Control method of rapid high-precision cold mirror type dew-point instrument

A control method and high-precision technology, applied to controllers with specific characteristics, electric controllers, moisture content of materials, etc., can solve problems such as failure to reach a stable state, no reading value, and extended measurement time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Further illustrate the present invention below in conjunction with accompanying drawing and specific embodiment

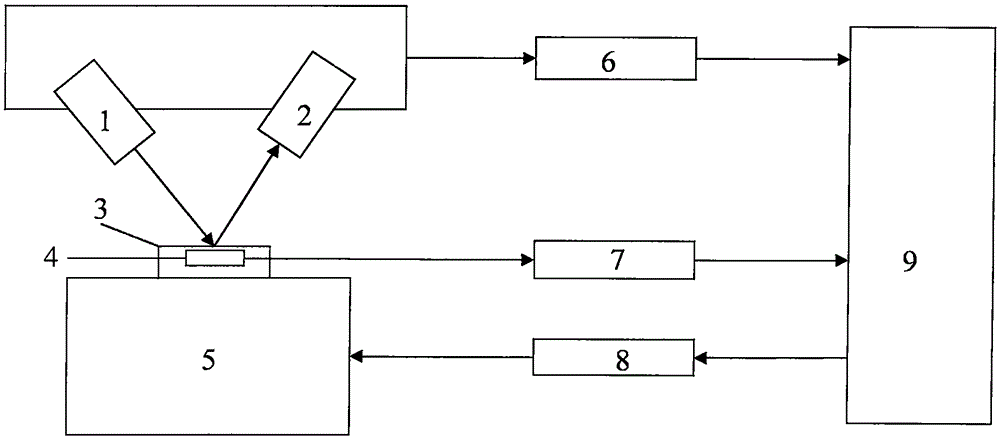

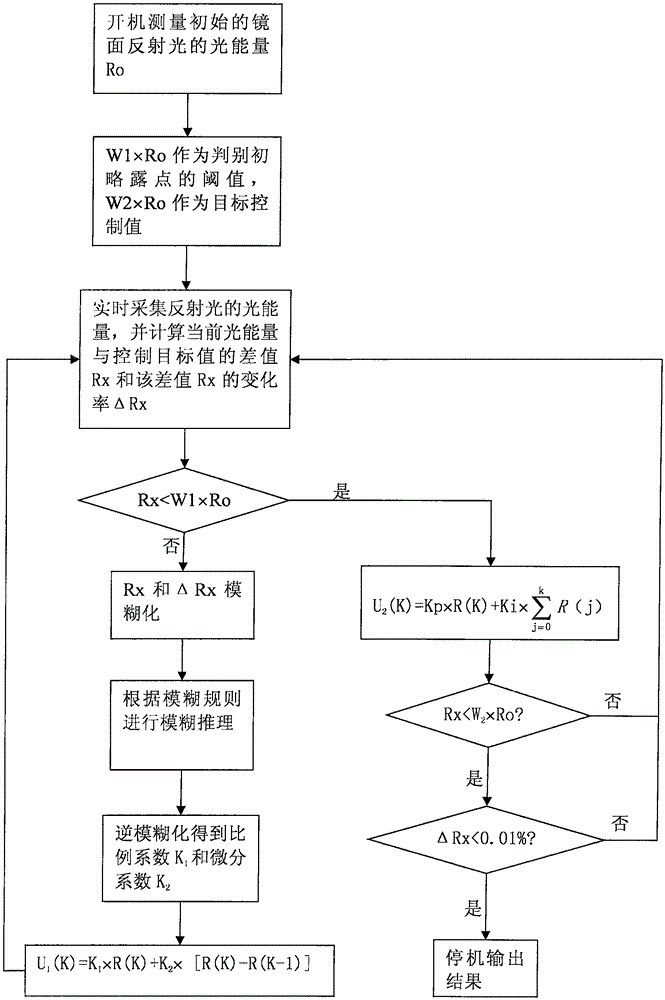

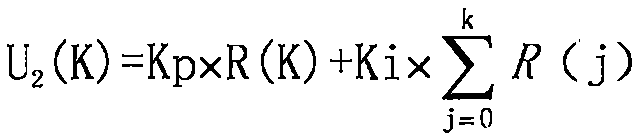

[0020] The fast and high-precision chilled mirror dew point meter provided by the present invention has a structure as follows: figure 1 shown. Including dew point chamber, photoelectric detection system, temperature measurement system, refrigeration system, single-chip microcomputer control processing system, etc. The dew point chamber includes a photoelectric detection unit composed of a light emitting diode 1, a photodiode 2 and a mirror 3, a platinum resistor 4 and a refrigeration unit 5; the measurement circuit is composed of a photoelectric detection circuit 6 and a temperature measurement circuit 7; the control circuit is composed of a controller 9 and The refrigeration driving circuit 8 is composed; the measuring circuit is respectively connected with the photoelectric detection unit of the dew point chamber, the platinum resistor 4 and the controll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com