High accurately measuring method for in-tube liquid level elevation of photoelectric and tubular settlement meter

The utility model relates to a water-tube-type sedimentation instrument and a technology for elevation measurement, which is applied in the measurement field and can solve the problems of low precision and large workload, and achieves the effect of simple device and convenient implementation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention is described in further detail below in conjunction with accompanying drawing:

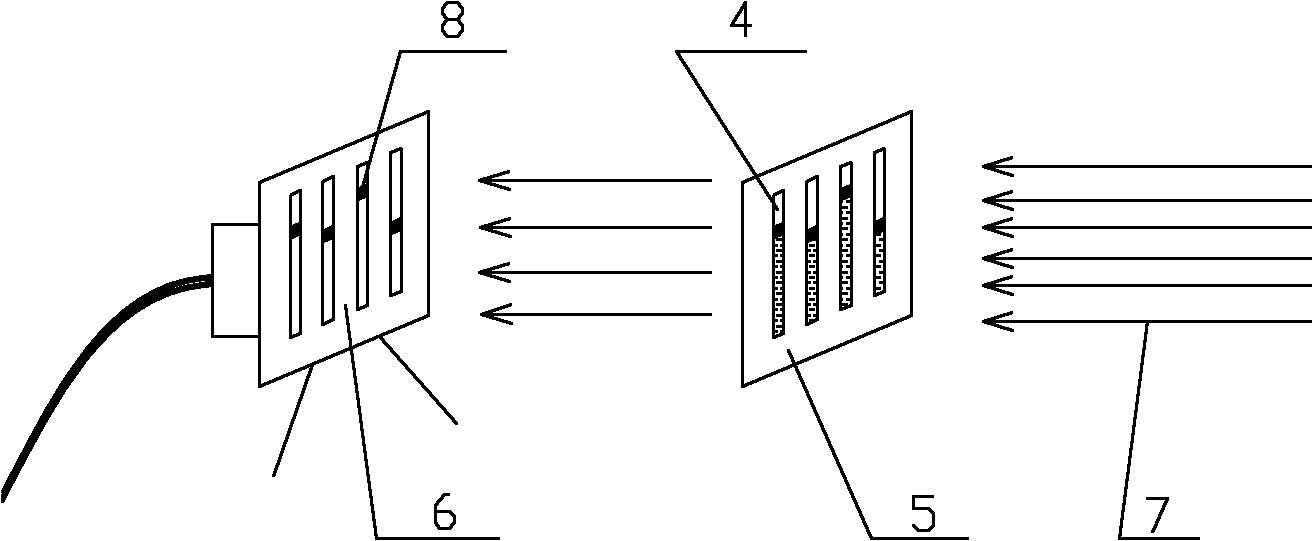

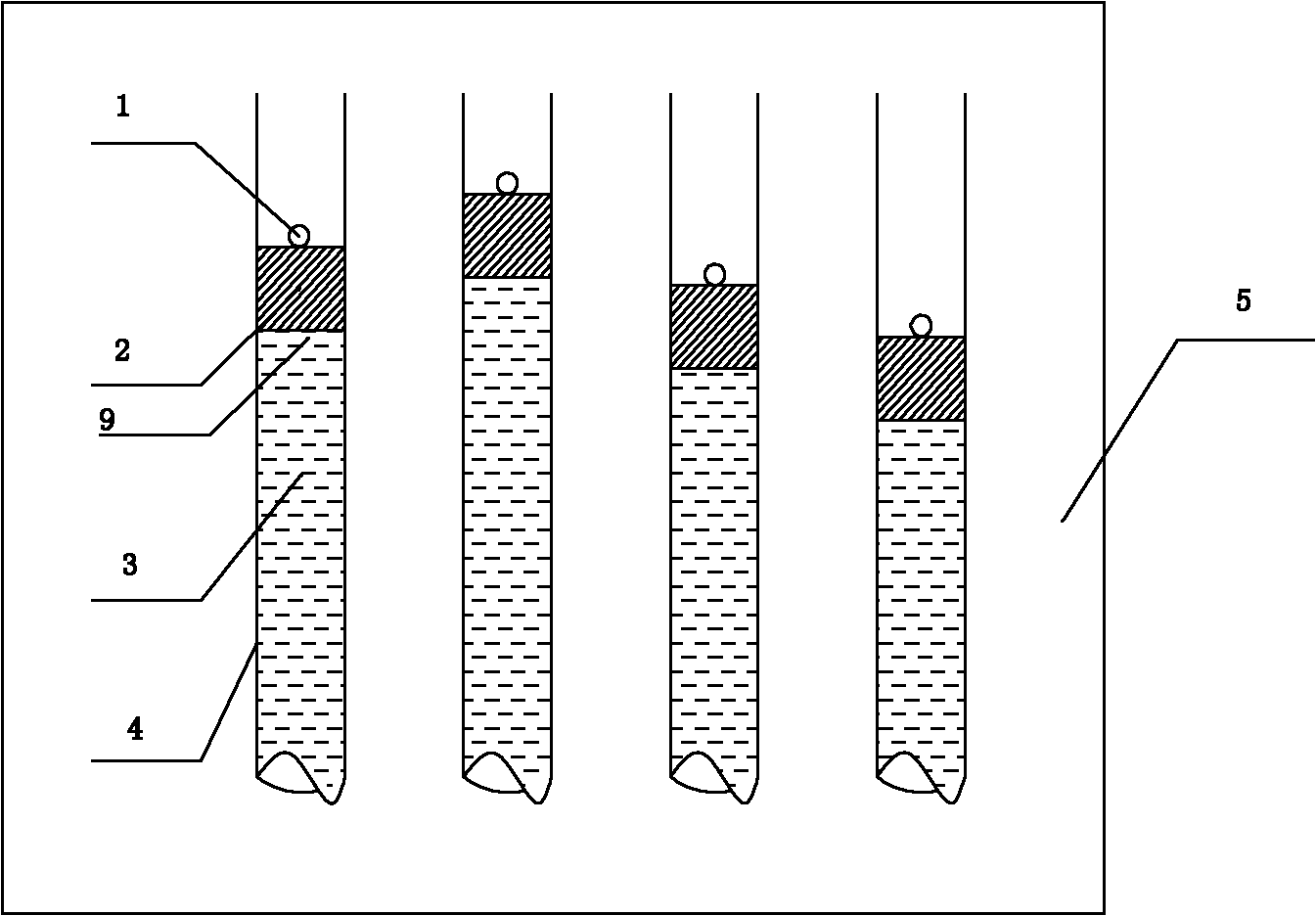

[0028] see figure 1 and figure 2Shown is a schematic diagram of a method, principle and device for measuring the difference in liquid level in a pipe with a water pipe-type sedimentation instrument. It is composed of a light source 1, a float 2, a measuring tube 3 and the liquid 4 inside it, and an observation platform 5, etc. The measuring tube 4 is installed on the observation platform 5, and the measuring tube is connected with the hydraulic tank. The hydraulic tube is an essential part of the settlement instrument. Since all water tube type settlement instruments have this device, it is not shown here. After that, the electric valve can be used to automatically control the liquid addition to the settling side head and the measuring tube in the observation room. After the hydraulic pressure in the measuring tube remains constant, place the float 2 in the measurin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com