Preparation method for mesoporous compound film

A composite membrane and mesoporous technology, applied in the field of materials, can solve the problems that silicon oxide is easy to fall off and cannot be applied, and achieves the effect of simple preparation process and environmental friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The embodiment of the present invention discloses a method for preparing a mesoporous composite membrane, which includes the following steps: under the action of a catalyst, carry out an alcoholysis reaction of a precursor compound and a structure-directing agent in ethanol to obtain a sol, and the precursor compound is selected from From one or more of silicon source compounds, titanium source compounds, zinc source compounds, tin source compounds and niobium source compounds, the structure directing agent is selected from polyethylene oxide-polypropylene oxide-polyethylene oxide One or more of alkane triblock copolymer, cetyltrimethylammonium bromide and sodium lauryl sulfate; the porous membrane is surface treated, and then soaked in the sol for 2 to 24 hours ; Dry the soaked porous membrane at room temperature and complete the sol-gel process, then wash and dry to obtain the mesoporous composite membrane.

[0031] In the sol preparation step, the catalyst is prefera...

Embodiment 1

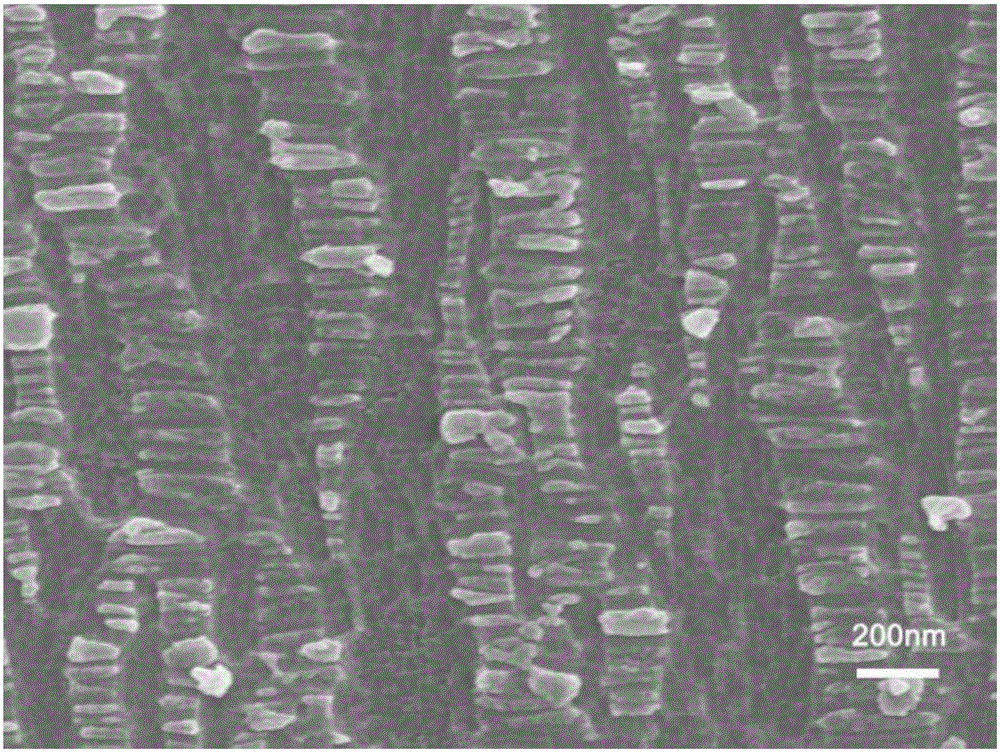

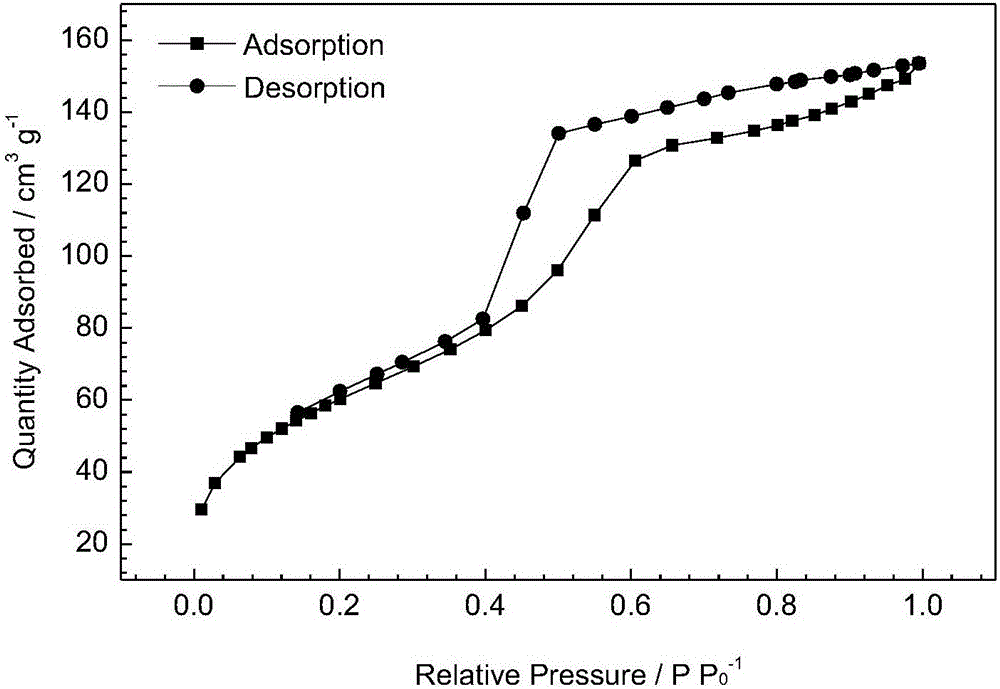

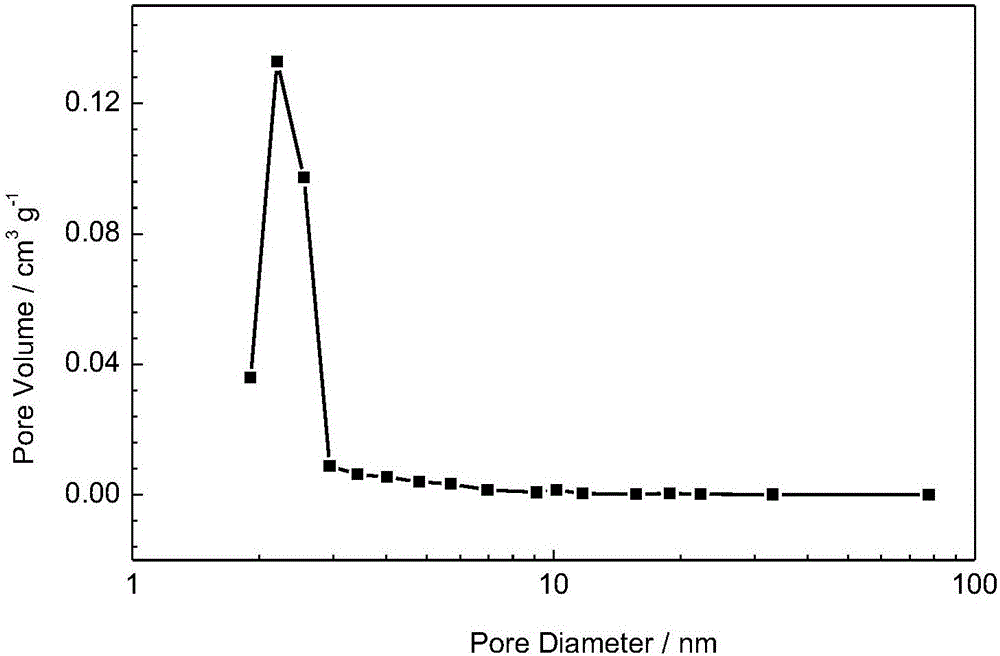

[0044] Soak a uniaxially stretched PP porous membrane with a thickness of 25 μm (pore size about 40nm×200nm) in a large amount of absolute ethanol and ultrasonically clean it for 0.5h, and dry it to prevent dust; place the cleaned and dried porous PP membrane in a plasma Processed in the body apparatus for 20s, then