Bioceramic operation scissors and application thereof

A technology of bioceramics and bioceramic materials, applied in the field of bioceramic surgical scissors and application fields, can solve the problems of high brittleness of bioceramic materials, prone to cracks, limited processing performance, etc., so as to improve fracture toughness and fracture strength, increase Lubricity, the effect of inhibiting crystal transformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

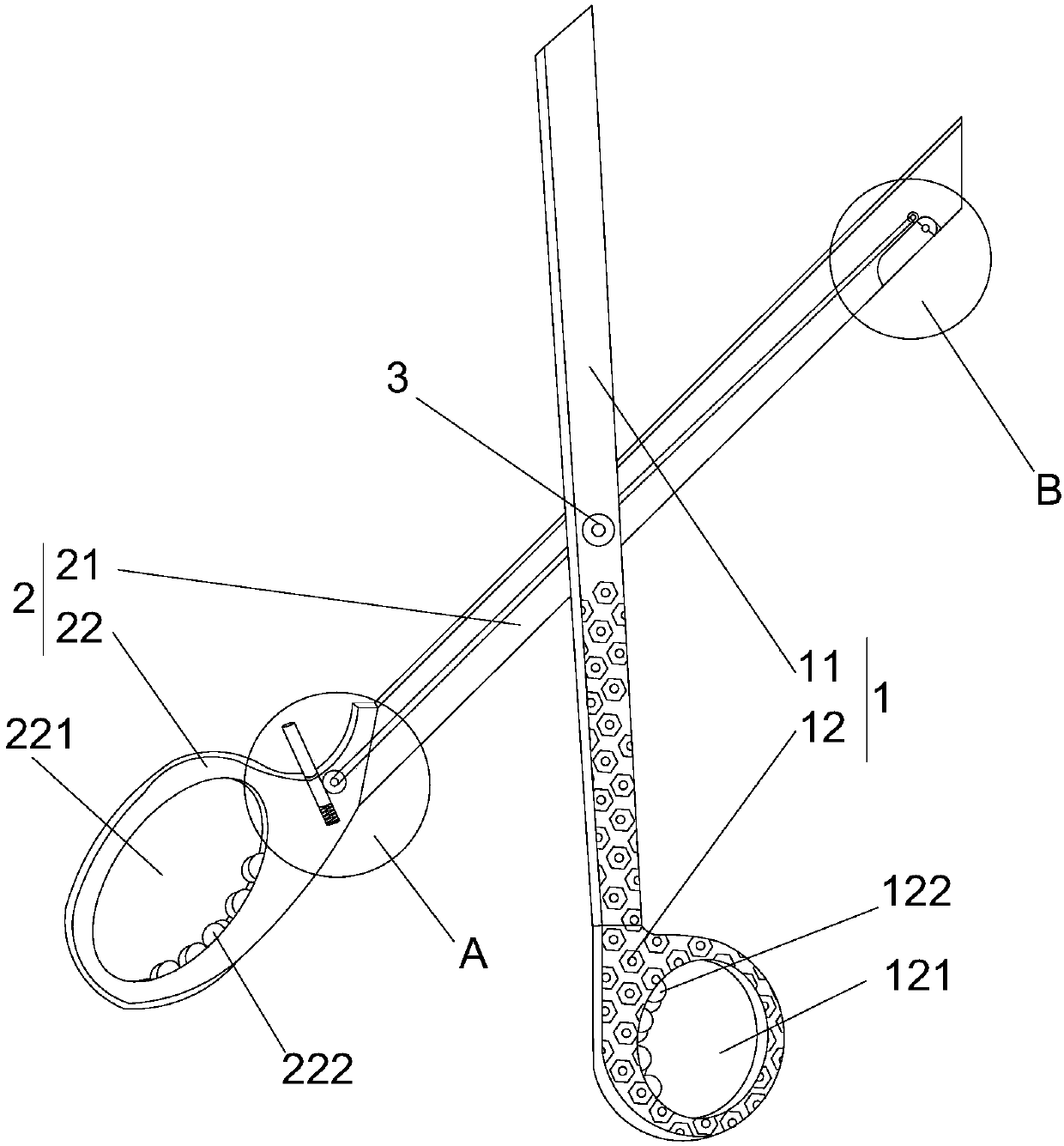

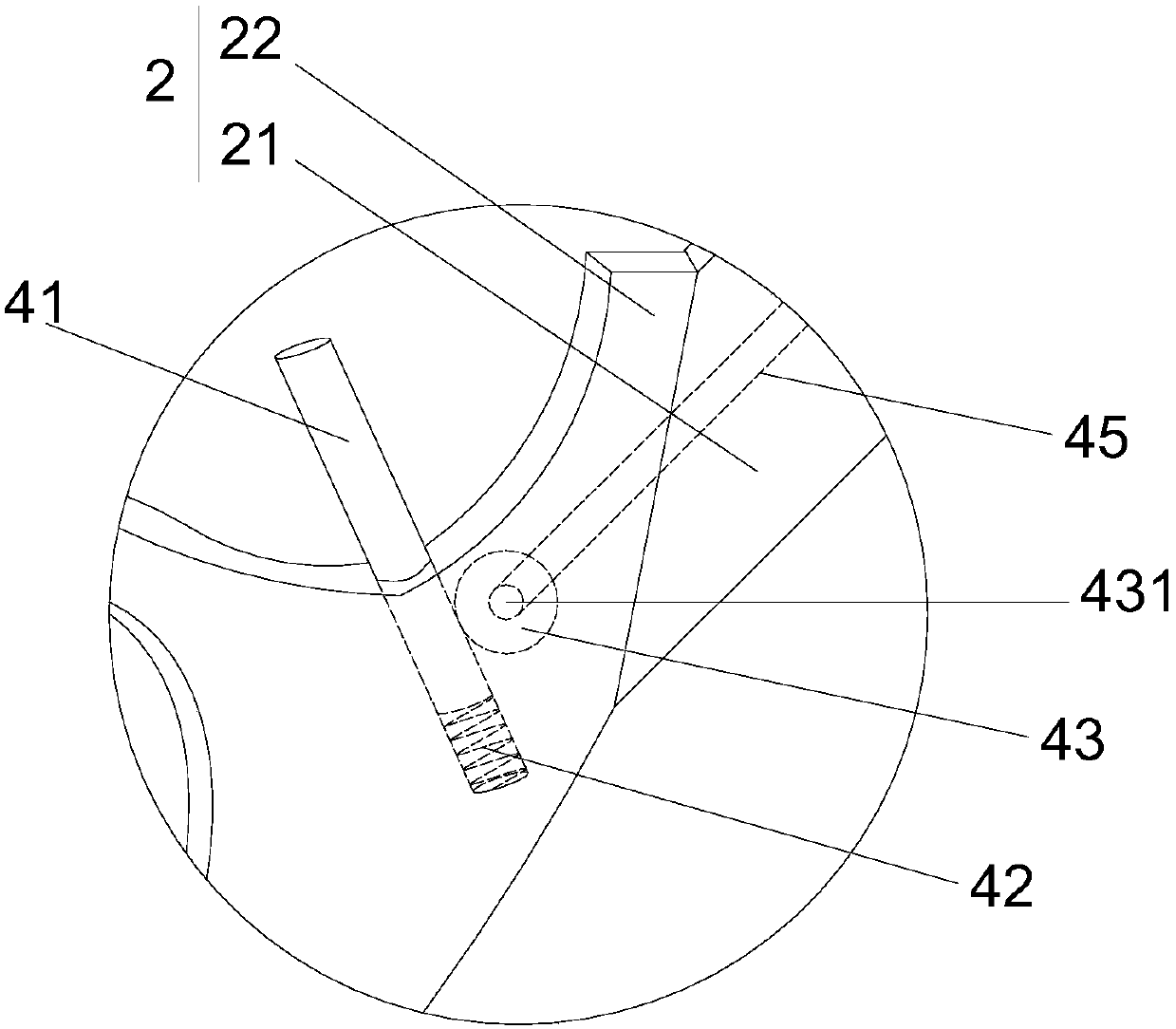

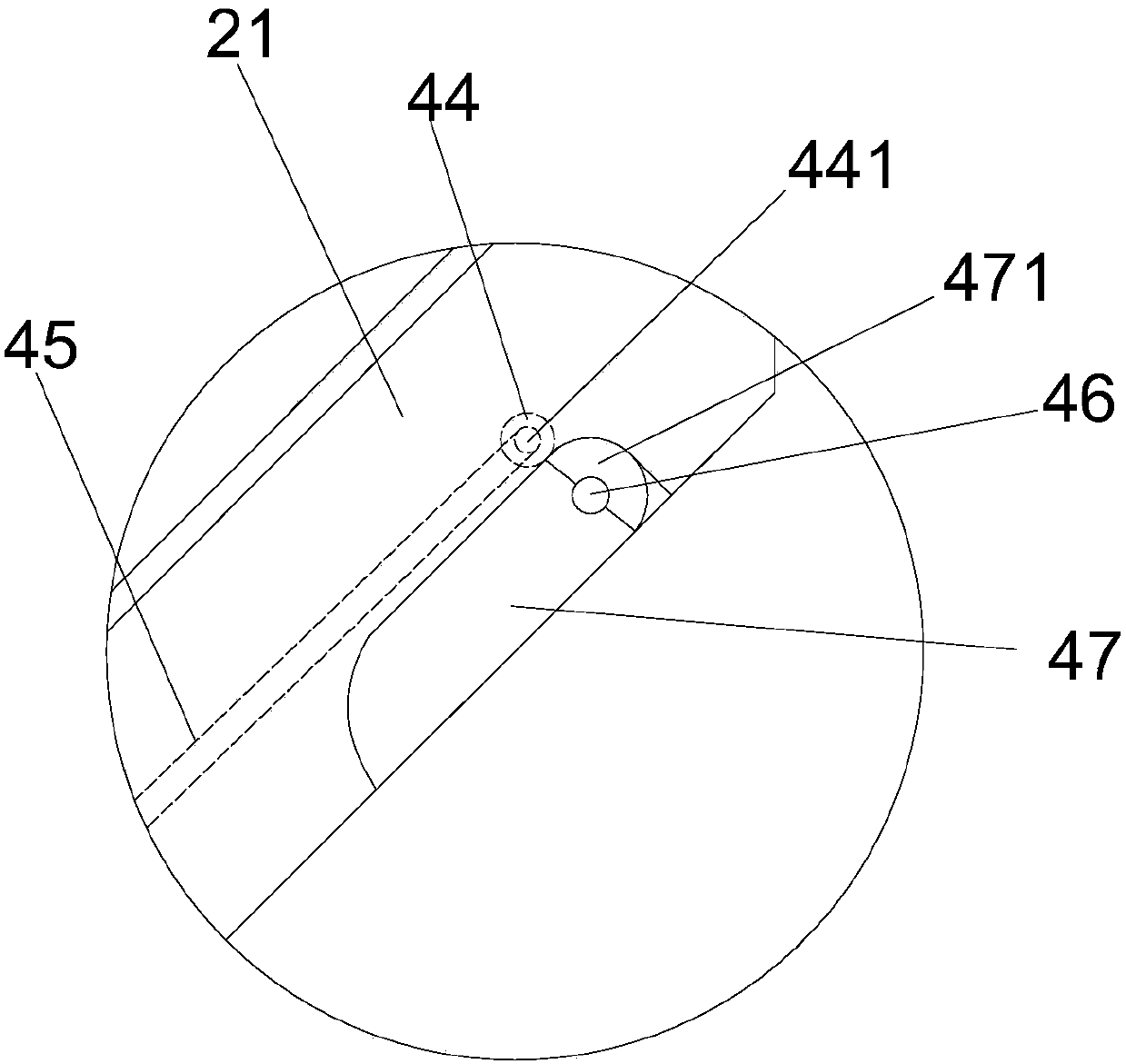

[0049] refer to figure 1 , figure 2 and image 3 As shown, a bioceramic surgical scissors proposed by the present invention includes a first cutting part 1, a second cutting part 2 and a first rotating shaft 3;

[0050] The first cutting part 1 comprises a first scissors arm 11 and a first finger ring 12, the second cutting part 2 comprises a second scissors arm 21 and a second finger ring 22, and both the first scissors arm 11 and the second scissors arm 21 can rotate Installed on the first rotating shaft 3, the first finger ring 12 and the second finger ring 22 are respectively installed on the first