Tin-based perovskite thin film, preparation method of film and solar cell device of film

A perovskite and thin film technology, which is applied in the field of tin-based perovskite thin films, preparation methods and solar cell devices, can solve the problems of easy oxidation of tin elements and high intrinsic carrier concentration, and achieve improved life and good performance , high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

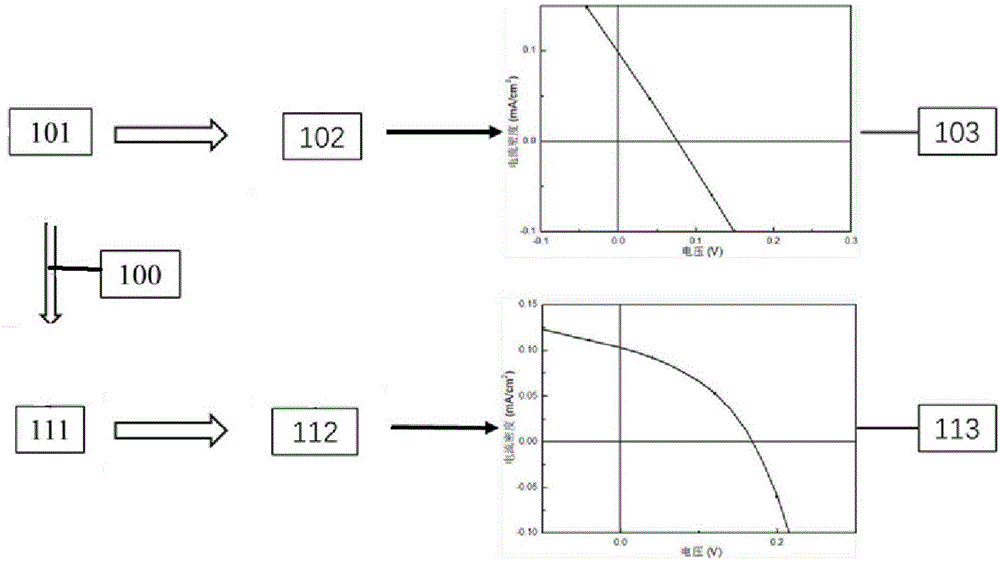

[0035] This scheme firstly provides a kind of preparation method of tin-based perovskite film, and this method comprises the following steps:

[0036] Step A: preparing a precursor solution; the precursor solution is obtained by adding perovskite and phosphates into the solution, and the solution is a mixture of one or both of DMF and DMSO; the perovskite The species is tin-based organometallic halide perovskite CH 3 NH 3 SnA x B 3-x and tin-based inorganic perovskite material CsSnA x B 3-x One or more of them, where A, B=Cl, Br or I. The concentration of the perovskite is 0.7-1.5M. The phosphate esters are triphenyl phosphate, and the concentration of the triphenyl phosphate is 0.01-1.0 M. These materials and concentrations enable perovskite films with better properties.

[0037]Phosphate esters are currently mainly used as flame retardant plasticizers for PVC. The main varieties are tricresyl phosphate (TCP), triphenyl phosphate (TPP), diphenyl octyl phosphate (DPOP)...

