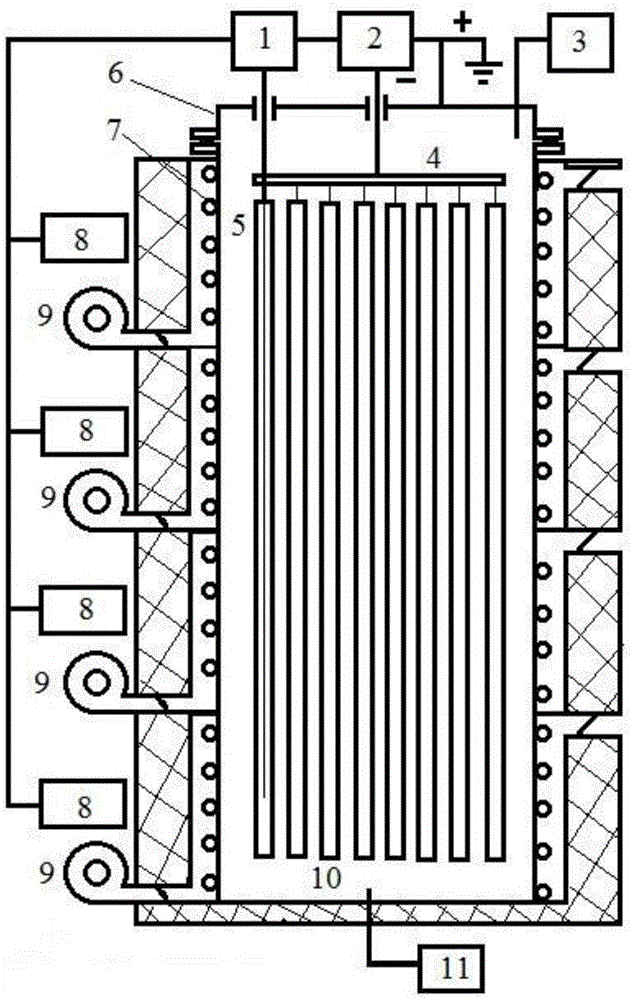

Low temperature ion hardening treatment device of austenitic stainless steel long and thin tube

A technology for austenitic stainless steel and stainless steel tubes, which is applied in metal material coating process, coating, solid diffusion coating and other directions to achieve the effect of reducing temperature difference, ensuring safety, and uniform axial temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0015] Embodiment: The effective working size of the low-temperature ion hardening treatment device for austenitic stainless steel elongated tubes of the present invention is φ1100mm × 5000mm (diameter × height), and the furnace is divided into 6 zones for heating, and 220 diameters φ10mm and 4m in length are suspended in the furnace. AISI 316L austenitic stainless steel pipe with a wall thickness of 0.5mm, and a stainless steel pipe inserted with 7 armored thermocouples, of which 6 armored thermocouples control the temperature of the six-zone furnace wall, and 1 is used to control the DC power supply output power. Hydrogen, nitrogen and methane are used as working gases for ion nitrocarburizing hardening of austenitic stainless steel pipes. Hang the cleaned stainless steel tube on the cathode plate, cover the furnace cover and pre-evacuate to 5Pa, turn on the external auxiliary heater, heat the stainless steel tube to 300°C, feed 1000mL / min hydrogen, turn on the DC power supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com