A composite lithium-rich manganese-based positive electrode material and preparation method thereof

A cathode material, lithium-rich manganese-based technology, applied in battery electrodes, structural parts, electrical components, etc., can solve problems such as poor conductivity and unstable coating structure, and achieve improved electrochemical performance, improved cycle stability, The effect of high rate charge and discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

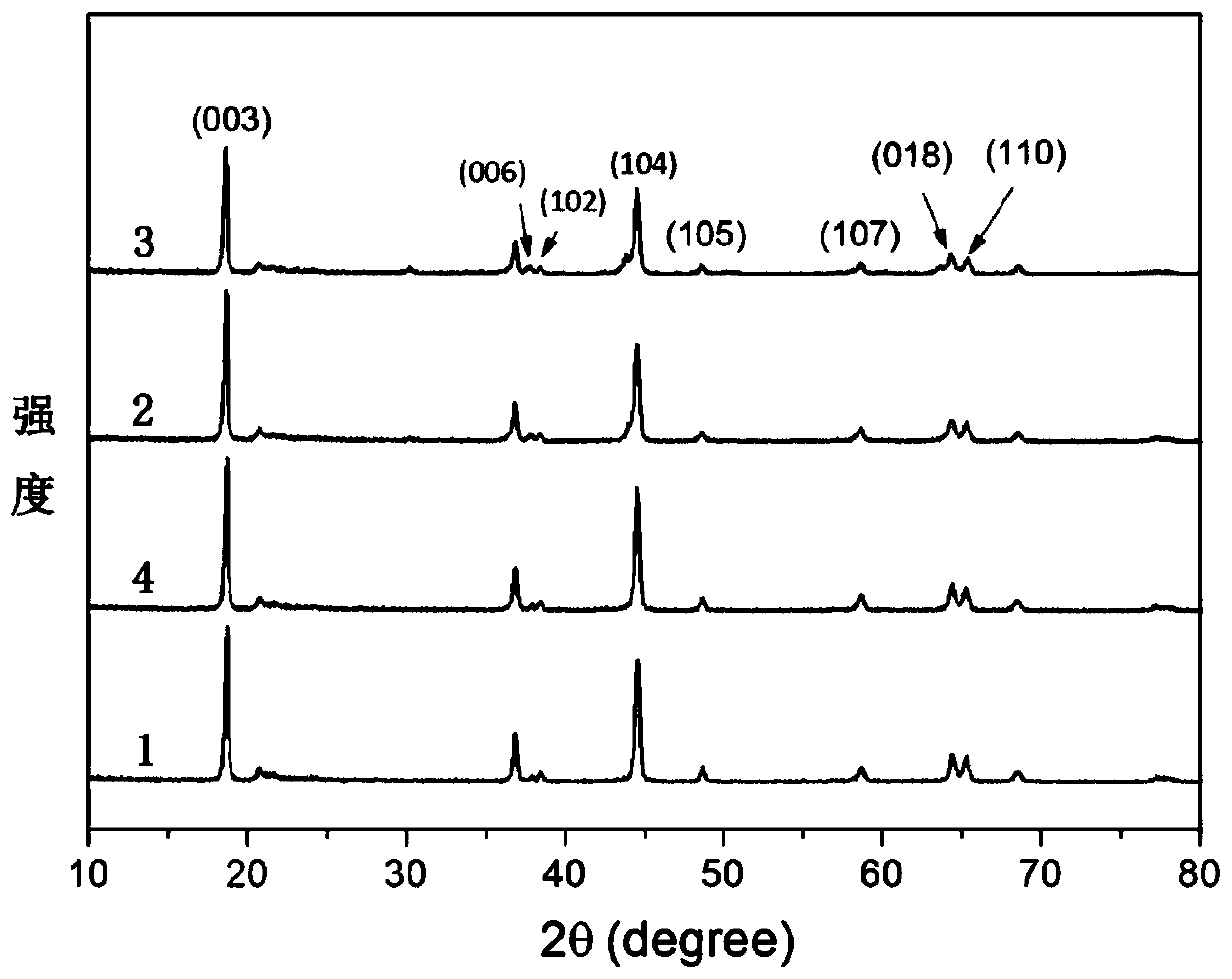

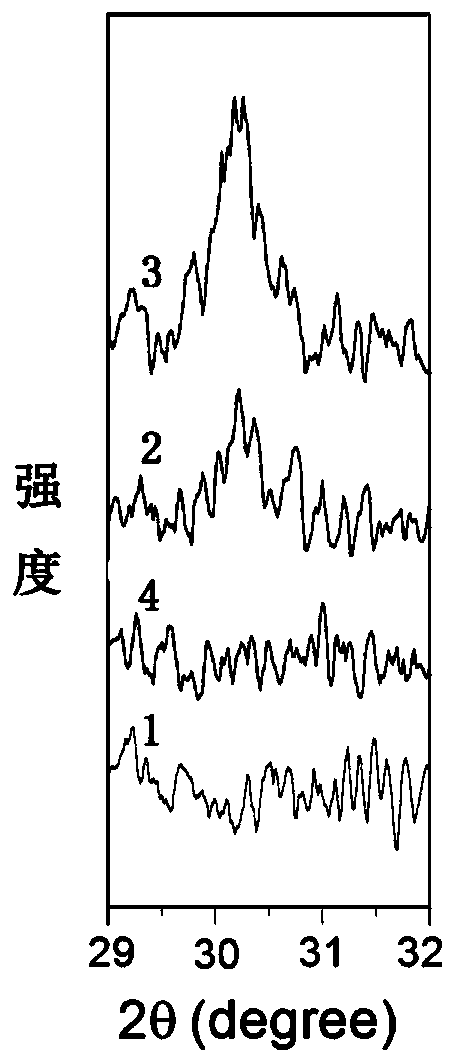

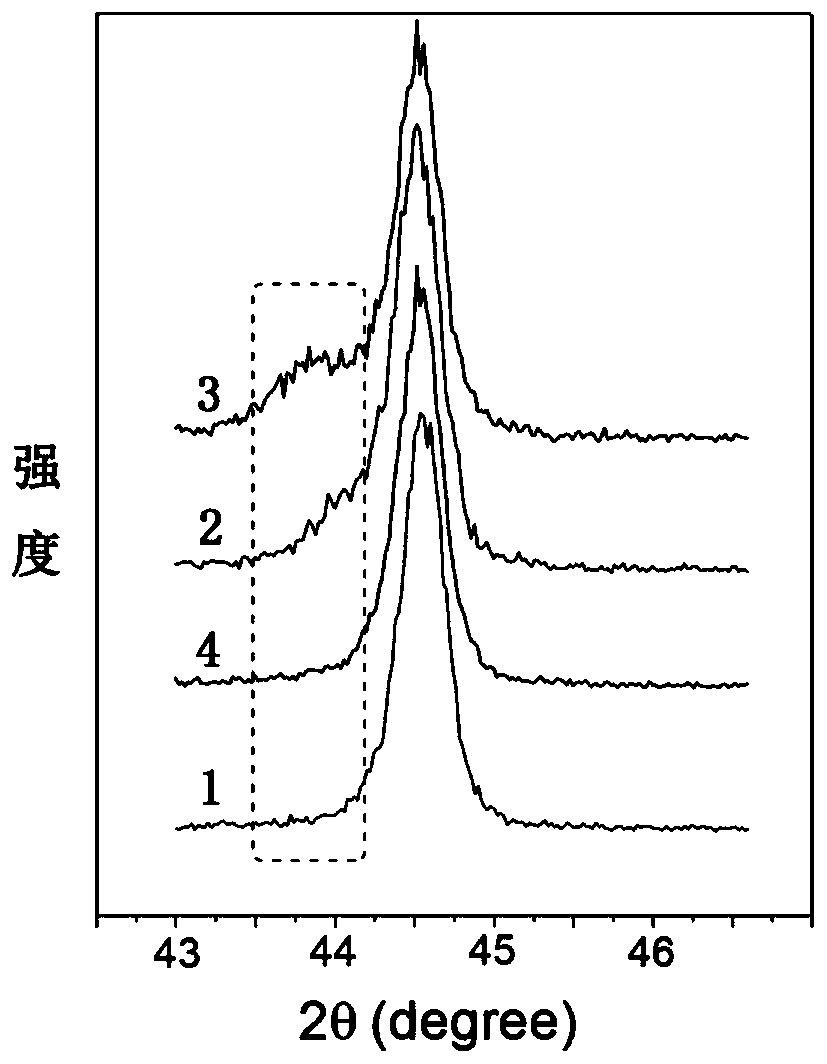

[0048] Li 1.2 mn 0.6 Ni 0.2 o 2 The mass of NaZr 2 (PO 4 ) 3 When the mass ratio of the coating layer is 1:0.03, the preparation steps of the composite lithium-rich manganese-based positive electrode material are as follows:

[0049] Step 1. Dissolve 0.0053g of sodium nitrate in 2mL of deionized water, stir at 50°C and 500rpm for 0.5h to obtain a sodium salt solution; dissolve 0.0525g of zirconium nitrate pentahydrate in 3mL of deionized water, stir at 50°C and Stir at a stirring speed of 500rpm for 0.5h to obtain a zirconium salt solution; dissolve 0.0215g of ammonium dihydrogen phosphate in 5mL of