Power control device for high-frequency dielectric heating and its control method

A technology of medium heating and power control unit, which is applied in the direction of electric heating device, electric/magnetic/electromagnetic heating, microwave heating, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

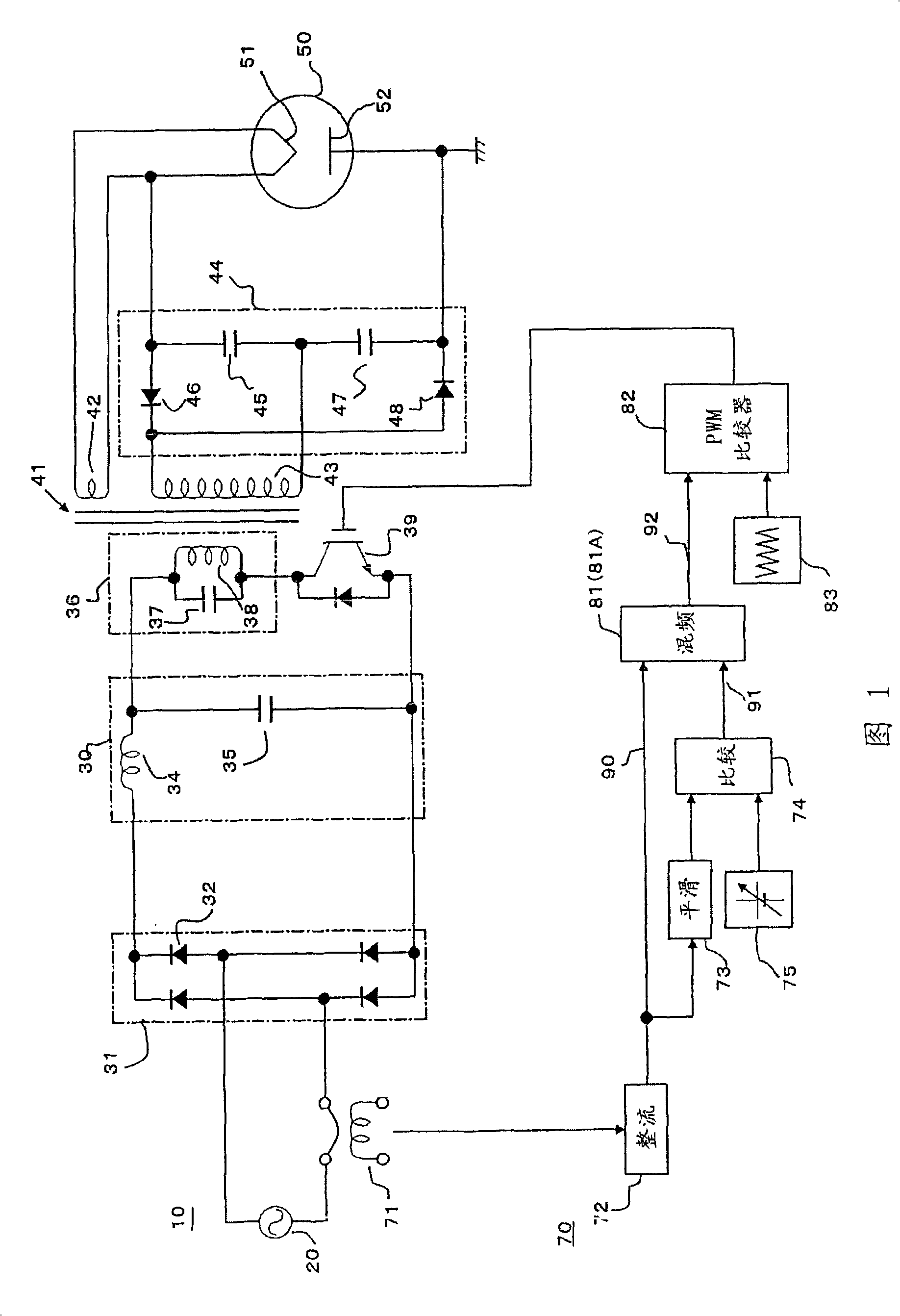

[0143] FIG. 1 is a block diagram illustrating a high-frequency dielectric heating power control unit according to a first embodiment of the present invention. In FIG. 1 , the high-frequency heating unit is composed of an inverter circuit 10 , a control circuit 70 for controlling a switching transistor 39 of the inverter, and a magnetron 50 . The inverter circuit 10 includes an AC power source 20 , a diode bridge rectification circuit 31 , a smoothing circuit 30 , a resonance circuit 36 , a switching transistor 39 and a voltage amplification rectifier 44 .

[0144] The AC voltage of the AC power source 20 is rectified by a diode bridge rectification circuit 31 composed of four diodes 32 and converted into a DC voltage by a smoothing circuit 30 composed of an inductor 34 and a capacitor 35 . Then, through the resonant circuit 36 and the switching transistor 39 composed of the capacitor 37 and the primary coil 38 of the transformer 41, the DC voltage is converted into high-fr...

no. 2 example

[0172] Next, a second embodiment of the present invention will be described. A second embodiment of the present invention relates to the configuration of a control circuit. Compared with the related art example in FIG. 32, except that the inverting circuit is incorporated in the mixing circuit 81A as shown in FIG. 1, the diode 261, shaping circuit 262, variable gain amplifier circuit 291, inverting and the waveform processing circuit 263 and the waveform error detection circuit 292, so that a significant reduction is achieved, the waveform error detection line is significantly simplified, the miniaturization of the machine configuration is facilitated, the control process is simplified, and the processing time can be shortened, thereby improving the machine reliability.

