Device and method for removing film from green ceramic sheet

A green ceramic sheet and membrane device technology, which is applied in the manufacture of electrical components, circuits, semiconductors/solid-state devices, etc., can solve the problems of lower lamination efficiency and precision, difficulty in aligning layers, and dimensional changes, etc., to improve stacking Chip efficiency and accuracy, and the effect of improving alignment accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

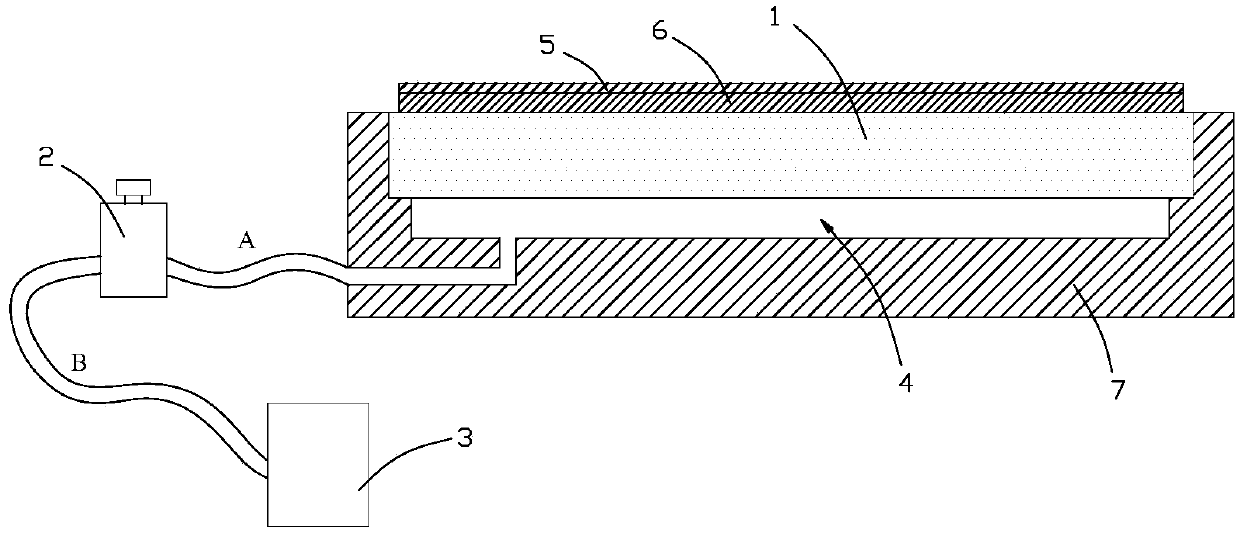

[0040] combine figure 1 As shown, a device for removing film from a green ceramic sheet includes a vacuum chuck 1 , a fluid control valve 2 and a vacuum generating device 3 . A sealed cavity 4 communicating with the lower surface of the vacuum chuck 1 is provided below the lower surface of the vacuum chuck 1 . The sealed cavity 4 is connected with the fluid control valve 2 through the pipeline A, and the fluid control valve 2 is connected with the vacuum generator 3 through the pipeline B.

[0041] Through the above design, it can be ensured that the green ceramic sheet 6 can be adsorbed on the upper surface of the vacuum chuck 1 .

