Pavement net-shaped crack and fracturing crack welding material and construction method thereof

A construction method and technology for pavement cracks, applied in the direction of roads, roads, road repair, etc., can solve the problems of inability to fill small cracks, cracks are prone to repeated cracking, etc., and achieve the effects of enhanced toughness, stable joint structure, and wide construction conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

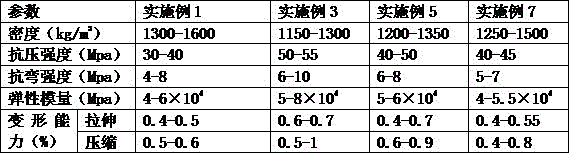

Examples

Embodiment 1

[0028] The present embodiment provides a kind of welding material for pavement network cracks and cracks, including 70 parts of sand and gravel materials, 8 parts of polymer materials, 10 parts of dispersible latex powder, 3 parts of additives and 1 part of foaming agent by weight. Wherein, the polymer material is methyl methacrylate; the dispersible latex powder is a copolymer of ethylene / vinyl acetate; the additive is butyl acrylate, xylylenediamine and ethylenediamine; the blowing agent is calcium carbonate and magnesium carbonate.

[0029] Preferably, it includes 70-80 parts by weight of sand and gravel material, 8-12 parts of polymer material, 10-15 parts of dispersible latex powder, 3-6 parts of additive and 1-3 parts of foaming agent.

Embodiment 2

[0031] This embodiment provides a construction method for the welding material of cracks and cracks on the pavement described in Example 1, including pretreatment, preparation, welding and detection of the welding material, wherein

[0032] Pretreatment: Clean up the dust and debris on the surface of the cracks on the road surface, and select the material diameter of the sand and gravel materials within the range of 0-0.5 mm according to the width and depth of the cracks;

[0033] Preparation of solder: uniformly mix sand and gravel materials, polymer materials, dispersible latex powder and additives to obtain mixture A, add foaming agent to mixture A and mix uniformly to obtain mixture B;

[0034] Welding: Fill the mixture B evenly at the bottom of the road surface cracks, and fill the mixture A above the mixture B. The thickness of the mixture A is 5 mm, and the upper surface of the mixture A is flush with the road surface; during the filling process, the distance between the...

Embodiment 3

[0037] The present embodiment provides a kind of welding material for pavement network cracks and cracks, comprising 85 parts by weight of gravel materials, 15 parts of polymer materials, 15 parts of dispersible latex powder, 8 parts of additives and 5 parts of foaming agent, Wherein, the polymer material is polyurethane, liquid resin and methyl methacrylate; the dispersible latex powder is vinyl acetate / ethylene tertiary carbonate copolymer and acrylic acid copolymer; the additive is polyacrylic acid; and the foaming agent is sodium bicarbonate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com