[0173] The input current waveform information 90 and the power control information 91 from the comparison circuit 74 are mixed, and the mixed information is filtered and converted into an on / off drive signal...

no. 3 example

[0175] The third embodiment relates to an input current detection section. As shown in FIG. 1 , the above-described input current detection section detects an input current to the inverter circuit through a CT 71 and the like, and rectifies and outputs it through a rectification circuit 72 . In this configuration, since the input current is detected using CT or the like, a large signal can be taken out while maintaining the insulation properties, making the effect of input current waveform shaping large, and improving the quality of the input current.

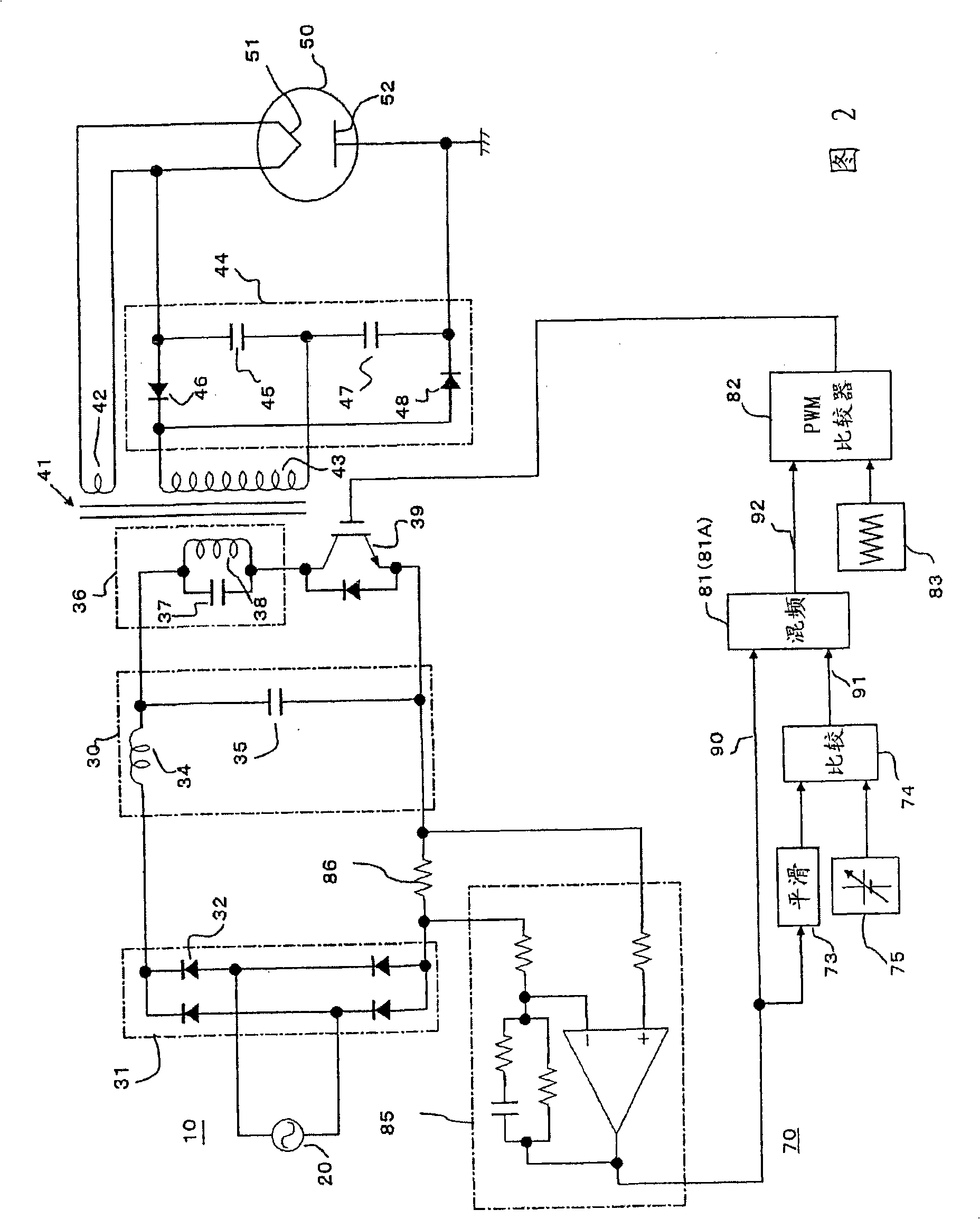

[0176] In the example shown in FIG. 2, the input current detection section detects the unidirectional current passing through the shunt resistor 86 located between the shaping circuit 31 and the smoothing circuit 30 after being shaped by the shaping circuit 31 of the inverter circuit, and passing through An amplification circuit (amplifier) 85 amplifies the voltage generated across the shunt resistor, and outputs the voltage....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com