Recycling method of scrap tinned copper rice

A treatment method, tin-plated copper technology, applied in the direction of electronic waste recycling, recycling technology, electrical components, etc., can solve the problems of high energy consumption and batch recycling, and achieve the effect of low cost, high-efficiency separation, and simple installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

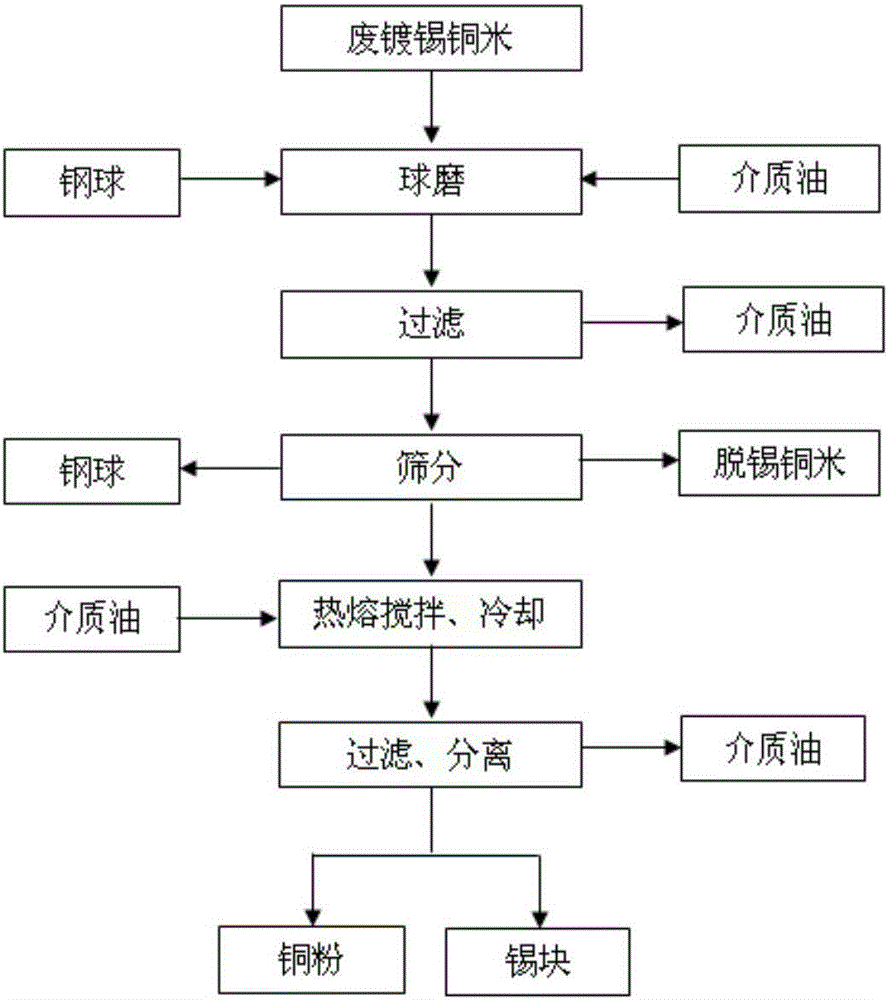

Method used

Image

Examples

Embodiment 1

[0028] Put 2kg of steel balls with a diameter of 20mm, 1kg of waste tin-plated copper rice with a wire diameter of 2-4mm and a length of 5-12mm, and 0.1kg of silicone oil into a vertical stirring ball mill, and process it at a speed of 300r / min for 30min; then ball mill Filter the product to obtain medium oil and solid product; sieve the solid product to obtain tin-copper mixed powder and copper rice after de-tinning; then put the tin-copper mixed powder into a container with a stirring device, add silicone oil, and put it in the container The silicone oil liquid level is 5cm higher than the accumulation height of the tin-copper metal powder in the container, then heat the container to 240°C, start the stirring device to stir for 3 minutes, stop heating and stirring, and filter the product in the container after the medium oil is cooled. Obtain silicone oil, copper powder, and tin block.

[0029] Technical effect: The tin plating layer on the surface of the waste tin-plated co...

Embodiment 2

[0031] Add 2kg of steel balls with a diameter of 20mm, 1kg of waste tinned copper rice with a wire diameter of 2-4mm and a length of 5-12mm, and 0.1kg of kerosene into a vertical stirring ball mill, and process it at a speed of 300r / min for 20min; then ball mill The product is filtered to obtain kerosene and solid products; the solid products are sieved to obtain tin-copper mixed powder and copper rice after detinning; then put the tin-copper mixed powder into a container with a stirring device, add kerosene, and the The kerosene liquid level is 5cm higher than the accumulation height of the tin-copper metal powder in the container, then the container is heated to 240°C, the stirring device is started to stir for 2 minutes, the heating and stirring are stopped, and the product in the container is filtered after the medium oil is cooled to obtain Kerosene, copper powder, tin block.

[0032] Technical effect: The tin plating layer on the surface of the waste tin-plated copper ri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wire diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com