Ash residue treatment method and autoclaved brick manufacturing method

A technology for ash and slag treatment and autoclaved bricks, which is applied in the manufacture of combustible gas, bulk chemical production, gasification process, etc. The effect of shrinking and promoting digestion speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

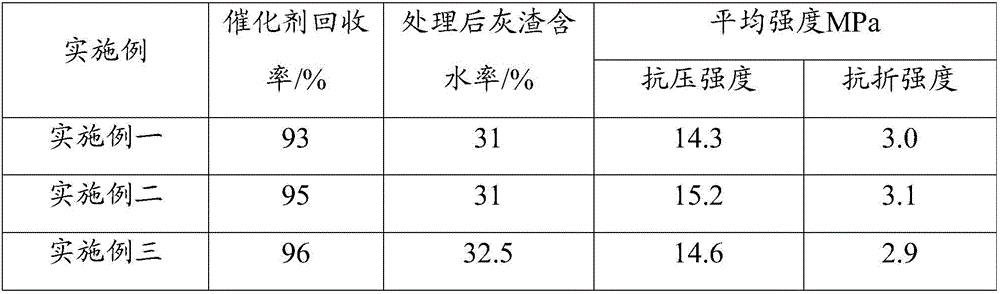

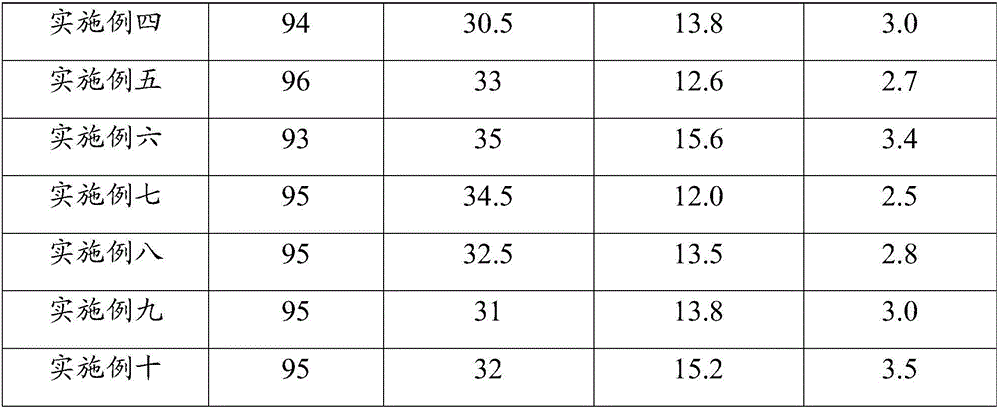

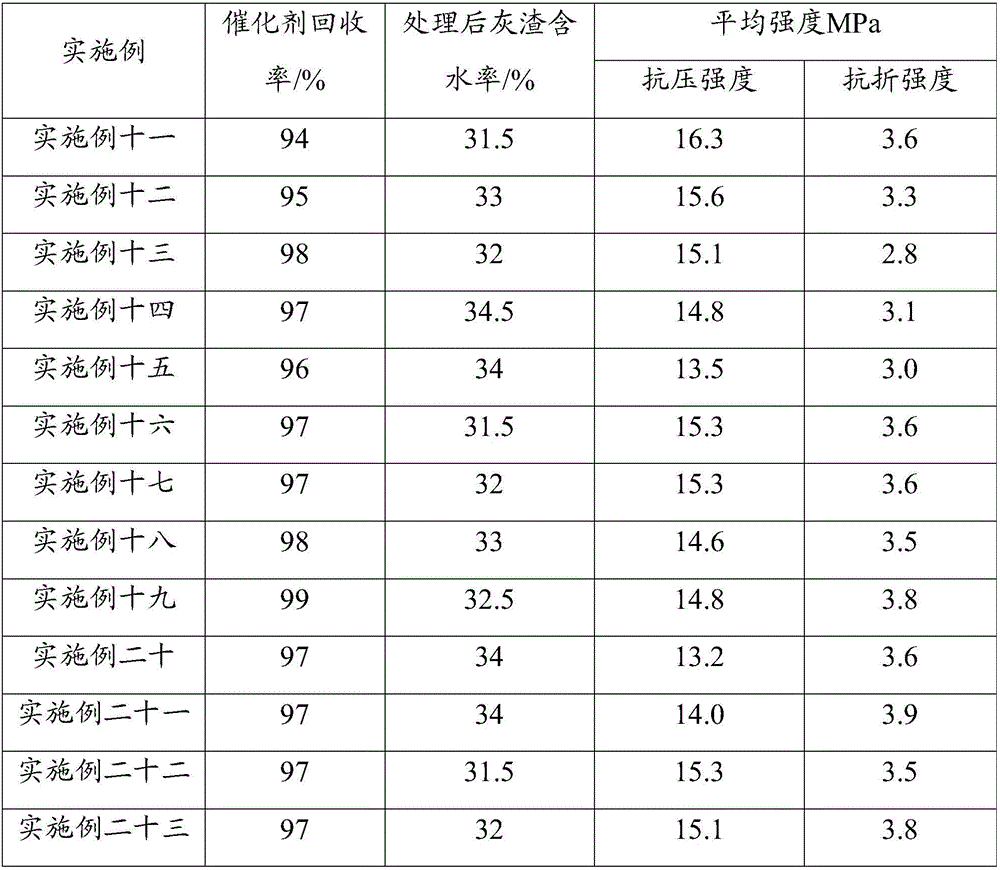

Examples

Embodiment 1

[0049] The ash processing method of the present embodiment adopts a one-step method to process ash, and the specific steps include the following processes:

[0050] According to the mass ratio of 60:40:120:1:75, gasification ash, calcium oxide, deionized water, natural gypsum, and stone chips are added to the reactor for reaction to obtain a one-step reaction mixed system. Calcium oxide will The water-insoluble catalyst in the gasification ash is digested into a water-soluble catalyst, and the water-soluble catalyst in the gasification ash is extracted with deionized water; the reaction temperature is 120°C, the reaction pressure is 0.2MPa, and the reaction time is 2h. in,

[0051] In the calcium oxide used, the mass percentage of calcium oxide with a particle diameter greater than 0.080mm is 20%, the mass percentage of calcium oxide with a particle diameter less than 0.080mm is 80%, and the mass percentage of calcium oxide with a particle diameter greater than 0.20mm is 10%; ...

Embodiment 2

[0057] The ash processing method of the present embodiment adopts a one-step method to process ash, and the specific steps include the following processes:

