Complexing type macroporous ion exchange resin and preparation method thereof

An ion exchange resin and exchange resin technology, applied in ion exchange of chelates, ion exchange, chemical instruments and methods, etc., can solve problems such as poor results, reduce repeated investment, simplify the process, and realize small batches Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

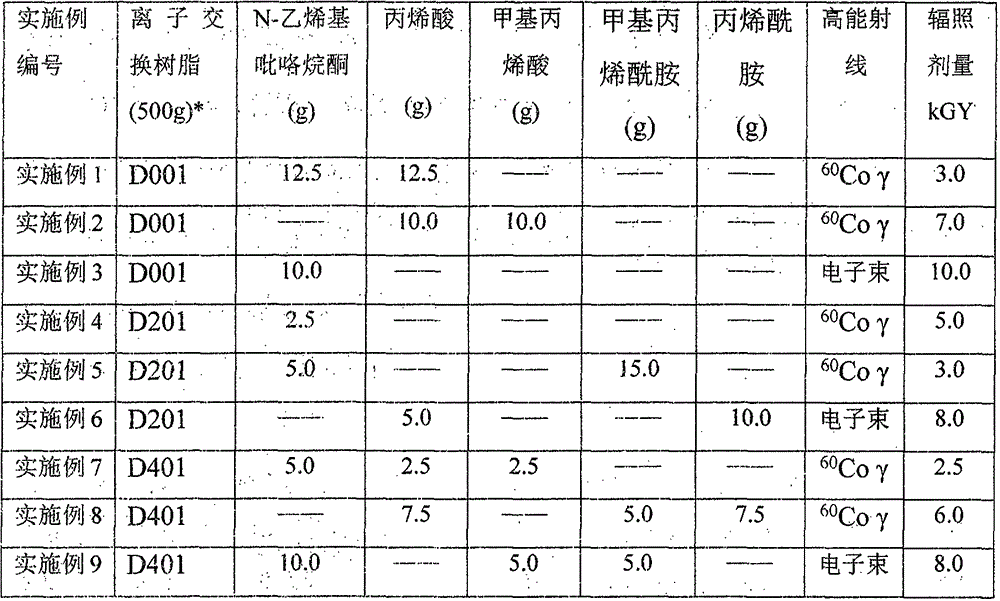

Examples

Embodiment 1

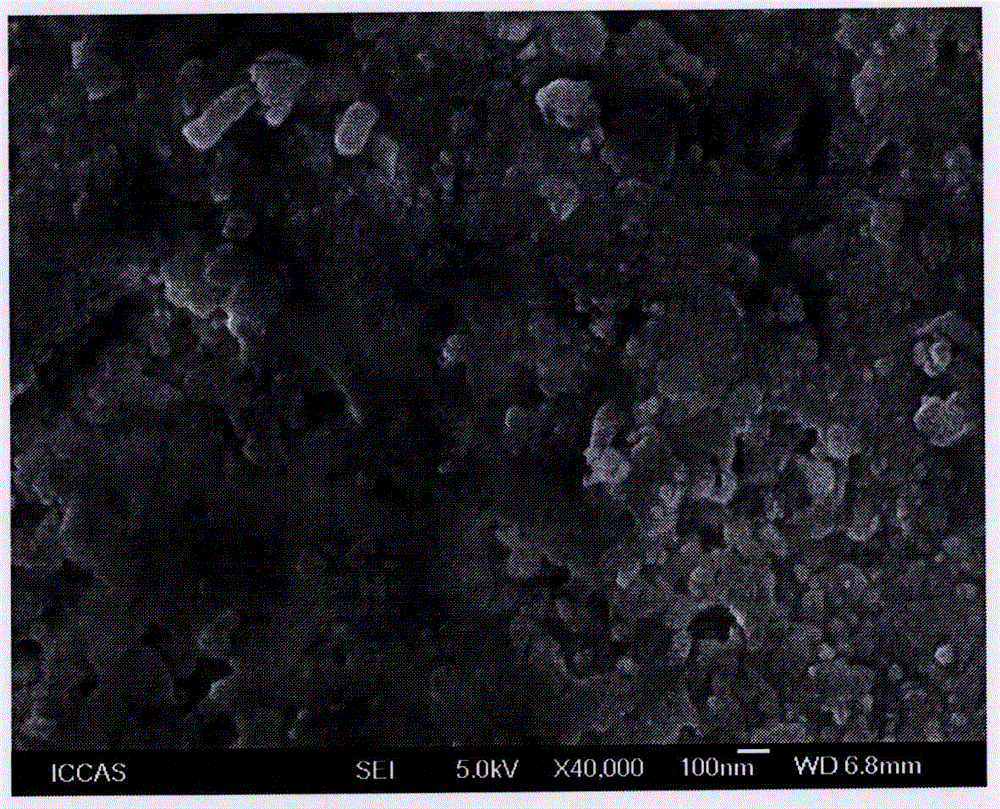

[0040] The complex type macroporous ion exchange resin prepared in Examples 1-3 has a good trapping effect on nanometer copper; figure 1 For the prepared complex type macroporous ion exchange resin of embodiment 1, after processing the filtrate of preparing nano-copper by hydrazine hydrate