sealed in a ziplock bag. Dissolve 2.0g of F127 in 6.0g of ethanol, add 1.5g of 0.2mol L~1 hydrochloric acid solution while stirring, add 6.0g of TEOS into the mixture, and stir at room temperature for 2h to obtain a colorless and transparent silica sol . The treated PP porous membrane was immersed in the sol for 24 h until the membrane was completely permeated and became transparent. Take out the sol-soaked film, and let it dry naturally in the air for 48 hours at a relative humidity of 60-80%, so that the sol-gel process of silica can fully proceed, and carefully remove the remaining silica on the surface of the completely dried film. peeling off, and finally wa...

Embodiment 2

[0047] Soak a uniaxially stretched PP porous membrane with a thickness of 25 μm (pore size about 40nm×200nm) in a large amount of absolute ethanol and ultrasonically clean it for 0.5h, and dry it to prevent dust; take 50mL of 0.1M Tris(Hydroxymethyl)aminomethane solution , add 14.7mL of 0.1M HCl, adjust the pH value to 8.5, dilute to 100mL, and obtain 0.05M Tris·HCl buffer solution. Take 50 mL of 0.05M Tris·HCl buffer and dilute to 250 mL to obtain 0.01M buffer. Dissolve 0.5g Dopamine in 250mL 0.01M Tris HCl buffer solution, then soak the ethanol-soaked PP membrane in the mixed solution, ultrasonically treat it for 0.5h, let it stand for 12h, and finally take out the PP membrane and wash it with a large amount of deionized water and Wash and dry with absolute ethanol; dissolve 2.0g F127 in 6.0g ethanol, add 1.5g of 0.2mol L~1 hydrochloric acid solution while stirring, add 6.0g TEOS to the mixture, stir at room temperature for 2h, and obtain transparent silica sol. The untrea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Mesopore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com