Grinding machine table

A technology of grinding machine and machine table, which is applied in the direction of grinding frame, grinding bed, grinding slide plate, etc. It can solve the problems affecting the high-precision processing of the grinding machine, the crawling of the screw rod, and the single processing method, so as to ensure the processing accuracy , easy to operate, and ensure the effect of processing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

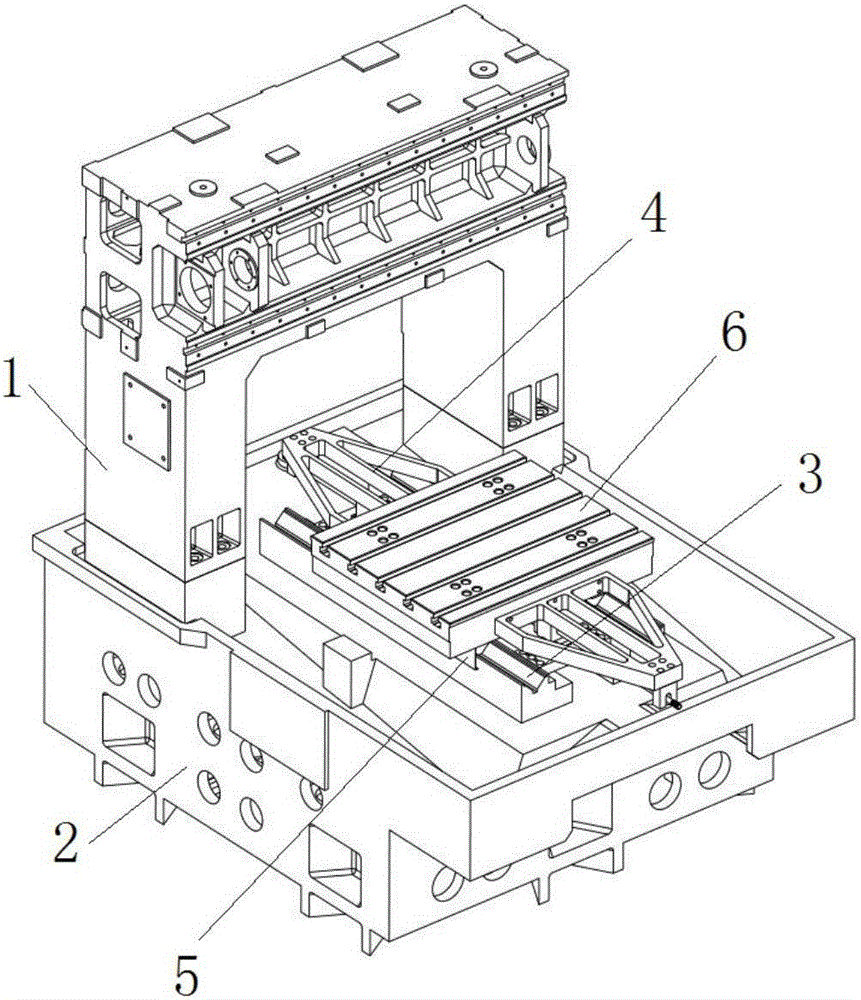

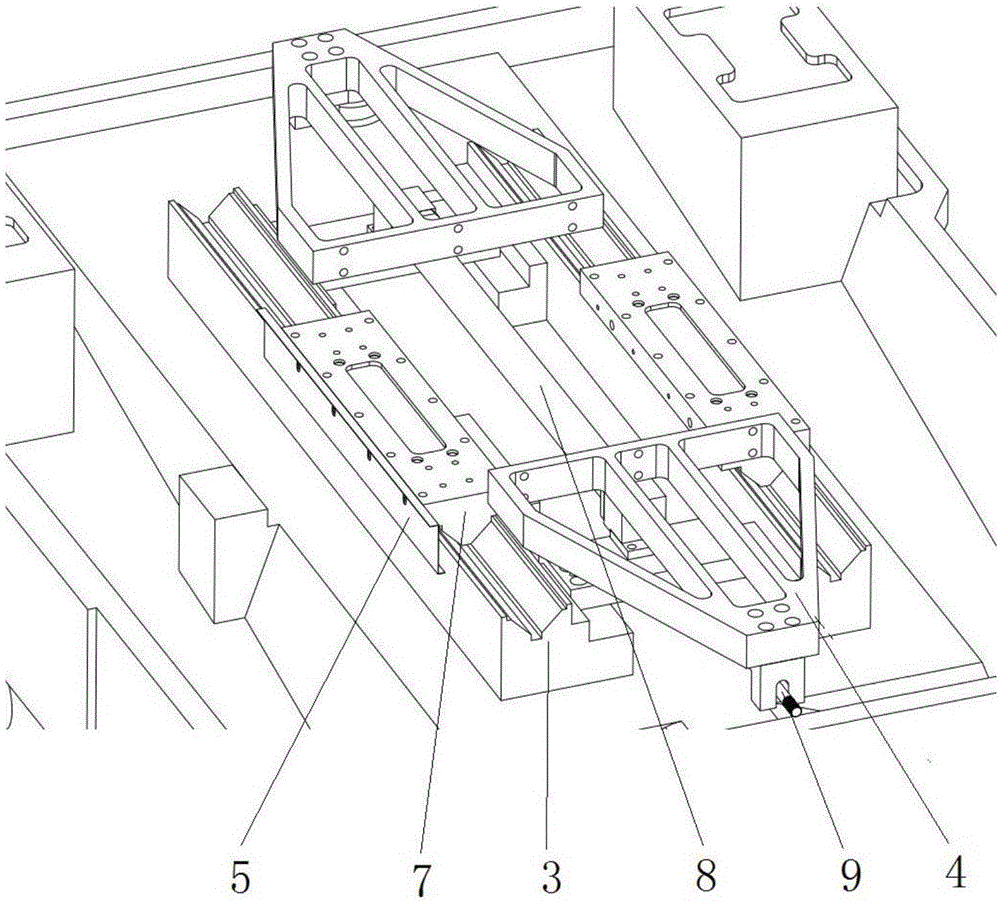

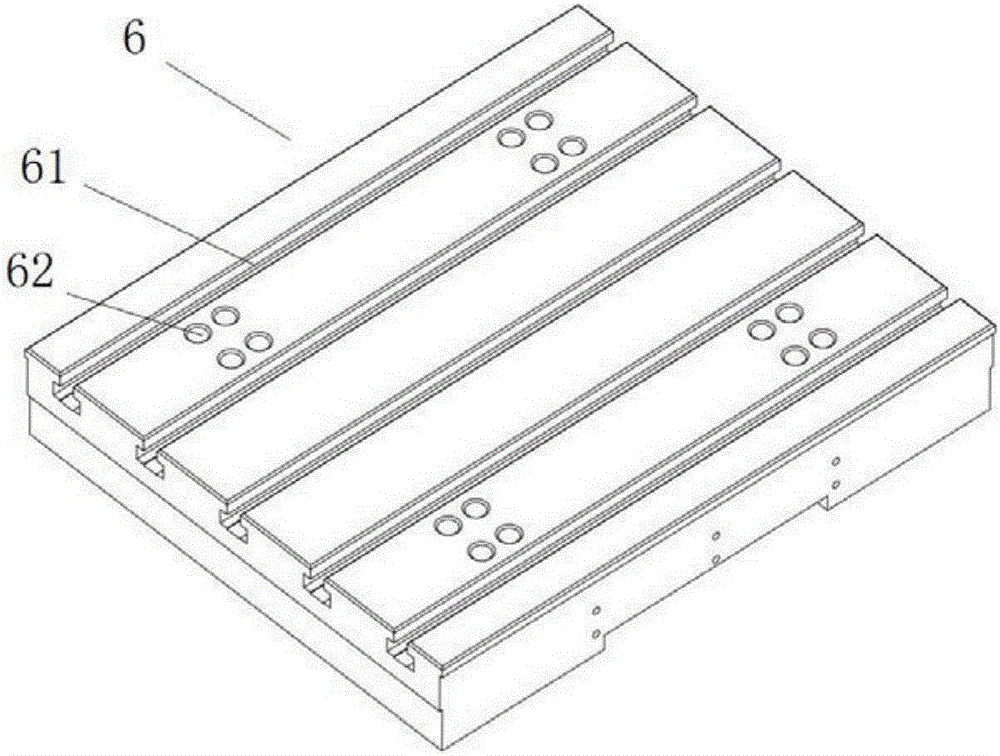

[0012] Such as Figure 1 to Figure 4 As shown, the present embodiment provides a grinding machine platform, which includes a double-column grinding head mechanism 1 and a Y-axis grinding machine platform 2; the Y-axis grinding machine platform 2 is provided with two parallel V-shaped guide rail 3; hydraulic rod supports 4 are respectively provided at the front and rear positions of the Y-axis direction of the Y-axis grinder machine table 2; a workbench 6 is connected between the two hydraulic rod supports 4; the left and right sides of the bottom of the workbench 6 Each is fixed with a V-shaped slide block 7 to cooperate with the V-shaped guide rail 3; a hydraulic cylinder 8 is provided directly below the workbench 6 along the Y-axis direction, and the two ends of the hydraulic rod are connected to the ends of the two hydraulic rod supports 4 respectively. connection; the outside of the V-shaped slider 7 is fixed with a dust cover 5; the workbench 6 is provided with a pluralit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com