reduction, the resin is cleaned with dehydrated alcohol, vacuum-dried, field emission electron scanning microscopic analysis photo. from figure 1It can be seen that a large number of nano-copper particles are enriched on the surface of the resin.

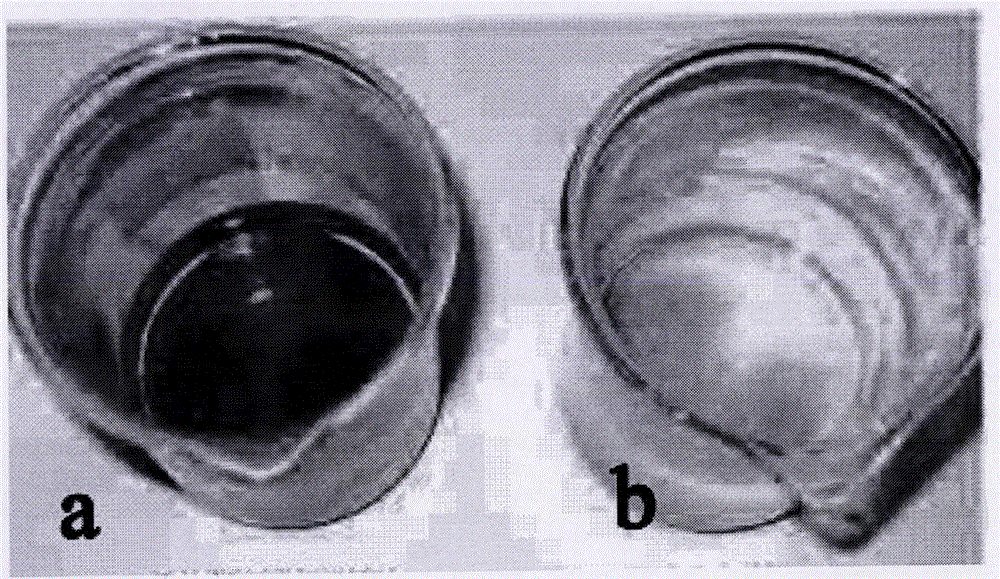

[0041] from figure 2 It can be seen that the complexed macroporous ion-exchange resin prepared in Example 1 turns reddish-brown in color after treating the filtrate prepared by reduction of hydrazine hydrate to prepare nano-copper, see figure 2 (a); while the resin before adsorption is light yellow, see figure 2 (b); The complex type macroporous ion exchange resin has a good trapping effect on the copper particles in the filtrate for prepari...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com