Wire mesh loaded nano composite catalyst, preparation method thereof, and application of wire mesh loaded nano composite catalyst in alcoholic preparation of aldehyde ketone

A wire mesh and nano-composite technology, applied in the field of catalysis, can solve the problems of many by-products, poor low-temperature activity, and increased resistance of the reaction bed, and achieve the effects of low production cost, high low-temperature activity, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

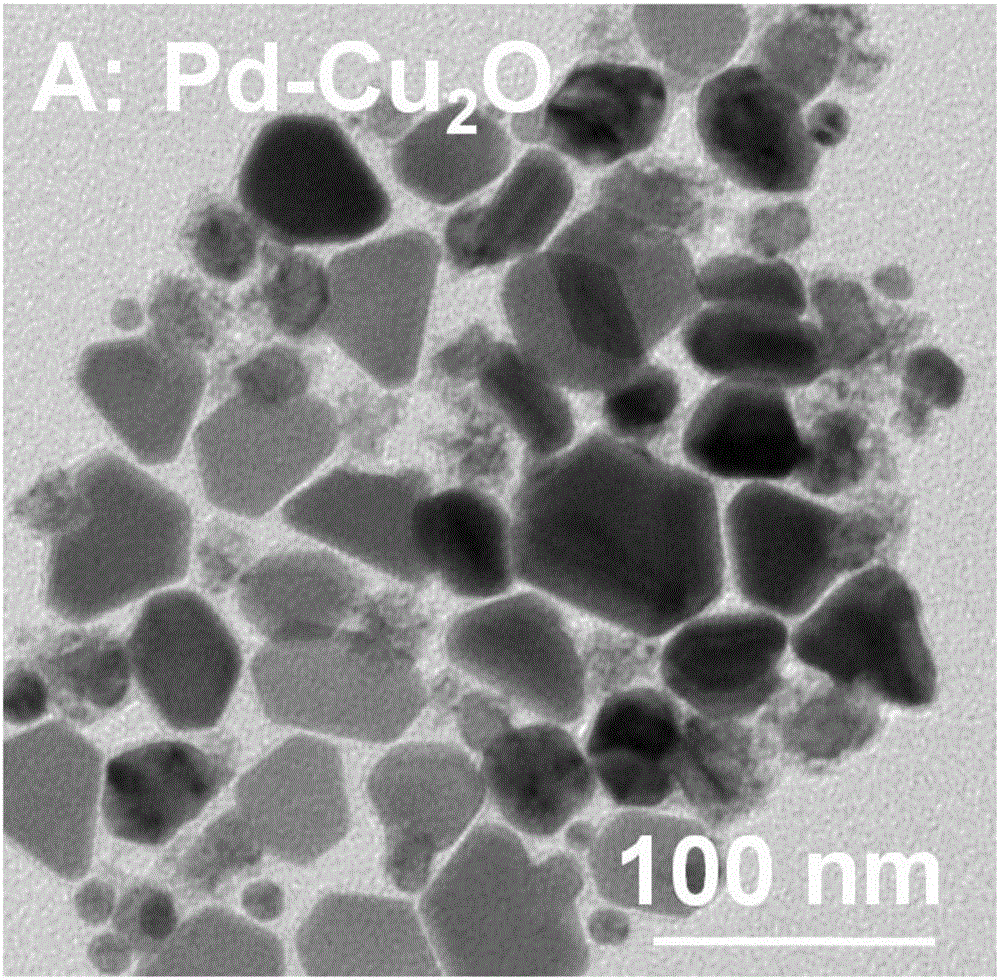

Image

Examples

preparation example Construction

[0025] The present invention provides a method for preparing a metal wire mesh-supported nanocomposite catalyst, which comprises the following steps:

[0026] 1) Soak the wire mesh at room temperature for 0.1-20 hours with 0.02-5 mol / L acid (hydrochloric acid, nitric acid, sulfuric acid, phosphoric acid or acetic acid) aqueous solution, and then soak it in octadecylamine at 60-200°C for 0.1-20 hours , then washed with ethanol, dried for later use;

[0027] 2) The "metal-metal oxide" nanocomposite is synthesized by the octadecylamine synthesis method, 1-50 ml of octadecylamine is weighed, heated to 100-300 ° C, and then the metal salt raw materials are added for stirring, and finally the "metal-metal oxide" is obtained. - Metal oxides" nanocomposites;

[0028] 3) Disperse the "metal-metal oxide" nanocomposite in cyclohexane, and then load it on the wire mesh processed in step 1) by an equal volume dipping method, and dry it at 50-150 ° C, Finally, the catalyst is obtained.

...

Embodiment 1

[0032] This example provides wire mesh supported "Ag nanoparticles and Cu with equal particle size" 2 Preparation of O-nanoparticle composites" catalysts.

[0033] Ag nanoparticles and Cu with equal particle size 2 The preparation method of the O nanoparticle composite is: weigh 10 ml of octadecylamine, heat it to 200 ° C, and then add a certain amount of AgNO 3 and Cu(NO 3 ) 2 , stirred at this temperature for 10 minutes, and finally obtained Ag nanoparticles and Cu nanoparticles with the same particle size. 2 O nanoparticle complexes.

[0034] The prepared nanocomposites are supported on a wire mesh by an equal volume impregnation method, and the wire mesh can be: stainless steel (SS-Gauze), aluminum (Al-Gauze), brass (HT-Gauze) or cupronickel ( BT-Gauze) wire mesh, wire diameter 0.1 to 2 mm.

[0035] Wire mesh supports "Ag nanoparticles and Cu with equal particle size" 2 O nanoparticle composite" catalysts are denoted as Ag-Cu, respectively 2 O / SS-Gauze, Ag-Cu 2 O / ...

Embodiment 2

[0037] This example provides the preparation of a "large CoO nanoparticle and small Ag nanoparticle composite" catalyst supported on a wire mesh.

[0038] The preparation method of the large CoO nanoparticle and small Ag nanoparticle composite is: weigh 10 ml of octadecylamine, heat it to 120 ° C, and then add a certain amount of Co(NO 3 ) 2 , heat up to 250°C, stir at this temperature for 10 minutes, then cool down to 120°C, add a certain amount of AgNO 3 , heated to 190 °C, and stirred at this temperature for 10 minutes to finally obtain a composite of large CoO nanoparticles and small Ag nanoparticles.

[0039] The prepared nanocomposites are supported on a wire mesh by an equal volume impregnation method, and the wire mesh can be: stainless steel (SS-Gauze), aluminum (Al-Gauze), brass (HT-Gauze) or cupronickel ( BT-Gauze) wire mesh, wire diameter 0.1 to 2 mm.

[0040] Wire mesh supported "large CoO nanoparticles and small Ag nanoparticles composite" catalysts are denote...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com