Preparation method of wear-resistant super-hydrophobic metal surface

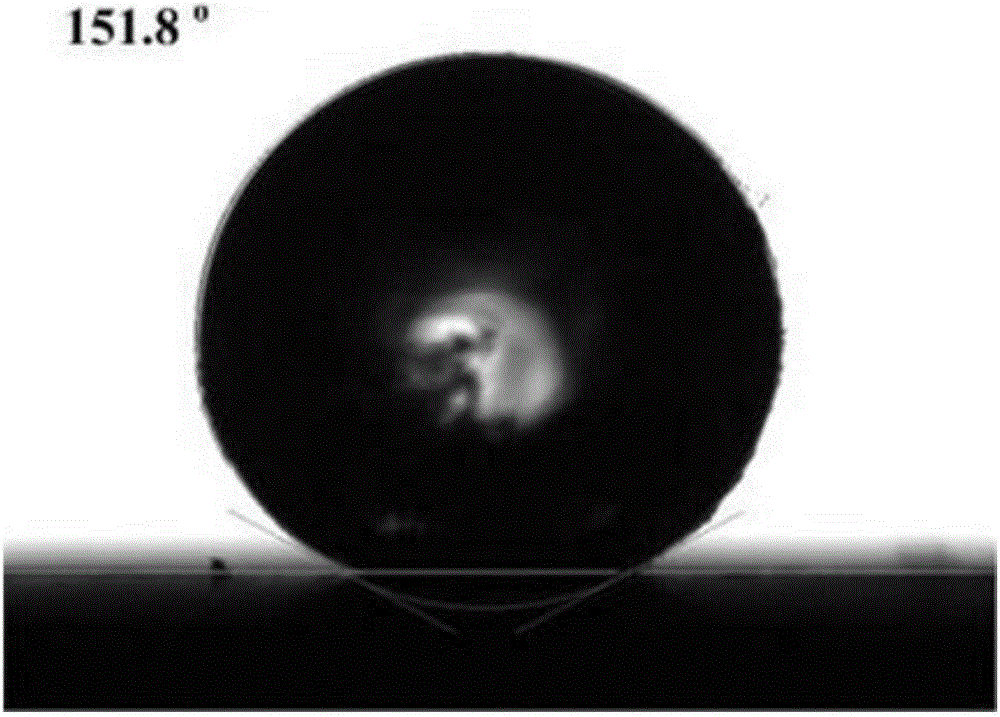

A metal surface, super-hydrophobic technology, applied in metal processing equipment, devices for coating liquid on the surface, special surfaces, etc., can solve the problems of low efficiency, poor applicability of different metal substrates, high cost, etc., to achieve improved durability and effective Facilitate large-scale application and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

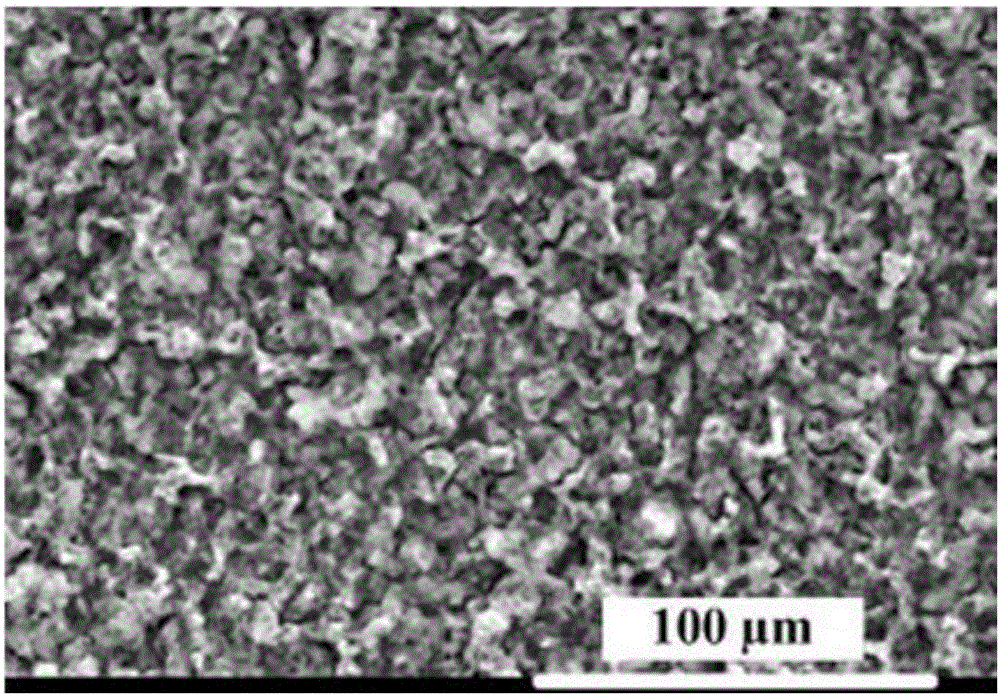

[0031] The preparation method of the wear-resistant superhydrophobic metal surface of the present invention is specifically implemented according to the following steps:

[0032] Step 1, preparing an ordered microstructure array on the surface of the metal substrate by mask micro-electrolytic machining;

[0033] The specific process is:

[0034] Step 1.1, metal substrate treatment: Polish the surface of the metal substrate with sandpaper to make the metal substrate roughness Ra≤0.3, then wash it with acetone, alcohol and deionized water in sequence, dry it with nitrogen, and then dry it for use;

[0035] Step 1.2, preparation of a patterned flexible insulating masking film: the flexible insulating film is made of a polyimide film with a thickness of 0.05-0.2 mm, and the flexible insulating film is first cleaned with alcohol and deionized water and dried with compressed air; using an ultraviolet laser The marking machine processes micro-hole arrays on the flexible insulating f...

Embodiment 1

[0054] Step 1, preparing an ordered microstructure array on the surface of the metal substrate by mask micro-electrolytic machining;

[0055] The specific process is:

[0056] Step 1.1, metal substrate treatment: Polish the surface of the metal substrate with sandpaper to make the metal substrate roughness Ra≤0.3, then wash it with acetone, alcohol and deionized water in sequence, dry it with nitrogen, and then dry it for use;

[0057] Step 1.2, preparation of a patterned flexible insulating masking film: the flexible insulating film is made of a polyimide film with a thickness of 0.05 mm, and the flexible insulating film is first cleaned with alcohol and deionized water and dried with compressed air; marking with an ultraviolet laser The machine processes the micro-hole array on the flexible insulating film, the process parameters: speed: 10mm / s, laser effective power: 3W, frequency: 20KHz;

[0058] Step 1.3, mask micro-electrolytic machining to prepare an ordered microstruc...

Embodiment 2

[0064] Step 1, preparing an ordered microstructure array on the surface of the metal substrate by mask micro-electrolytic machining;

[0065] The specific process is:

[0066] Step 1.1, metal substrate treatment: Polish the surface of the metal substrate with sandpaper to make the metal substrate roughness Ra≤0.3, then wash it with acetone, alcohol and deionized water in sequence, dry it with nitrogen, and then dry it for use;

[0067] Step 1.2, preparation of a patterned flexible insulating masking film: the flexible insulating film is made of a polyimide film with a thickness of 0.1 mm, and the flexible insulating film is first cleaned with alcohol and deionized water and dried with compressed air; marking with an ultraviolet laser The machine processes the micro-hole array on the flexible insulating film, the process parameters: speed: 20mm / s, laser effective power: 2W, frequency: 20KHz;

[0068] Step 1.3, mask micro-electrolytic machining to prepare an ordered microstruct...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com