Preparation method of hemicellulose-based polyether polyol

A technology of polyether polyol and hemicellulose, applied in the field of organic chemical industry, can solve the problems such as no reports on the preparation of rigid foam polyether polyol from hemicellulose, so as to ensure low shrinkage, save production cost, and ensure no chalking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

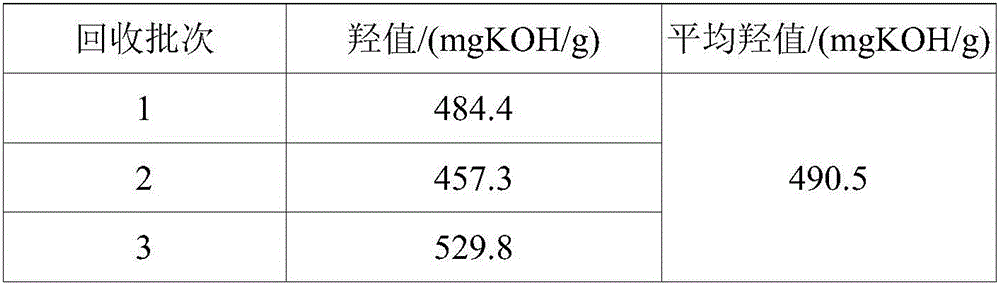

Embodiment 1

[0035] Accurately weigh 60g of hemicellulose, 8.5g of potassium hydroxide, and 350g of toluene, and add them into a high-pressure reaction kettle equipped with a stirrer, a thermometer, and a circulating condenser. After nitrogen replacement, raise the temperature to 95°C, and slowly Start to feed 214g of propylene oxide, finish adding 6h, control the reaction temperature between 110-120°C, the reaction pressure is less than 0.6MPa, keep warm until the pressure no longer drops, cool down to below 60°C, and discharge; phosphoric acid is neutralized to The pH is neutral, dehydrated under reduced pressure, and filtered to obtain hemicellulose polyether polyol with a viscosity of 968mPa.s and a hydroxyl value of 368mgKOH / g, which can be used as a raw material for polyurethane rigid foam.

Embodiment 2

[0037]Accurately weigh 30g of hemicellulose, 15g of glycerin, 4g of potassium hydroxide, and 350g of toluene, and add them to a high-pressure reactor equipped with a stirrer, a thermometer, and a circulating condenser. After nitrogen replacement, raise the temperature to 95°C and stir at a constant speed. Slowly start to add 96g of propylene oxide dropwise, after 3 hours, control the reaction temperature at 130-140°C, and the reaction pressure is less than 0.6MPa, keep the temperature until the pressure no longer drops, cool down to below 60°C, and discharge; phosphoric acid is neutralized to The pH is neutral, and the hemicellulose polyether polyol is obtained by dehydration under reduced pressure and filtration. The appearance is a brownish yellow liquid, the viscosity is 3280mPa.s, and the hydroxyl value is 395mgKOH / g, which can be used as a raw material for polyurethane rigid foam.

Embodiment 3

[0039] Accurately weigh 40g of hemicellulose, 25g of glycerin, 6g of potassium hydroxide, and 350g of toluene, and add them to a high-pressure reactor equipped with a stirrer, a thermometer, and a circulating condenser. After nitrogen replacement, raise the temperature to 95°C and stir at a constant speed. Slowly start to feed 175g of propylene oxide, and finish adding in 4 hours, control the reaction temperature at 120-130°C, the reaction pressure is less than 0.6MPa, keep warm until the pressure no longer drops, cool down to below 60°C, and discharge; phosphoric acid is neutralized to pH It is neutral, dehydrated under reduced pressure and filtered to obtain hemicellulose polyether polyol, which is a brownish-yellow liquid with a viscosity of 2750mPa.s and a hydroxyl value of 390mgKOH / g, which can be used as a raw material for polyurethane rigid foam.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com