Air cooling 350MW turbine generator

A steam turbine generator, air cooling technology, applied in the direction of cooling/ventilation devices, electromechanical devices, electrical components, etc., can solve the problems of ineffective cooling, ineffective cooling of rotor windings, temperature rise of rotor windings, etc., to achieve unit operation Safe and reliable, the axial temperature is basically uniform, and the effect of solving local overheating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] specific implementation plan

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

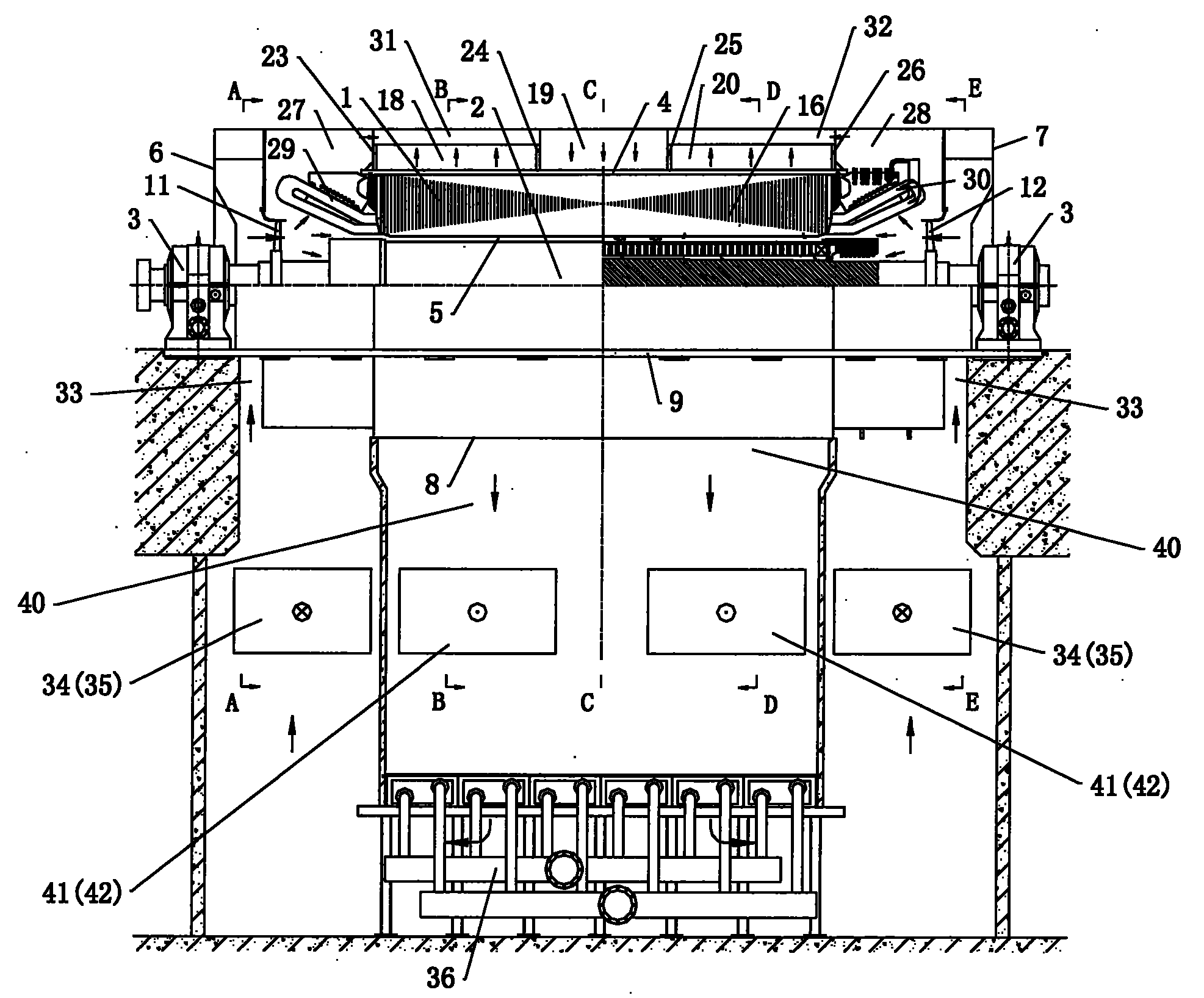

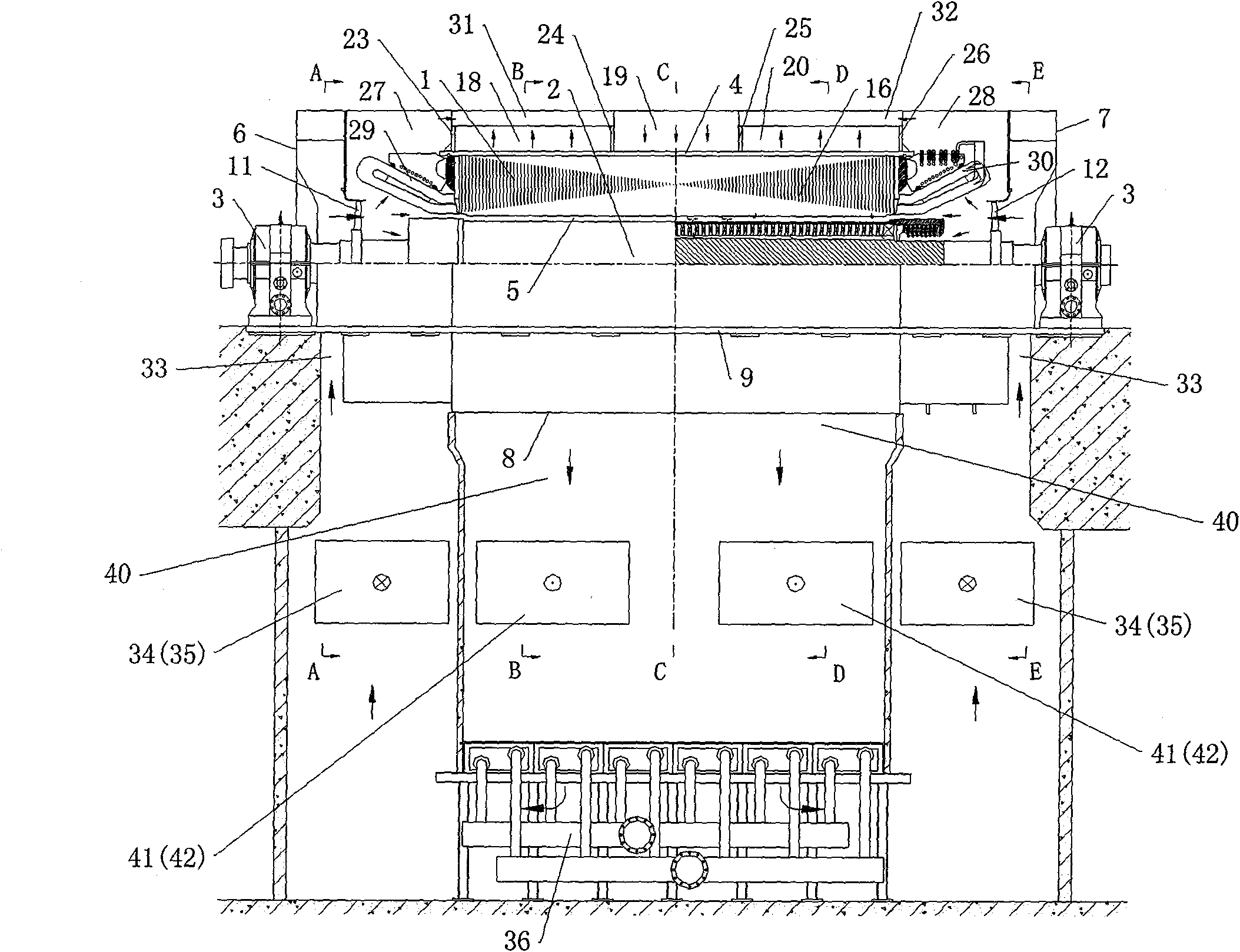

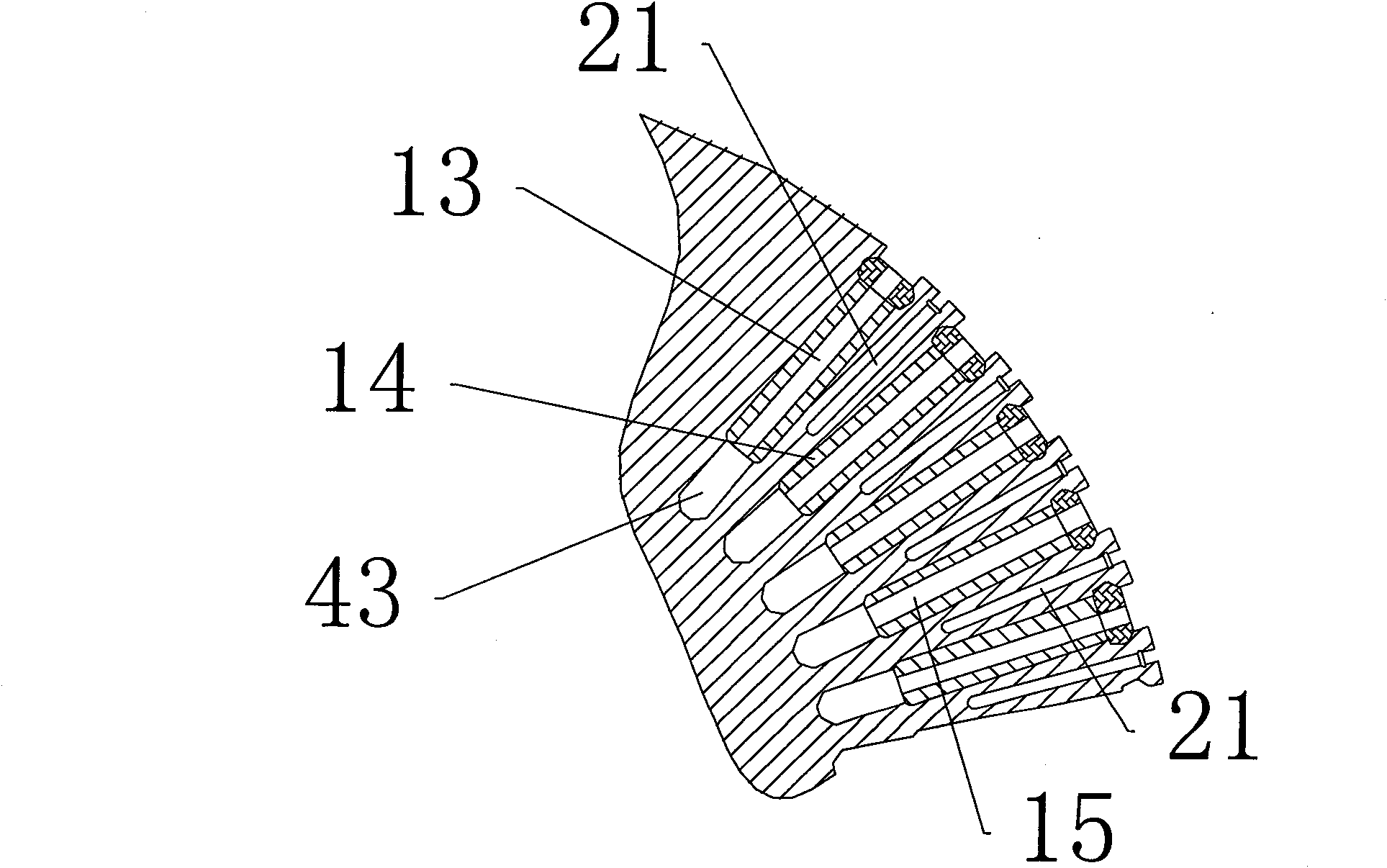

[0024] Referring to the air-cooled 350MW turbogenerator shown in Figure 1-7, both ends of the rotor 2 penetrating into the stator 1 are rotatably supported on the bearing 3, and the stator is set in the frame 4; there is a circumferential air gap between the stator and the rotor 5; front end cover 6, rear end cover 7 are arranged at the two ends of support, and air outlet bucket (bottom cover) 8 is arranged at the support bottom, and base plate 9 is arranged at support bottom both sides. The windshield 10 is arranged on the left and right sides of the base and connects with the bottom plate. Both ends of the rotor are provided with a front axial flow fan 11 and a rear axial flow fan 12. The rotor is provided with a wire slot 13 along the axial direction, and a wire slot 43 is opened along the axi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com