deionized water, stir at 50°C and a stirring speed of 500rpm for 0.5h to obtain a phosphate solution; Dissolve 1,300,000 polyvinylpyrrolidone in 10 mL of deionized water, and stir for 6 hours at 30°C and a stirring speed of 500 rpm to obtain a complexing agent solution;

[0050] Step 2. Add the sodium salt solution, zirconium salt solution and phosphate solution prepared in ...

Embodiment 2

[0055] Li 1.2 mn 0.6 Ni 0.2 o 2 The mass of NaZr 2 (PO 4 ) 3 When the mass ratio of the coating layer is 1:0.05, the preparation steps of the composite lithium-rich manganese-based positive electrode material are as follows:

[0056] Step 1. Dissolve 0.0088g of sodium nitrate in 2mL of deionized water, stir at 50°C and 500rpm for 0.5h to obtain a sodium salt solution; dissolve 0.0876g of zirconium nitrate pentahydrate in 3mL of deionized water, stir at 50°C and Stir for 0.5 h at a stirring speed of 500 rpm to obtain a zirconium salt solution; dissolve 0.0357 g of ammonium dihydrogen phosphate in 5 mL of deionized water, and stir for 0.5 h at 50° C. and a stirring speed of 500 rpm to obtain a phosphate solution; Dissolve 1,300,000 g of polyvinylpyrrolidone in 10 mL of deionized water, and stir for 7 hours at 30°C and a stirring speed of 500 rpm to obtain a complexing agent solution;

[0057] Step 2. Add the sodium salt solution, zirconium salt solution and phosphate solu...

Embodiment 3

[0062] Li 1.2 mn 0.6 Ni 0.2 o 2 The mass of NaZr 2 (PO 4 ) 3 When the mass ratio of the coating layer is 1:0.07, the preparation steps of the composite lithium-rich manganese-based positive electrode material are as follows:

[0063] Step 1. Dissolve 0.0124g of sodium nitrate in 2mL of deionized water, stir at 50°C and 500rpm for 0.5h to obtain a sodium salt solution; dissolve 0.1225g of zirconium nitrate pentahydrate in 3mL of deionized water, stir at 50°C and Stir at a stirring speed of 500rpm for 0.5h to obtain a zirconium salt solution; dissolve 0.0501g of ammonium dihydrogen phosphate in 5mL of deionized water, and stir at 50°C for 1h at a stirring speed of 500rpm to obtain a phosphate solution; the average molecular mass of 1.4g is Dissolve 1,300,000 g of polyvinylpyrrolidone in 15 mL of deionized water, and stir for 7 hours at 30°C and a stirring speed of 500 rpm to obtain a complexing agent solution;

[0064] Step 2. Add the sodium salt solution, zirconium salt ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com