Road dust suppressant, and preparation and construction method thereof

A dust suppressant and road technology, applied in chemical instruments and methods, cleaning methods, road surface cleaning, etc., can solve the problems of cumbersome steps, short moisturizing and moisture absorption time, increased slipperiness, etc., and achieve strong moisture absorption and moisture retention, excellent dust suppression effect, the effect of reducing carbon black

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

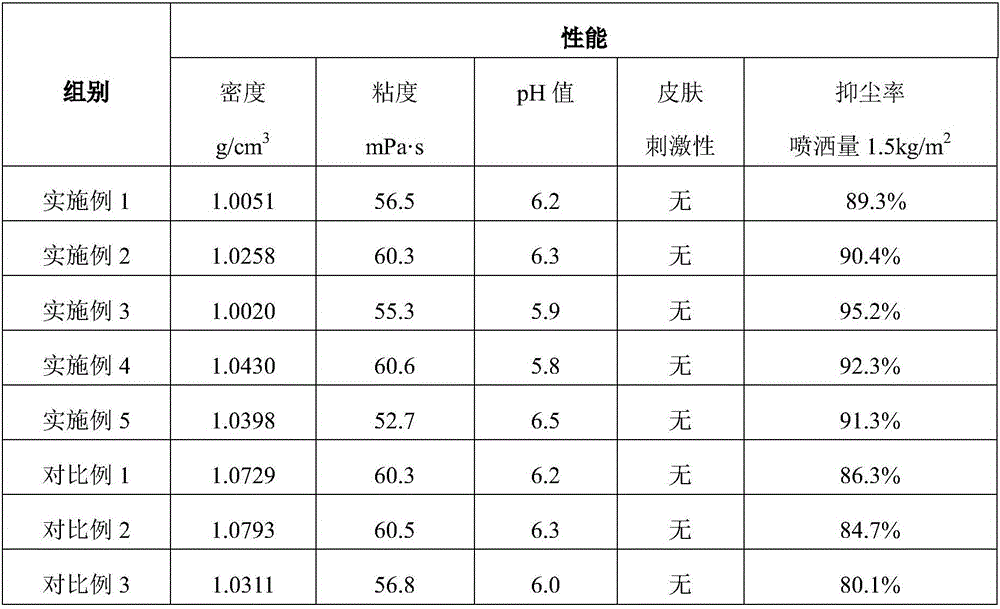

Examples

Embodiment 1

[0027] The road dust suppressant is composed of the following components by weight percentage: 0.1% styrene and butadiene copolymer rubber powder, 10% EVA emulsion, 5.0% polyacrylamide, 0.01% chitosan, 5% calcium chloride, 0.1% containing Fluorosurfactant, 10% calcium carbonate, balance is water.

[0028] Preparation methods include:

[0029] Step 1: Fully mix 5.0% polyacrylamide with water and stir for 5 minutes to completely dissolve the polyacrylamide to prepare an aqueous solution of polyacrylamide;

[0030] Step 2: Add 0.01% chitosan, 5% calcium chloride, 0.1% fluorosurfactant, 10% calcium carbonate to the aqueous solution prepared in step 1, stir and mix evenly;

[0031] Step 3: Add 0.1% styrene-butadiene copolymer rubber powder and 10% EVA emulsion to the mixed solution obtained in step 2, and stir evenly to obtain the road dust suppressant.

Embodiment 2

[0033] The road dust suppressant is composed of the following components by weight percentage: 2% acrylate and styrene copolymer rubber powder, 0.5% fluorocarbon emulsion, 1.0% sodium polyacrylate superabsorbent resin, 0.1% chitosan, 0.1% chitin, 8% propylene glycol, 0.1% sodium dodecylsulfonate, 20% diatomaceous earth, and the balance is water.

[0034] Preparation methods include:

[0035] Step 1: Fully mix 1.0% sodium polyacrylate superabsorbent resin with water, and stir for 10 minutes, so that the polyacrylic acid superabsorbent resin is fully swollen to prepare a water absorbent resin solution;

[0036] Step 2: Add 0.1% chitosan, 0.1% chitin, 8% propylene glycol, 0.1% sodium dodecylsulfonate, 20% diatomaceous earth to the aqueous solution prepared in step 1 and stir to mix evenly;

[0037] Step 3: Add 2% acrylate and styrene copolymer rubber powder and 0.5% fluorocarbon emulsion to the mixed liquid obtained in Step 2 and stir evenly to obtain the road dust suppressant. ...

Embodiment 3

[0039] The road dust suppressant is composed of the following components by weight percentage: 0.5% styrene and butadiene copolymerized rubber powder, 0.5% acrylate and styrene copolymerized rubber powder, 2% fluorocarbon emulsion, 3% styrene-acrylic emulsion, 1.0% Polyethylene glycol 4000, 1.0% polyethylene glycol 200, 0.1% chitosan, 5% glycerol, 0.1% polyoxyethylene alkylphenol ether, 0.05% polyoxyethylene fatty alcohol ether, 5% calcium carbonate, The balance is water.

[0040] Preparation methods include:

[0041]Step 1: Fully mix 1.0% polyethylene glycol 4000 and 1.0% polyethylene glycol 200 with water, stir for 8 minutes to dissolve completely, and make a mixed aqueous solution;

[0042] Step 2: Add 0.1% chitosan, 5% glycerol, 0.1% polyoxyethylene alkylphenol ether, 0.05% polyoxyethylene fatty alcohol ether, 5% calcium carbonate to the aqueous solution prepared in step 1 and stir to mix evenly ;

[0043] Step 3: Add 0.5% styrene-butadiene copolymerized rubber powder, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com