Preparing method for particle reinforcement aluminum matrix composite large-size thick-wall pipe material

A technology of particle-reinforced aluminum and composite materials, which is applied in the field of manufacturing large-sized thick-walled pipes of particle-reinforced aluminum-based composite materials, can solve the problems of high cost, need, and long process route, and achieve good plasticity, cost reduction, and uniform shrinkage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

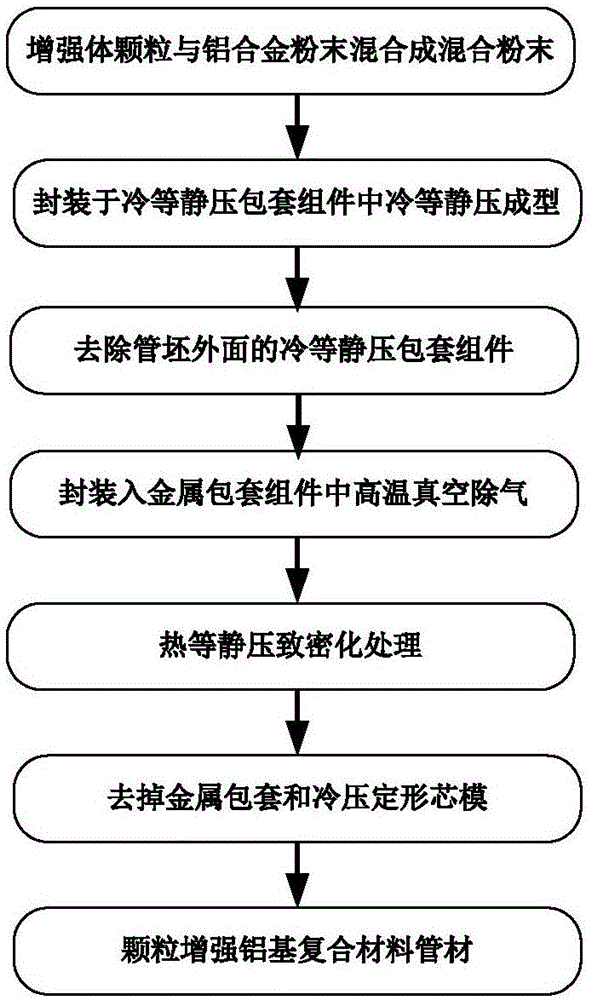

[0032] The composition of the composite pipe prepared in this example is 15vol.% SiCp / 2009Al, and the size of the pipe is 1000mm in outer diameter, 150mm in wall thickness, and 800mm in length.

