Gasifier of low-temperature liquid

A low-temperature liquid and gasification device technology, applied in household refrigeration devices, gas/liquid distribution and storage, fixed-capacity gas storage tanks, etc., can solve the problem of reduced evaporation capacity of vaporizers, wasteful dissipation of cold energy, and heat transfer temperature differences Large and other problems, to achieve the effect of convenient use and simple installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

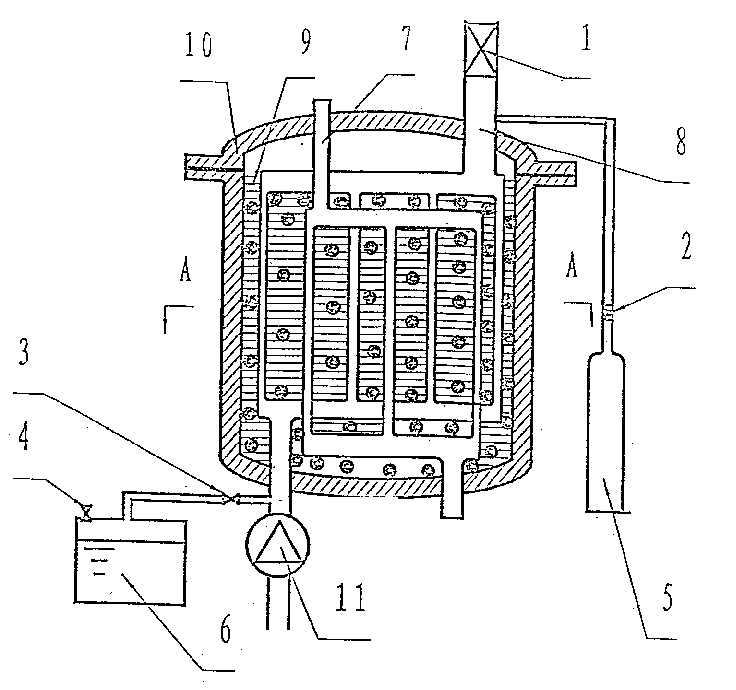

[0014] A gasification device for cold storage cryogenic liquid is made. Such as figure 1 As shown, the device includes: a cryogenic liquid heat exchanger 7, an adiabatic gasification box 10, a refrigerant heat exchanger 8, a cold storage medium 9, a circulation pump 11, an adiabatic storage tank 6 and a nitrogen cylinder 5; wherein, the cryogenic liquid Both the heat exchanger 7 and the refrigerant heat exchanger 8 are fixed in the adiabatic gasification box 10, their inlet pipes are fixed at the bottom of the adiabatic gasification box 10, and their outlet pipes are fixed at the top of the adiabatic gasification box 10, The entire adiabatic gasification box 10 is filled with a cold storage medium 9, the circulation pump 11 is fixedly connected to the inlet pipe of the refrigerant heat exchanger 8, and the heat insulation storage tank 6 is externally connected between the circulation pump 11 and the inlet pipe of the refrigerant heat exchanger 8 , the outlet pipe of the refri...

Embodiment 2

[0017] Utilize the device gasification liquefied natural gas of embodiment 1, concrete steps are as follows:

[0018] (1) The liquefied natural gas in the natural gas heat exchanger 7 gasifies and absorbs heat, and exchanges heat with the cold storage medium 9 on the shell side. The cold storage medium 9 cools down and freezes to release heat. Collected and sent to the gas supply device.

[0019] (2) In the cold storage medium 9 there are water polo with a freezing point of 0°C, salt water polo with a freezing point below zero, and Freon 111 balls with a freezing point of -36.5°C. These phase change balls freeze successively with the continuous cooling of the cold storage medium , to store the intermittent cooling capacity.

[0020] (3) Under the control of the circulating pump-valve linkage mechanism, the cooling capacity is taken out by the refrigerant flowing in the refrigerant heat exchanger 8 with the cold equipment freezer; the specific steps are as follows:

[0021] W...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com