Preparation method and application of single-section solar light collector based on white light carbon dots

A technology of solar concentrators and carbon dots, applied in chemical instruments and methods, luminescent materials, photovoltaic power generation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

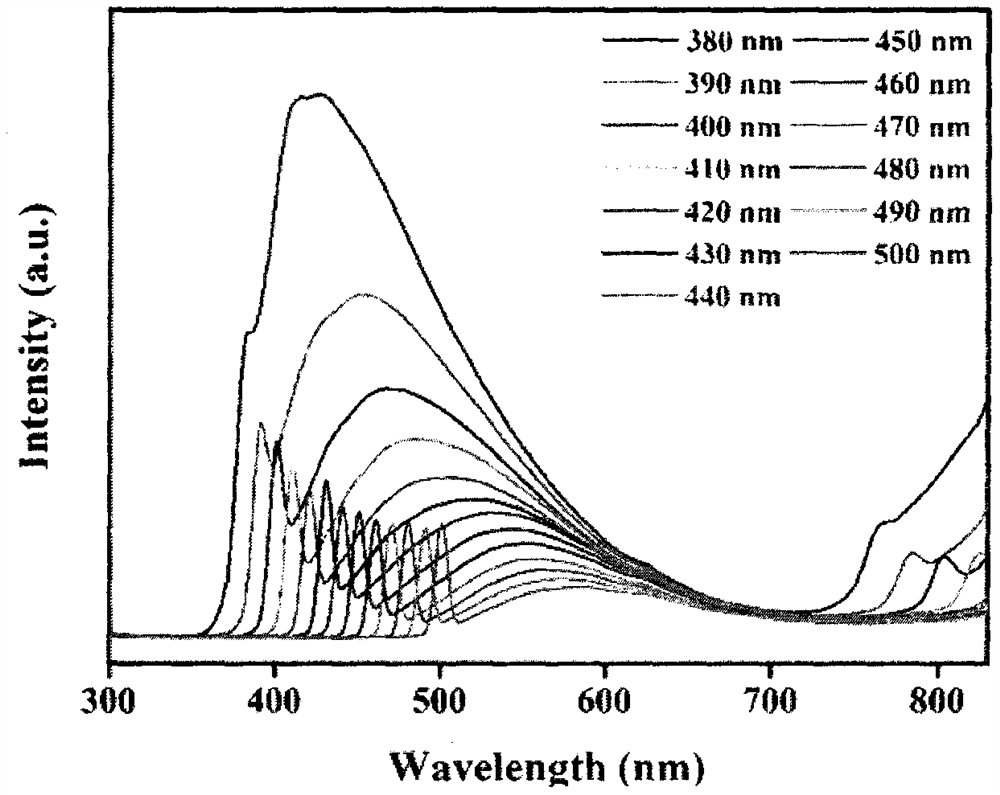

Image

Examples

Embodiment 1

[0015] The preparation of white light carbon dots comprises the following steps:

[0016] (1) The preparation steps of the single-section light collector based on white light carbon dots are: weigh catechol with a mass ratio of 5:1 to 1:5, dissolve it in ethanol, and obtain a uniform mixed solution by ultrasonication for a certain period of time; Pour the mixed solution into a 50mL reactor and react at 150-200°C for 6-10h; then centrifuge the resulting carbon dot stock solution for 8min to separate and remove large particles of impurities, and finally store the synthesized carbon dot stock solution in a refrigerator at 4°C spare.

[0017] (2) The prepared carbon dots have a high fluorescence quantum yield of 57%.

Embodiment 2

[0019] The preparation of a single-section solar concentrator with a carbon dot concentration of 0.8wt% comprises the following steps:

[0020] (1) embedding an appropriate amount of carbon dots in a polymer (polyvinylpyrrolidone, polymethylmethacrylate) matrix to form a colloidal solution with a concentration of 0.8wt%;

[0021] (2) Spin-coat at a low speed of 500-1500rpm / s for 10-20s to spread the carbon dots / polymer solution evenly on the high-transmission glass bottom, and set the high-speed condition to 2000-3000rpm / s for 20- 30s to obtain a single-section solar concentrator with uniformity and high transmittance;

[0022] (3) Couple the edge of the solar concentrator to a commercial monocrystalline silicon cell, and test and calculate various photovoltaic values under simulated sunlight irradiation; Jcs, Voc, FF, PCE, η opt , C (concentration factor) are: 12.62mA / cm 2 , 0.49V, 68.9%, 4.26%, 5.36%, 0.34.

Embodiment 3

[0024] The preparation of a single-section solar concentrator with a carbon dot concentration of 1.0wt% comprises the following steps:

[0025] (1) Embedding an appropriate amount of carbon dots into a polymer (polyvinylpyrrolidone, polymethylmethacrylate) matrix to form a colloidal solution with a concentration of 1.0wt%;

[0026] (2) Spin-coat at a low speed of 500-1500rpm / s for 10-20s to spread the carbon dots / polymer solution evenly on the high-transmission glass bottom, and set the high-speed condition to 2000-3000rpm / s for 20- 30s to obtain a single-section solar concentrator with uniformity and high transmittance;

[0027] (3) Couple the edge of the solar concentrator to a commercial monocrystalline silicon cell, and test and calculate various photovoltaic values under simulated sunlight irradiation; Jcs, Voc, FF, PCE, η opt , C (concentration factor) are: 13.88mA / cm 2 , 0.49V, 66.2%, 4.5%, 5.89%, 0.37.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com