A kind of start-up method of hydrogenation catalyst

A hydrogenation catalyst and hydrogenation activity technology, which is applied in the fields of start-up, chemical instruments and methods, catalyst regeneration/reactivation, etc. of hydroprocessing operations, and can solve metal waste, shorten start-up time, and poor dispersion of active metals, etc. problems, to achieve the effect of increasing the initial vulcanization temperature, shortening the start-up time, and good metal dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The preparation of embodiment 1 catalyst carrier

[0042] (1) Preparation of carrier A-1

[0043] Weigh 900g of macroporous pseudoboehmite (73wt% on a dry basis), 19g of scallop powder, 32g of citric acid, 48mL of nitric acid (30wt%), 159mL of silica gel (containing 30wt% of silicon dioxide), polystyrene and Mix 20g each of polyethylene glycol 2000 and 250mL deionized water evenly, extrude into 1.2mm clover strips on an extruder, dry at 120°C for 4 hours, and roast at 600°C for 3 hours to obtain carrier A-1, and the pore volume of carrier A-1 0.7cm 3 / g, the average pore diameter is 35.6nm, and the strength is 176N / cm.

[0044] (2) Preparation of carrier A-2

[0045] Weigh 830g of macroporous pseudo-boehmite (73wt% on a dry basis), 19g of scallop powder, 32g of citric acid, 48mL of nitric acid (30wt%), 200mL of silica gel (containing 30wt% of silicon dioxide), and 50g of alumina powder , 20g each of polystyrene and polyethylene glycol 2000, and 250mL of deionized wa...

Embodiment 2

[0047] (1) Preparation of hydrogenation catalyst B

[0048] Weigh 20.6 g of ammonium molybdate, 14.1 g of nickel nitrate, and 30 mL of ammonia water, and mix them with deionized water to 100 mL to obtain impregnating solution I. Measure the impregnation solution I according to the water absorption rate of 100mL / 100g and spray the impregnation carrier A-1. After spraying, heat treatment at low temperature at 80°C for 3 hours. Take 20g of 2,4,6-trimercapto-s-triazine triammonium salt and dissolve it in 50mL of water to obtain impregnation solution II. Spray the sample with impregnation solution II for low-temperature heat treatment, and dry it in the shade in a ventilated place to obtain hydrogenation catalyst B. Main physical properties See Table 1.

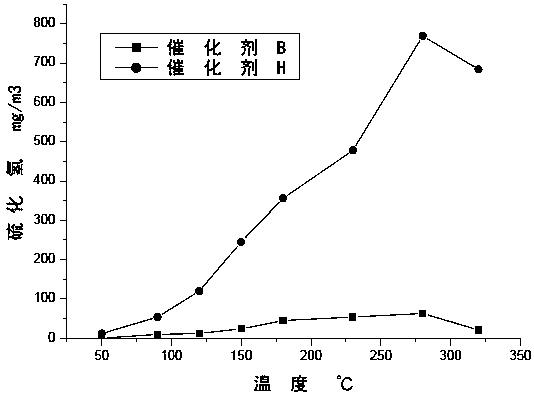

[0049] (2) Catalyst start-up method and evaluation

[0050] After introducing nitrogen into the catalyst reactor, adjust the system pressure to 2.0MPa, directly raise the temperature to 260°C at 25°C / h, keep the temperature for...

Embodiment 3

[0052] (1) Preparation of hydrogenation catalyst C

[0053] Weigh 20.6g of ammonium molybdate, 14.1g of nickel nitrate, and 30mL of ammonia water, mix them with deionized water to 100mL, and divide into 60mL and 40mL. Mix 60mL of the solution with deionized water evenly to 100mL to obtain the soaking solution I. Then measure the impregnation solution I according to the water absorption rate of 100mL / 100g and spray the impregnation carrier A-1, and then perform the first low-temperature heat treatment, the first low-temperature heat treatment condition is: 100°C low-temperature heat treatment for 3 hours. Dissolve 50 g of 2,4,6-trimercapto-s-triazine monoammonium salt in 50 mL of water to obtain impregnation solution II, spray the sample with impregnation solution II for the first low-temperature heat treatment, and then conduct the second low-temperature heat treatment, and the second low-temperature heat treatment The conditions are: 120 ℃ low temperature heat treatment for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com