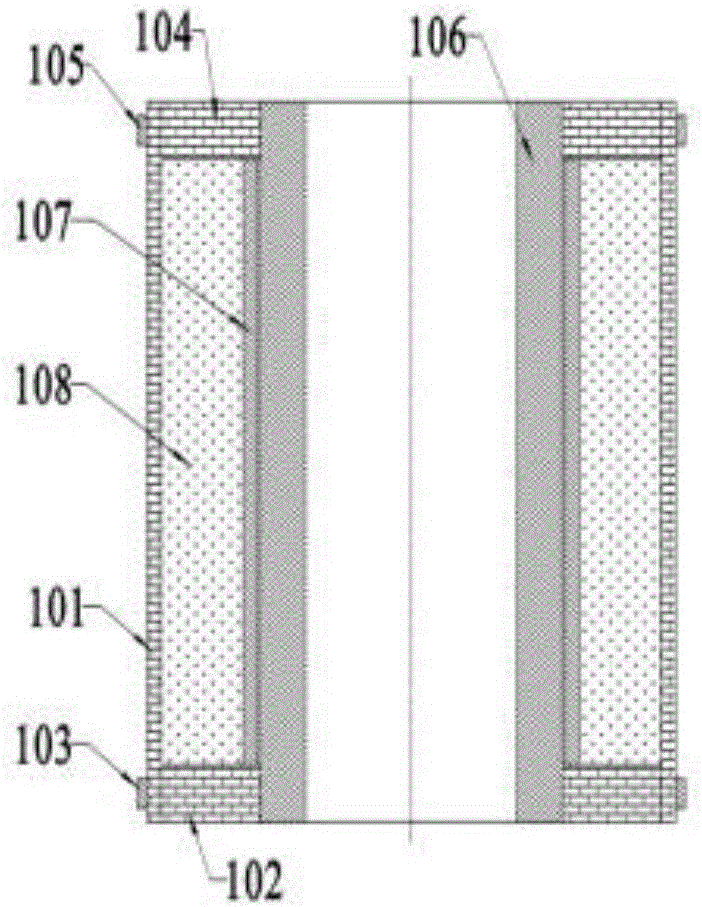

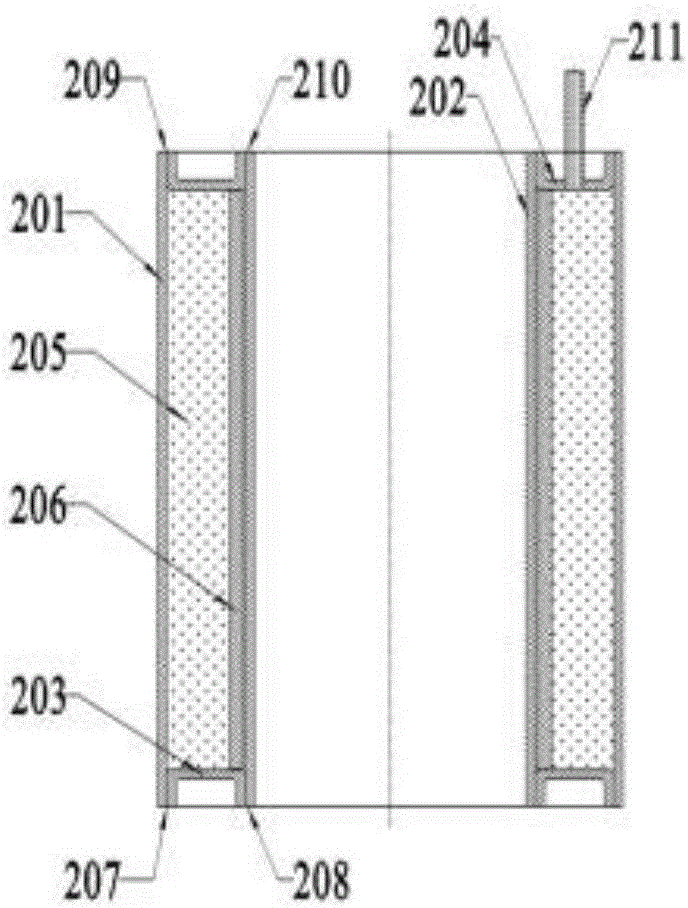

[0033] according to figure 1 The preparation method shown: (1) uniformly mix silicon carbide powder and 2009Al alloy powder according to the volume ratio of 15:75, and the average particle size of silicon carbide powder is d 0.5 5.5μm, the average particle size of 2009Al powder d 0.5The mixing steel ball is made of bearing stainless steel, the specification is Φ20mm, the weight ratio of the ball to material is 5:1, the speed of the mixer is 30r / min, and the mixing time is 48 hours; (2) each cold isostatic pressing package assembly Sequential assembly, the material of the cold-pressed and shaped mandrel is stainless steel, with an outer diameter of 690mm, a wall thickness of 10mm, and a length of 820mm; the material of the cold-pressed sealed mandrel is made of No. 45 steel, with an o...

Embodiment 2

[0035] The composition of the composite pipe prepared in this example is 5vol.% Al 2 o 3 / 2024Al, the pipe size is 500mm in outer diameter, 80mm in wall thickness, and 500mm in length.

[0036] according to figure 1 The preparation method shown: (1) Al 2 o 3 Powder and 2024Al alloy powder are evenly mixed according to the volume ratio of 5:95, Al 2 o 3 Powder average particle size d 0.5 2μm, the average particle size of 2024Al powder d 0.5 5 μm; the material of the mixing steel ball is bearing stainless steel, the specification is Φ10mm, the weight ratio of the ball to material is 8:1, the speed of the mixer is 40r / min, and the mixing time is 48 hours; (2) each cold isostatic pressing package assembly Sequential assembly, the material of the cold-pressed and shaped mandrel is stainless steel, with an outer diameter of 330mm, a wall thickness of 6mm, and a length of 520mm; the material of the cold-pressed sealed mandrel is made of No. 45 steel, with an outer diameter of ...

Embodiment 3

[0038] The composition of the composite pipe prepared in this example is 10vol.% B 4 C / 6061Al, the pipe size is 200mm in outer diameter, 20mm in wall thickness, and 1500mm in length.

[0039] according to figure 1 The preparation method shown: (1) with B 4 C powder and 6061Al alloy powder are uniformly mixed according to the volume ratio of 10:90, B 4 C powder average particle size d 0.5 20μm, 6061Al powder average particle size d 0.5 The mixing steel ball is made of bearing stainless steel, the specification is Φ15mm, the weight ratio of the ball to material is 15:1, the speed of the mixer is 60r / min, and the mixing time is 24 hours; (2) each cold isostatic pressing package assembly Sequential assembly, the material of the cold-pressed and shaped mandrel is stainless steel, with an outer diameter of 156mm, a wall thickness of 4mm, and a length of 1520mm; the material of the cold-pressed sealed mandrel is made of No. 45 steel, with an outer diameter of 147mm and a wall thi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com