example 1

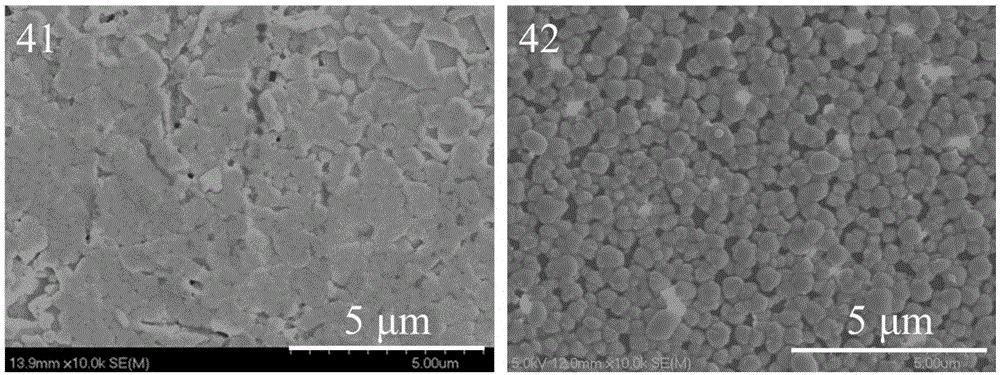

[0058] (1) TPPi, SnI 2 and CsI were added to DMF:DMSO (5:1) mixed solvent according to the molar ratio of 0.6:1:1 (SnI 2 concentration of 1M), and the solution was stirred at 70 °C for 12 h.

[0059] (2) Ultrasonic cleaning of ITO in acetone, ITO cleaning solution, deionized water and isopropanol for 10 min, drying and using UV-O 3 Washing machine for 30 min. Deposit PEDOT:PSS on the surface of ITO by spin coating at 3500 rpm for 30 s, N 2 treated in a glove box at 130 °C for 1 h. Among them, ITO (Indium-Tin Oxide) refers to indium tin oxide, that is, indium tin oxide transparent conductive glass

[0060] (3) The perovskite solution configured in (1) was dropped onto the surface of PEDOT:PSS, and spin-coated at 3000 rpm for 30 s to obtain a perovskite film; the film was finally heated on a heating platform at 90 °C for 10 min.

[0061] (4) Deposit the PCBM film on the perovskite film by spin-coating at 1500 rpm for 30 s. last at 10 -4 A 100 nm silver electrode was ther...

example 2

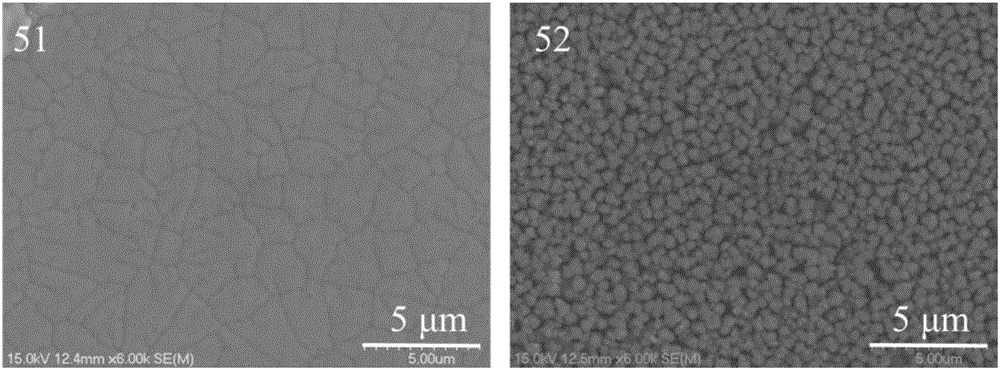

[0068] (1) TPPi, SnI 2 and CsI were added to DMF:DMSO (5:1) mixed solvent according to the molar ratio of 0.6:1:1 (SnI 2 concentration of 1M), and the solution was stirred at 70 °C for 12 h.

[0069] (2) Ti(OBu) 4 , absolute ethanol and glacial acetic acid were mixed in a molar ratio of 1:16:1.5, stirred for 1 h to form a solution A; the molar ratio was 1:4:0.075 distilled water, absolute ethanol and nitric acid were mixed, stirred for 1 h to form a B solution; The absolute ethanol of solution A is twice that of solution B. After solution B was added dropwise to solution A, stirring was continued for 2 h to form a clear and transparent TiO 2 Precursor sol C.

[0070] (3) The FTO was ultrasonically cleaned in acetone, ITO cleaning solution, deionized water and isopropanol for 10 min, and then treated with a plasma cleaner for 3 min after drying. TiO prepared in (2) 2 Precursor sol C was deposited on the surface of FTO by spin coating at 6000 rpm for 60 s, and finally sint...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com