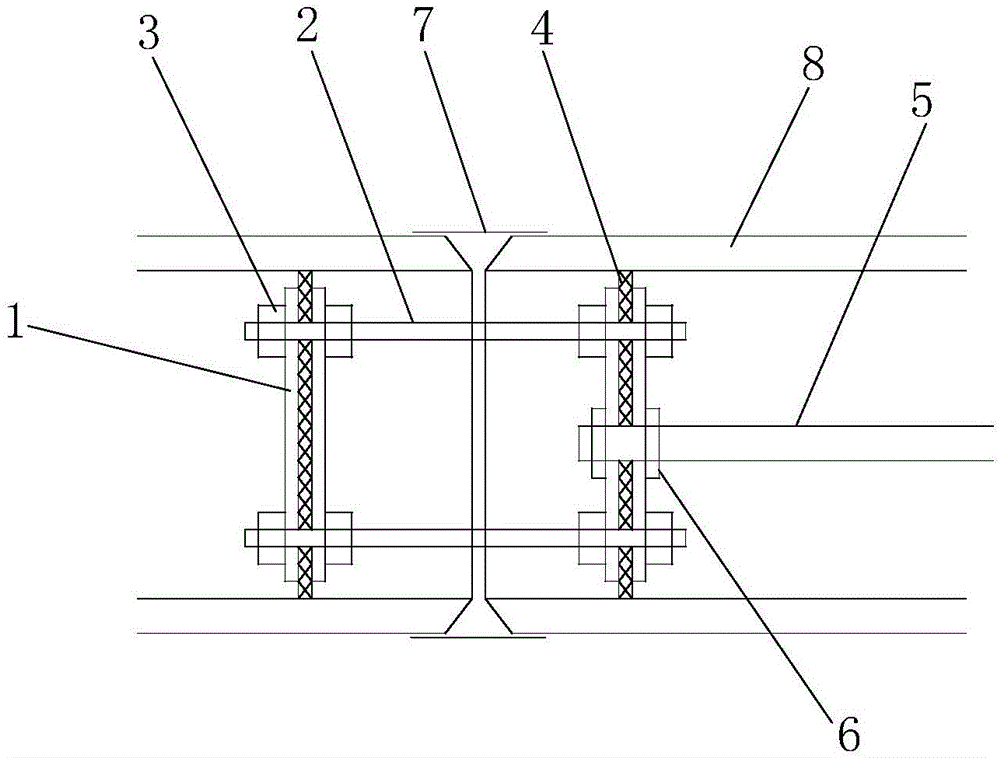

[0039] Step 1.4, install an argon gas protection device, install an argon gas protection device inside the opposite part of the weld seam group of the pipe, and protect the back of the weld seam with argon;

[0040] Step 1.5, tack welding, tack welding is performed at equal intervals ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com