Lithium-rich ternary composite material and preparation method thereof

A technology of composite materials and ternary materials, which is applied in the field of lithium-rich ternary composite materials and their preparation, can solve the problems of ternary material energy density and cycle performance that cannot meet high specific energy density, and achieve improved transmission rate and rate performance , reduce the probability of lithium precipitation, improve the effect of rate performance and safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

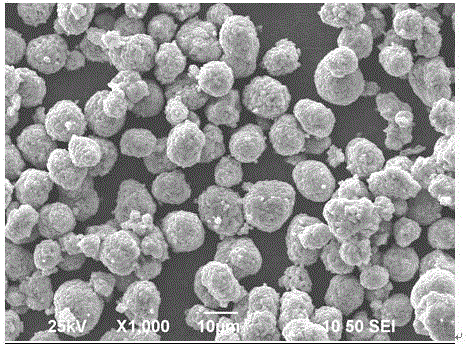

Image

Examples

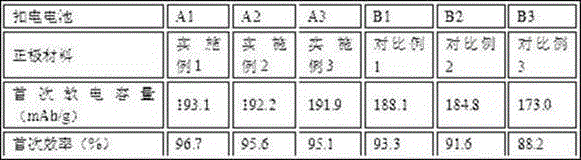

Embodiment 1

[0020] 1) First, weigh 95g of high-molecular polymer polypropylene carbonate and dissolve it in 500ml of carbon tetrachloride, then add 5g of lithium powder (particle size 0.2μm), and stir evenly to obtain lithium powder-coated colloid A; At the same time, weigh 30g of polyvinylidene fluoride and add it to 500ml of N-methylpyrrolidone, dissolve evenly and then add 40g of graphene to disperse evenly at high speed, then add 30g of lithium metaaluminate and disperse evenly to obtain metaaluminate Lithium mixture B;

[0021] 2) Then weigh 120g of LiNi 0.6 co 0.2 mn 0.2 o 2 Ternary material (manufacturer: Henan Kelong New Energy Co., Ltd., model: KL206) is added to colloid A, stirred evenly, filtered, and vacuum dried at 80°C to obtain a ternary material / lithium powder complex, and then added to lithium metaaluminate In the mixed liquid B, stir evenly, filter, heat up to 150°C at a heating rate of 3°C / min, keep it warm for 2 hours, and naturally cool down to room temperature to...

Embodiment 2

[0023] 1) First weigh 90g of polymer polymethylsiloxane and dissolve it in 500ml of carbon tetrachloride, then add 10g of lithium powder (particle size is 0.1μm), and stir evenly to obtain lithium powder coated colloid A; At the same time, weigh 20g of polyvinylidene fluoride and add it to 500ml of N-methylpyrrolidone, dissolve evenly and then add 40g of graphene to disperse evenly at high speed, then add 40g of lithium metaaluminate and disperse evenly to obtain partial Lithium aluminate mixed solution B;

[0024] 2) Then weigh 100g of LiNi 0.6 co 0.2 mn 0.2 o 2 Ternary material (manufacturer: Henan Kelong New Energy Co., Ltd., model: KL206) is added to colloid A, stirred evenly, filtered, and vacuum dried at 80°C to obtain a ternary material / lithium powder complex, and then added to lithium metaaluminate In the mixed solution B, stir evenly, filter, heat up to 180°C at a heating rate of 1°C / min, keep it warm for 3 hours, and cool down to room temperature naturally to obt...

Embodiment 3

[0026] 1) First weigh 99g of polymethyl acrylate polymer and dissolve it in 500ml of carbon tetrachloride, then add 1g of lithium powder (with a particle size of 0.5μm), and stir evenly to obtain lithium powder-coated colloid A; At the same time, weigh 40g of polyvinylidene fluoride and add it to 500ml of N-methylpyrrolidone, dissolve evenly and then add 30g of graphene to disperse evenly at high speed, then add 30g of lithium metaaluminate and disperse evenly to obtain metaaluminate Lithium mixture B;

[0027] 2) Then weigh 150g of LiNi 0.6 co 0.2 mn 0.2 o 2 Ternary material (manufacturer: Henan Kelong New Energy Co., Ltd., model: KL206) is added to colloid A, stirred evenly, filtered, and vacuum dried at 80°C to obtain a ternary material / lithium powder complex, and then added to lithium metaaluminate In the mixed solution B, stir evenly, filter, raise the temperature to 180°C at a heating rate of 5°C / min, keep it warm for 1h, and naturally cool down to room temperature t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com