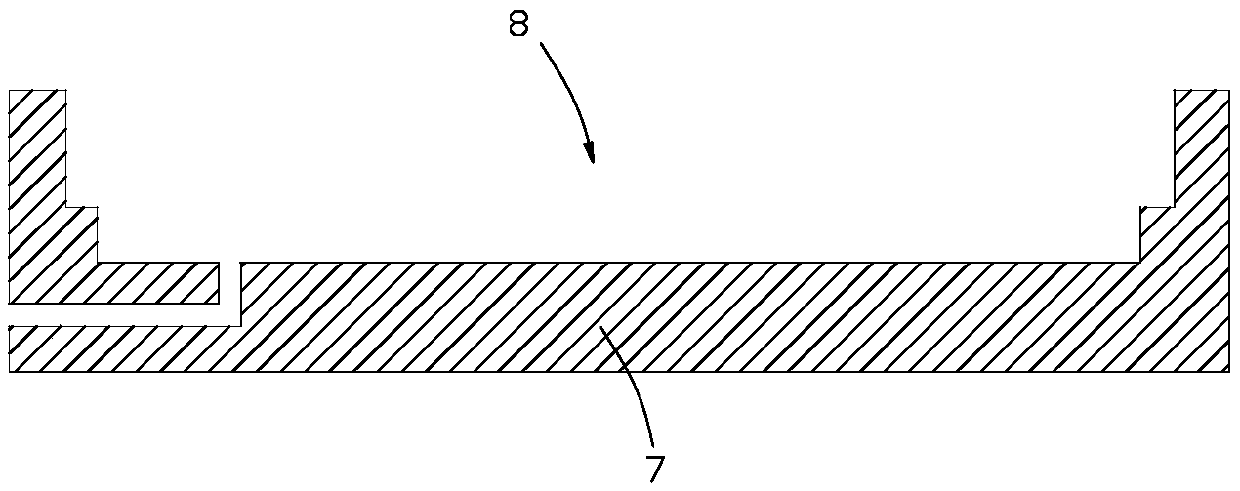

[0042] Specifically, such as figure 2 As shown, the film removal device also includes a vacuum suction cup placement platform 7, on which a groove 8 with a shape and a size adapted to the vacuum suction cup is provided on the vacuum suction cup placement platform 7, and when the vacuum suction cup is placed in the groove 8, A sealed cavity 4 i...

Embodiment 2

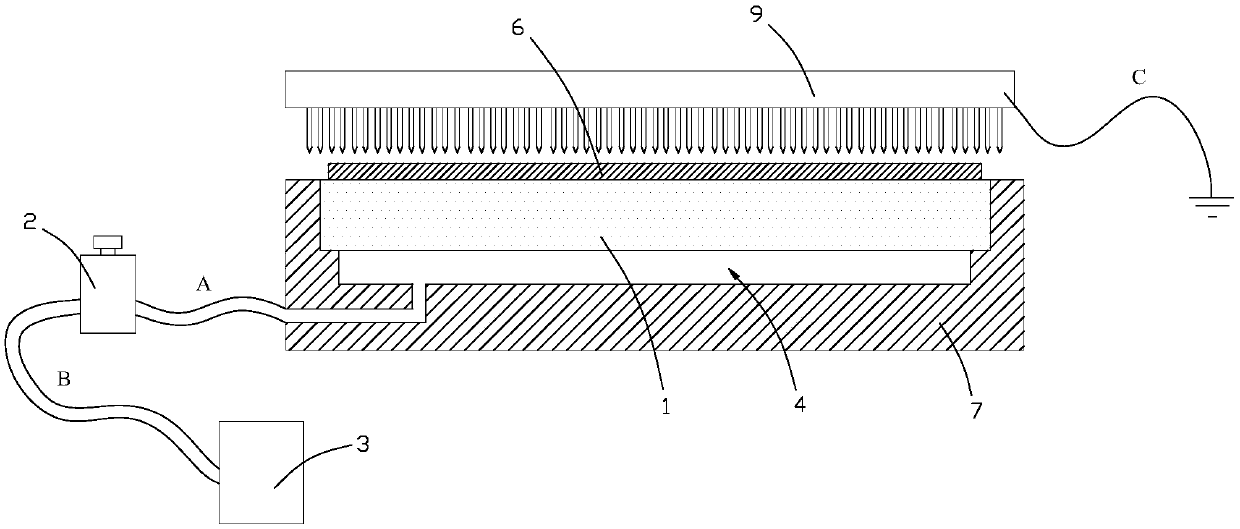

[0049] combine image 3 As shown, except that the following technical features of this embodiment 2 are different from those of the reference document 1, other technical features can refer to the above-mentioned embodiment 1.

[0050] The film removing device in this embodiment 2 also includes a static elimination brush 9, which is used to eliminate static electricity generated on the surface of the green ceramic sheet 6 after removing the polyester film 5, which is beneficial to improving the lamination efficiency and accuracy.

[0051] Specifically, the electrostatic elimination brush 9 is grounded through the metal wire C.

Embodiment 3

[0053] combine Figure 4 As shown, this embodiment 3 describes a method for removing the film of a green ceramic sheet, which is based on the device for removing the film of the green ceramic sheet in the above-mentioned embodiment 1, which includes the following steps:

[0054] a. Place the green ceramic sheet 6 flat on the upper surface of the vacuum chuck 1 so that the side to which the polyester film 5 is adhered faces upward, and adjust the position of the green ceramic sheet 6 so that it is aligned with the upper surface of the vacuum chuck 1;

[0055] b Turn on the vacuum generating device 3 and the fluid control valve 2, and the green ceramic sheet 6 is adsorbed on the upper surface of the vacuum chuck 1;

[0056] c separate the polyester film 5 from a corner of the green porcelain sheet 6, and separate the polyester film and the green porcelain sheet along the diagonal direction;

[0057] d Close the fluid control valve 2, and remove the green ceramic sheet 6.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com