scissors arm 11 and the second scissors arm 21, and the first finger ring 12 and the second finger ring 22 are respectively provided with first finger-fastening holes 121 and the second finger hole 221; the first shearing part 1 is provided with a hexagonal pattern on the side of the first rotating shaft 3 close to the first finger ring 12; the first shearing part (1) and the s...

Embodiment 2

[0053] Based on Example 1, the bioceramic material is prepared by the following process:

[0054] S1. Weigh raw materials by weight: 80 parts of zirconia, 20 parts of titanium nitride, 10 parts of graphite, 1 part of four-needle zinc oxide whisker, 1 part of yttrium oxide, 1 part of cerium oxide, and 1 part of aluminum oxide;

[0055] S2. Divide the zirconia into 3 parts, place them in ball milling media for ball milling respectively, and obtain 3 kinds of A powder, B powder and C powder with different particle sizes;

[0056] S3. Mix the remaining raw materials evenly, divide them into 3 parts, add them to A powder, B powder and C powder and mix evenly to obtain 3 kinds of mixed materials;

[0057] S4, the 3 kinds of mixed materials obtained in S3 are superimposed and laminated, and pre-pressed to obtain a rough billet;

[0058] S5. Introduce protective gas into the sintering system, place the rough body obtained in S4 in the sintering system, raise the temperature to 1300°C...

Embodiment 3

[0060] Based on Example 1, the bioceramic material is prepared by the following process:

[0061] S1. Weigh raw materials by weight: 100 parts of zirconia, 30 parts of titanium nitride, 20 parts of graphite, 5 parts of four-needle zinc oxide whiskers, 5 parts of yttrium oxide, and 3 parts of cerium oxide;

[0062] S2. Divide the zirconia into 3 parts and place them in the ball milling medium for 15h, 10h and 5h, respectively, to obtain 3 different particle sizes A powder, B powder and C powder; the particle sizes of A powder, B powder and C powder are respectively 320nm , 370nm, 420nm;

[0063] S3. Mix the remaining raw materials evenly, divide them into 3 parts, add them to A powder, B powder and C powder and mix evenly to obtain 3 kinds of mixed materials;

[0064] S4. Dividing the mixed material containing C powder into two parts as the bottom layer and the top layer, laying the two mixed materials containing A powder and B powder between the top layer and the top layer re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com