[0058] According to the mass ratio of 80:20:400:3:40, gasification ash, calcium hydroxide, tap water, desulfurized gypsum, and sand are added to the reactor for reaction to obtain a one-step reaction mixed system. The water-insoluble catalyst in the gasification ash is digested into a water-soluble catalyst, and tap water is used to extract the water-soluble catalyst in the gasification ash; the reaction temperature is 200°C, the reaction pressure is 1.6MPa, and the reaction time is 2h. in,

[0059] In the calcium hydroxide used, the mass percentage of calcium hydroxide with a particle diameter greater than 0.080mm is 18%, the mass percentage of calcium hydroxide with a particle diameter less than 0.080mm is 88%, and the mass percentage of calcium hydroxide with a particle diameter greater than 0.20mm Among the gasificat...

Embodiment 3

[0065] The ash processing method of the present embodiment adopts a one-step method to process ash, and the specific steps include the following processes:

[0066] According to the mass ratio of 120:10:10:960:7:40, gasification ash, calcium hydroxide, calcium oxide, water washing tower wastewater, phosphogypsum, and stone chips are added to the reactor for reaction to obtain a one-step reaction Mixed system, calcium hydroxide digests the non-water-soluble catalyst in the gasification ash into a water-soluble catalyst, and the water-soluble catalyst in the gasification ash is extracted from the wastewater of the water washing tower; the reaction temperature is 280°C, and the reaction pressure is 6.5MPa , The reaction time is 2h. in,

[0067] In the calcium hydroxide used, the mass percentage of calcium hydroxide with a particle diameter greater than 0.080mm is 20%, the mass percentage of calcium hydroxide with a particle diameter less than 0.080mm is 80%, and the mass percentag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com